Method and device for testing thermal circulation parameters of laser welding

A technology of laser welding and testing method, applied in laser welding equipment, measuring device, welding equipment and other directions, can solve the problems of complex system, achieve the effect of fast acquisition and conversion, fast response speed, convenient storage and display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

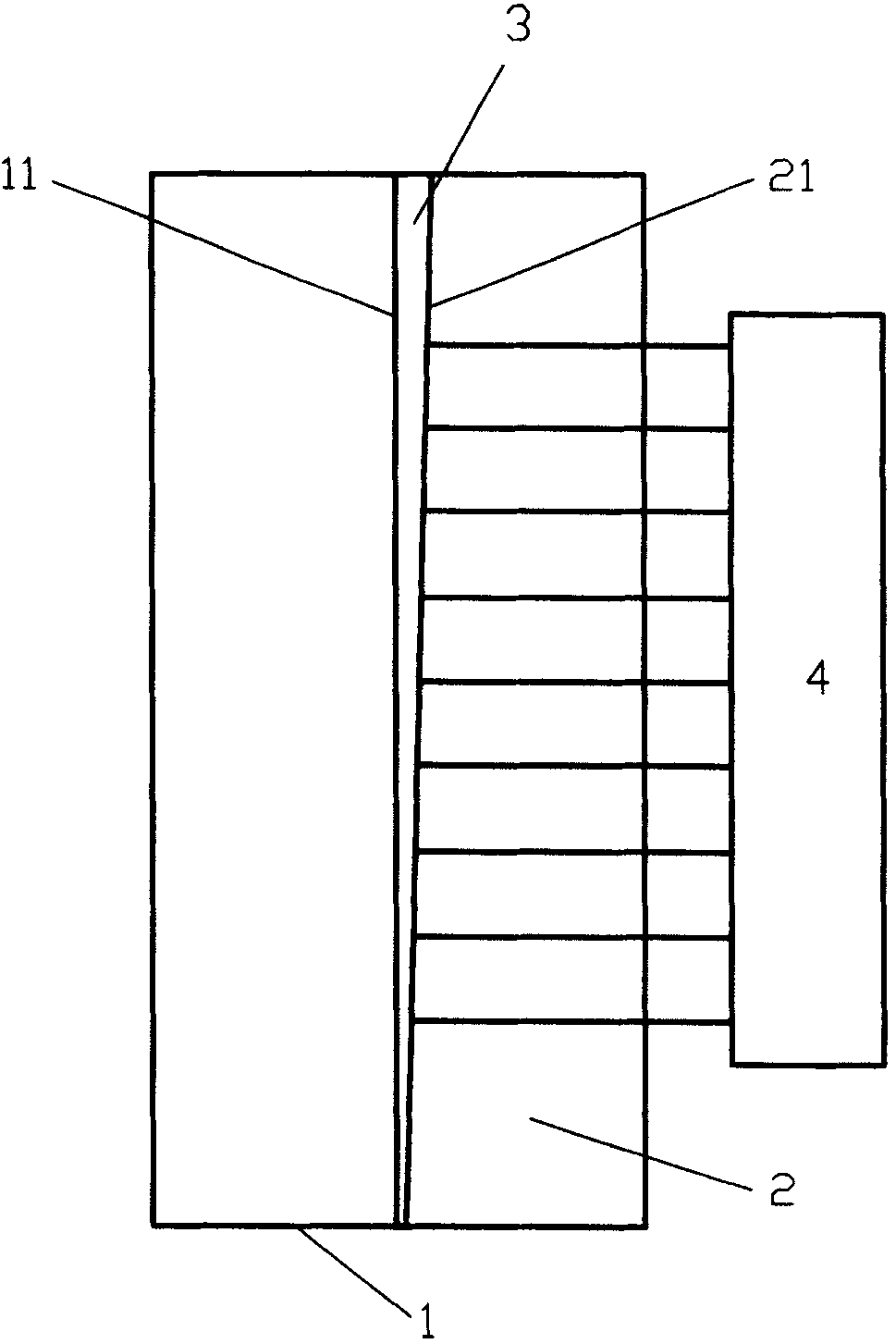

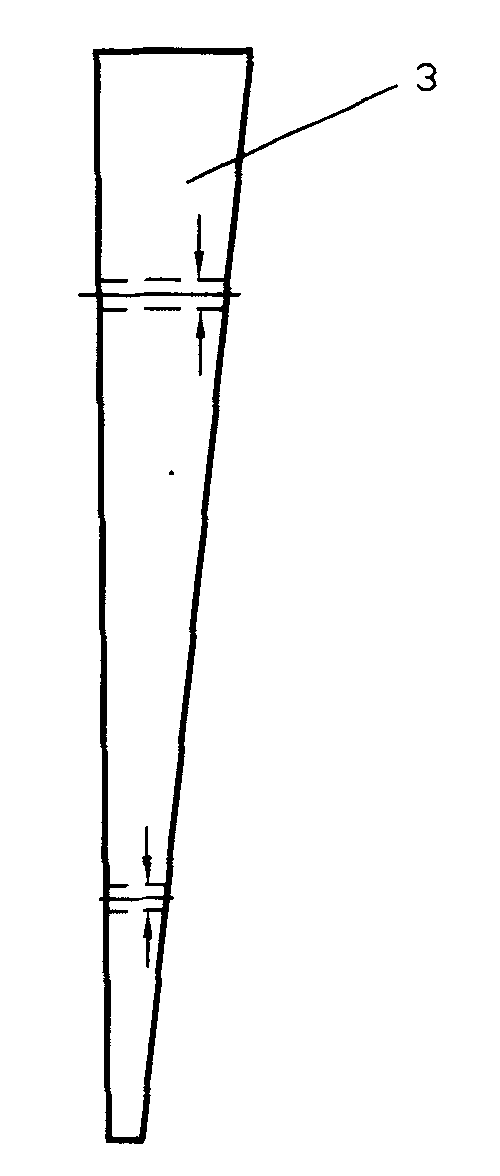

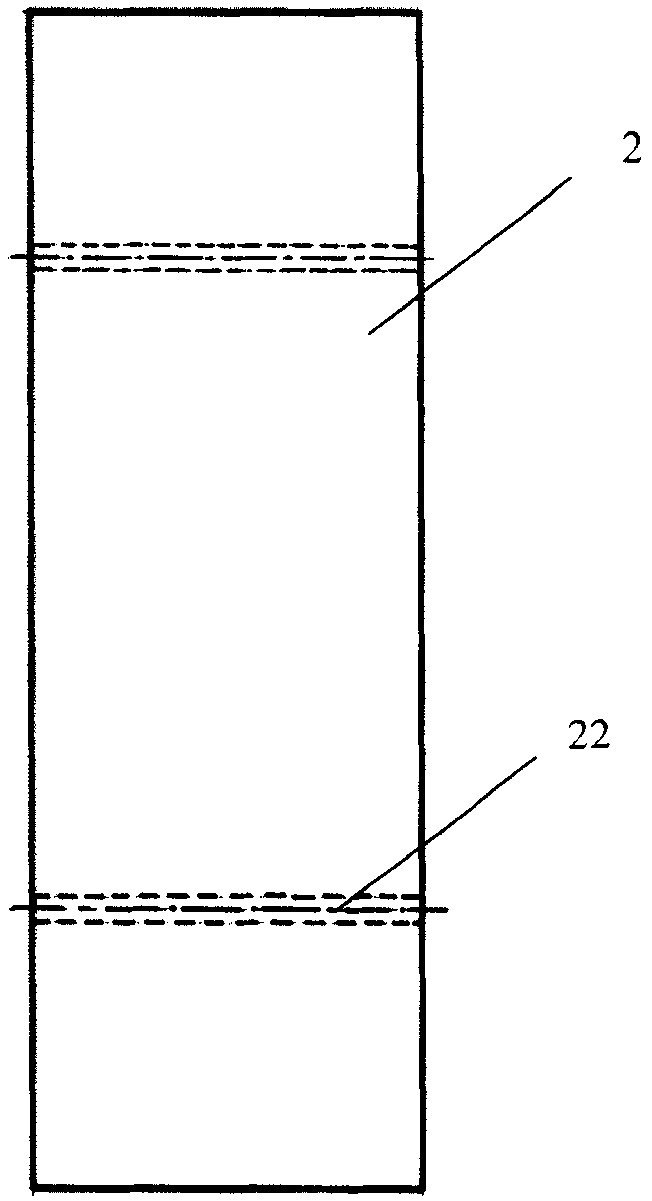

[0027] see Figure 1 ~ Figure 4 , the testing method of laser welding heat cycle parameter of the present invention, first place a wedge-shaped bar 3 between two welding test plates 1,2, the end face 21 of welding test plate 2 corresponding to the inclined plane of wedge-shaped bar 3 is used as the temperature measuring surface, The end face 11 of the welding test plate 1 corresponding to the plane of the wedge-shaped strip 3 is used as the welding surface, and a number of through holes 22 for placing thermocouples are evenly distributed along the end face 21 of the welding test plate, and the thermocouple 4 is arranged accordingly, and the wedge-shaped strip 3 is connected to the thermocouple. The temperature measuring surface of the pair 4 is kept tightly connected; the temperature measuring surface is at a certain angle to the laser welding seam metal; then, the bottom of the wedge-shaped strip 3 is used as the welding start end, and the top of the wedge-shaped strip 3 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com