Method for removing the thermal compression welding of copper-aluminum combined pipeline fitting under the assistance of rotary friction

A rotary friction and hot-press welding technology, which is applied in welding equipment, welding/welding/cutting objects, applications, etc., can solve the problems of low yield and poor connection compactness, and achieve high yield, low cost, and simplified assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

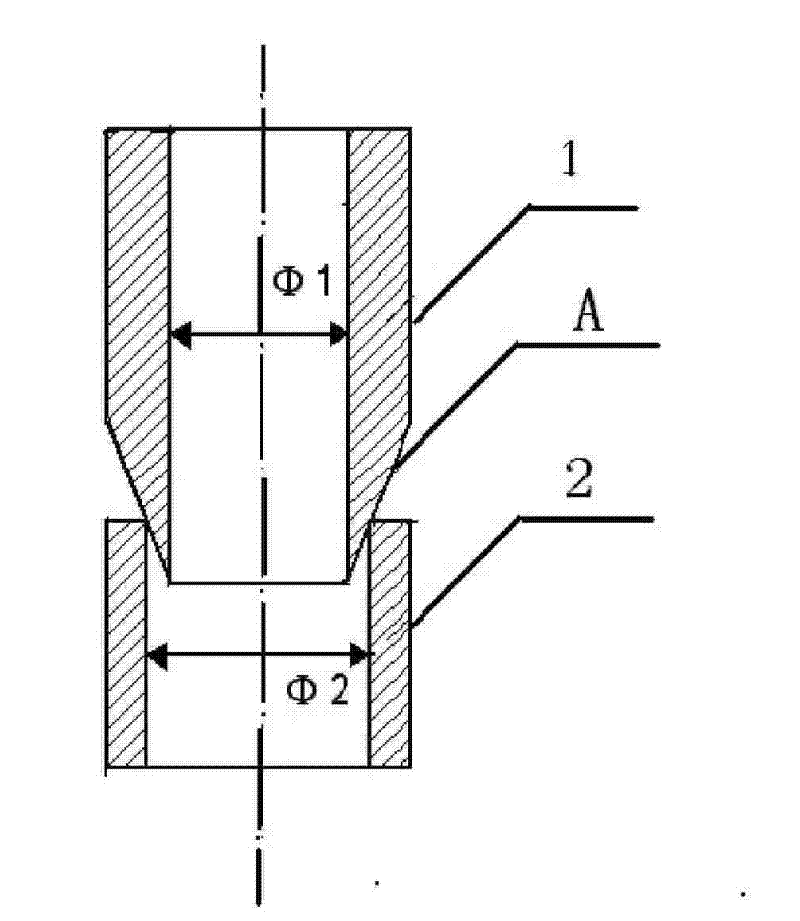

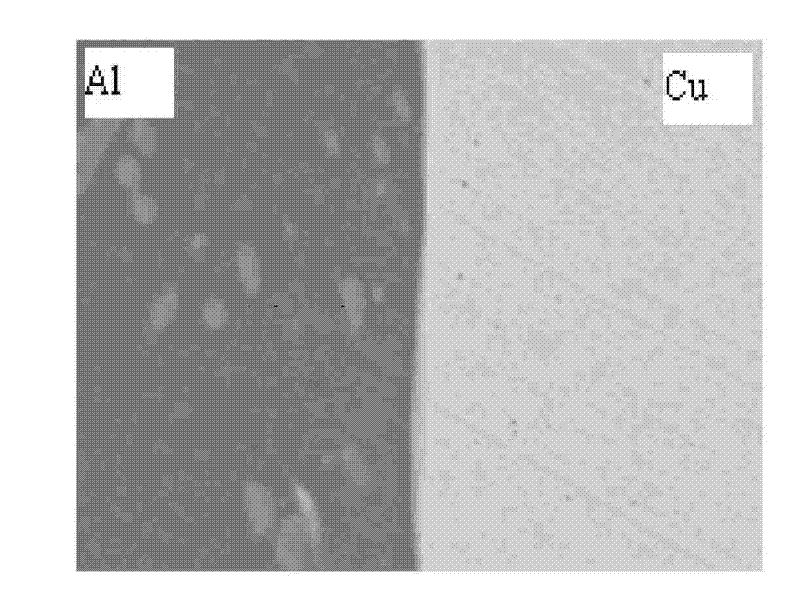

[0011] Specific implementation mode one: the following combination figure 1 Describe this specific implementation mode, a method for hot-press welding of copper-aluminum composite pipeline parts assisted by rotation friction, the method is realized by the following steps:

[0012] Step 1: Process the outer wall of one end of the copper pipe 1 to be welded into a tapered surface A, the cone angle of the tapered surface A is 5°-10°, the inner diameter Φ1 of the copper pipe 1 and the inner diameter of the aluminum pipe 2 The difference range of Φ2 is between 0mm and 1mm;

[0013] Step 2: Fix the copper tube 1 obtained in step 1 on the drill chuck of the drilling and milling machine, fix the aluminum tube 2 on the fixture of the drilling and milling machine workbench, and then fix the end of the copper tube 1 with the tapered surface A Insert one end of the aluminum tube 2, adjust the drill chuck of the drilling and milling machine, so that the axis of the copper tube 1 and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com