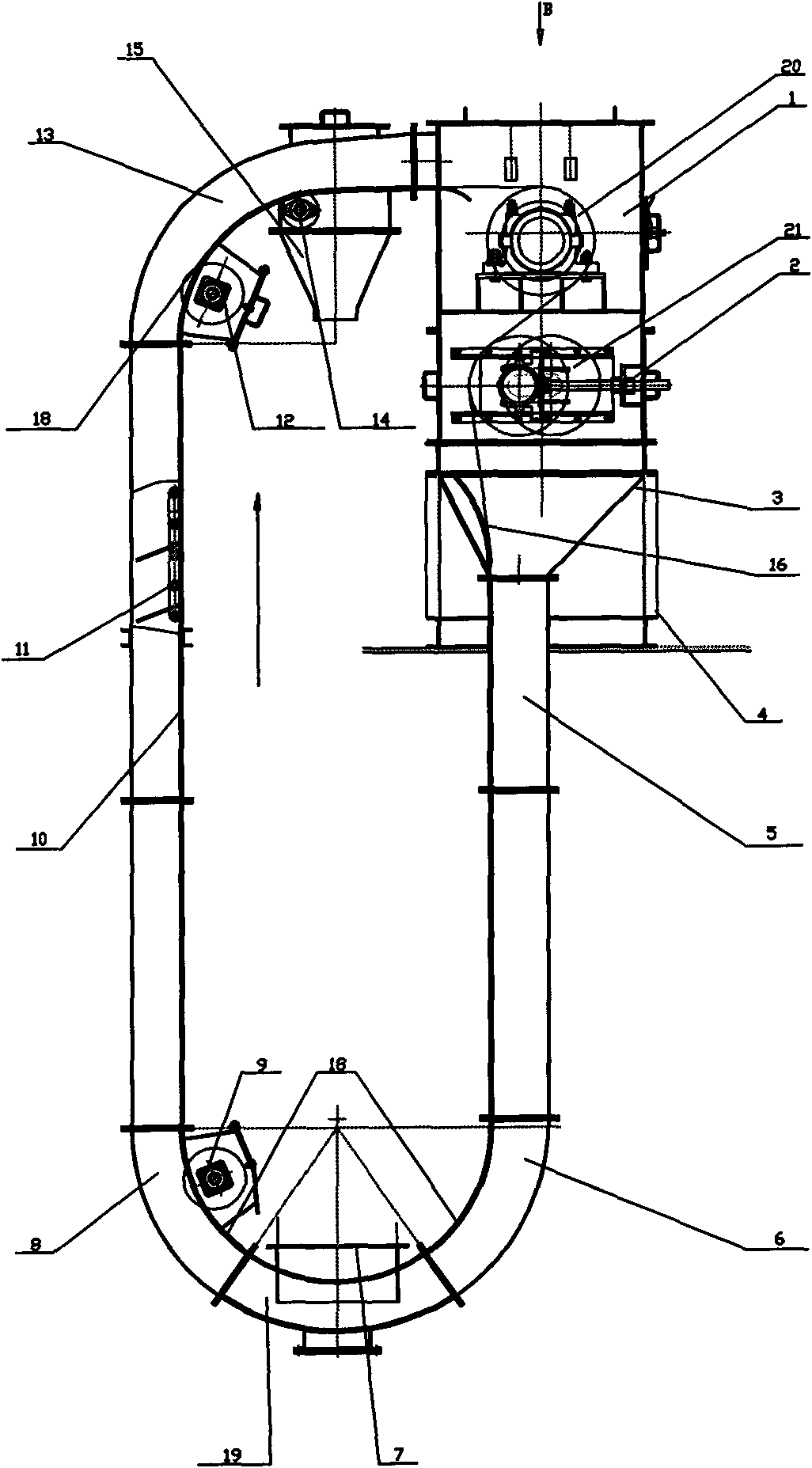

Great-circle vertical annular embedded scraper transporter

A buried scraper conveyor and arc façade technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of large size of elevator, inconvenient layout of structure and form, limited space for coke pusher, etc. , to achieve the effect of simple structure, reduced friction and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] like figure 1 In the middle, the material enters the closed rectangular section feeding curved section 19 from the lower feeding port 7, and is driven forward by the scraper chain 11, and is transferred to the carrying vertical section 10 through the carrying curved section 8 for lifting, and passes through the upper turning section 13 Enter upper discharge funnel 15 discharge. During the lifting process of the material, the lifting force generated by the scraper chain 11 along the moving direction overcomes the external friction resistance between the material and the tank wall and the gravity of the material itself, thereby being lifted, and the material is conveyed in a vertical plane.

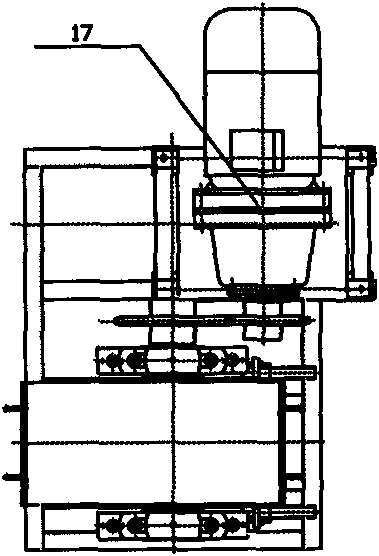

[0035] The operation of the scraper chain 11 is carried out like this: the driving device 17 drives the head wheel 20 to run, and under the traction of the head 1 head wheel, enters the tail 2, and the tail 2 is provided with a tensioning device, and the tail wheel 21 can also be Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com