Molded cap ball composite heating agent and production process thereof

A technology of exothermic agent and sphere, which is applied in the field of metallurgy, can solve problems such as low heating temperature and weakened reaction speed, and achieve the effect of secondary feeding and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

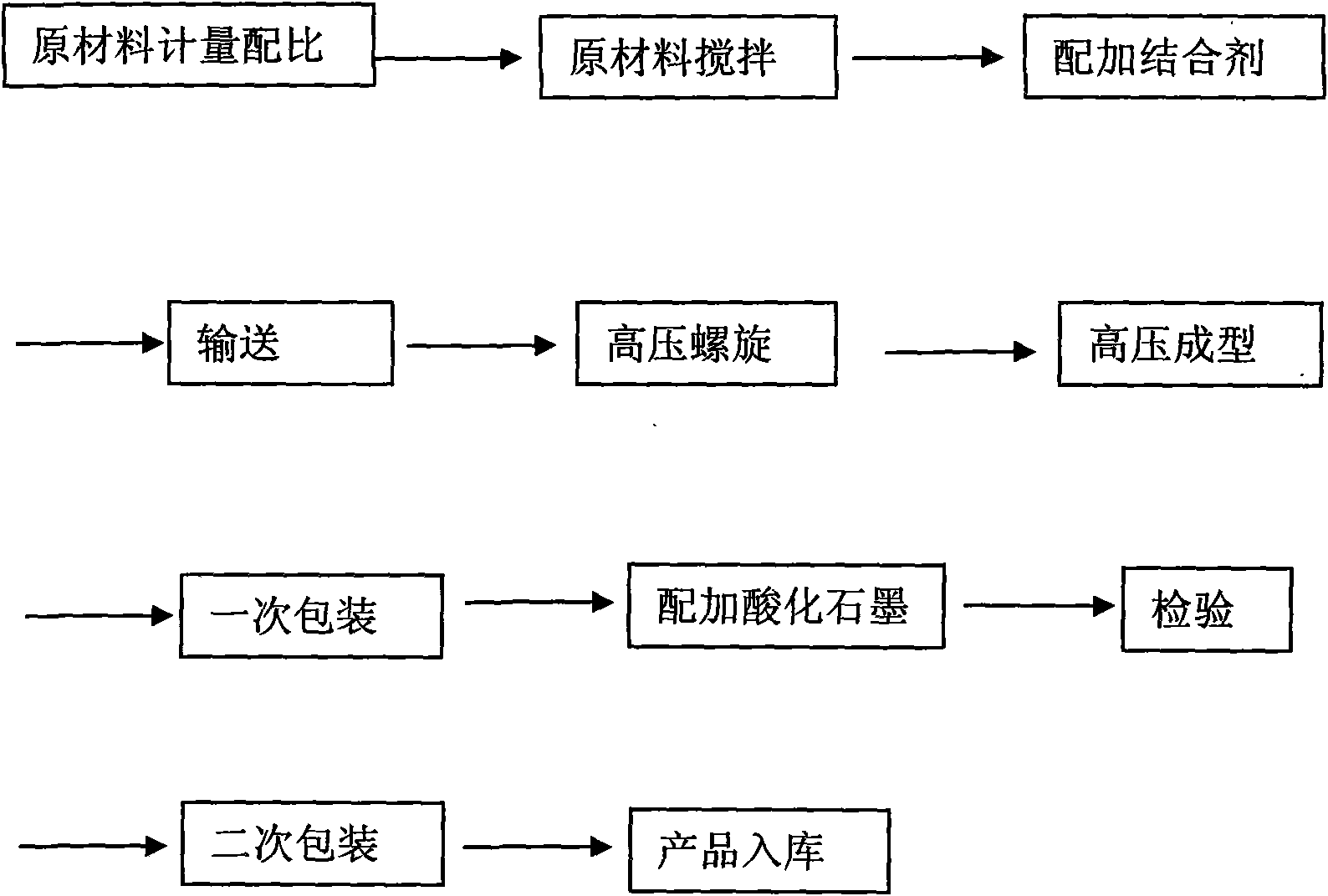

Image

Examples

Embodiment 1

[0024] Embodiment 1: The composite type exothermic agent of die-cast cap mouth sphere of the present invention is processed by the raw material of following percentage by weight: aluminum powder 15%, sodium nitrate 8%, iron oxide powder 49%, fluorite powder 22% , Acidified graphite 6%.

Embodiment 2

[0025] Embodiment 2: The compound type exothermic agent of die-cast cap mouth sphere of the present invention is processed by the raw material of following percentage by weight: aluminum powder 18%, sodium nitrate 10%, iron oxide powder 41%, fluorite powder 23% , Acidified graphite 8%.

Embodiment 3

[0026] Embodiment 3: The mold-cast cap mouth sphere composite type exothermic agent of the present invention is processed by the raw material of following percentage by weight: aluminum powder 20%, sodium nitrate 13%, iron oxide powder 32%, fluorite powder 25% , Acidified graphite 10%.

[0027] For this reason, the production technology that the present invention takes is: aluminum powder, sodium nitrate, iron oxide powder, fluorite powder, acidified graphite raw material of described weight ratio are mixed, accurately metered according to technical ratio scheme (every batch of total weight is 500kg ) were transported to the planetary mixer and stirred for 20 minutes, and then according to the technical plan, the organic binder was accurately measured and sent into the planetary mixer to continue stirring for 30 minutes, and the qualified mixture was transported to the high-pressure screw machine through the conveyor belt. The mixed material is pressed into the spherical mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com