Cage-locking, cage-stabilizing and overwinding and overfalling brake device for of skip of cage of vertical shaft

A braking device and cage technology, which is applied in hoisting devices, transportation and packaging, lifting equipment in mines, etc., can solve the problems of large up and down movement, and achieve the effect of convenient installation and debugging, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

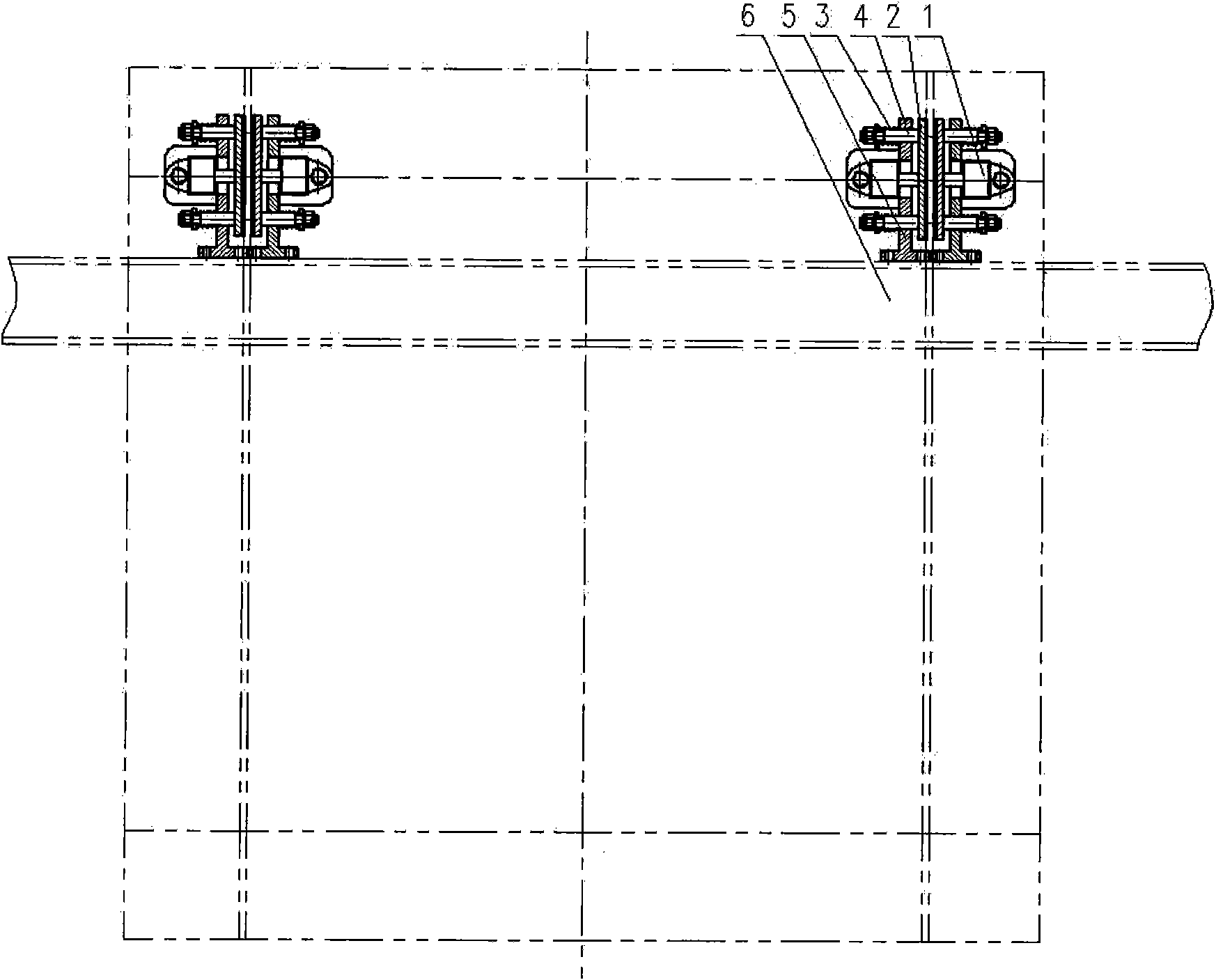

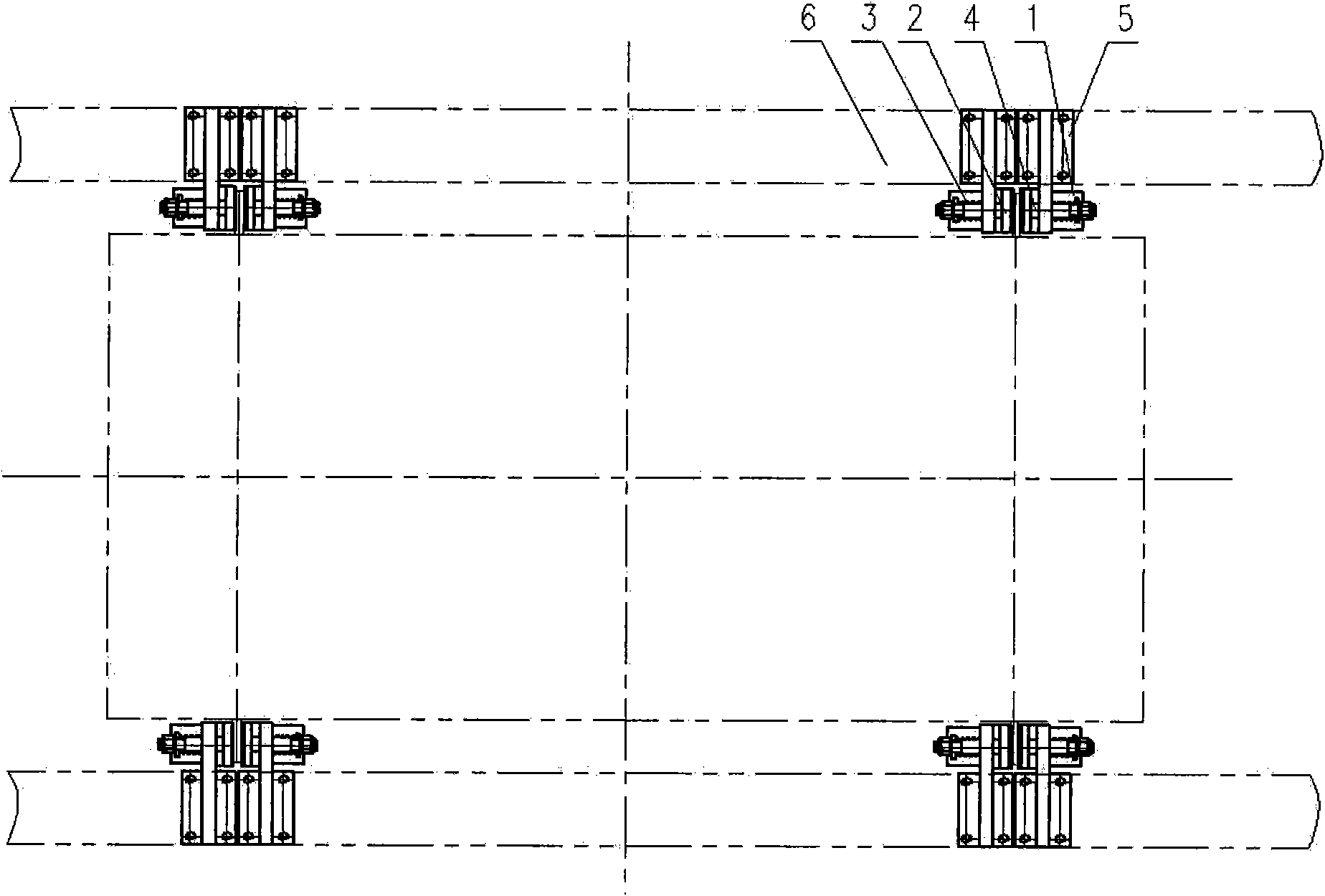

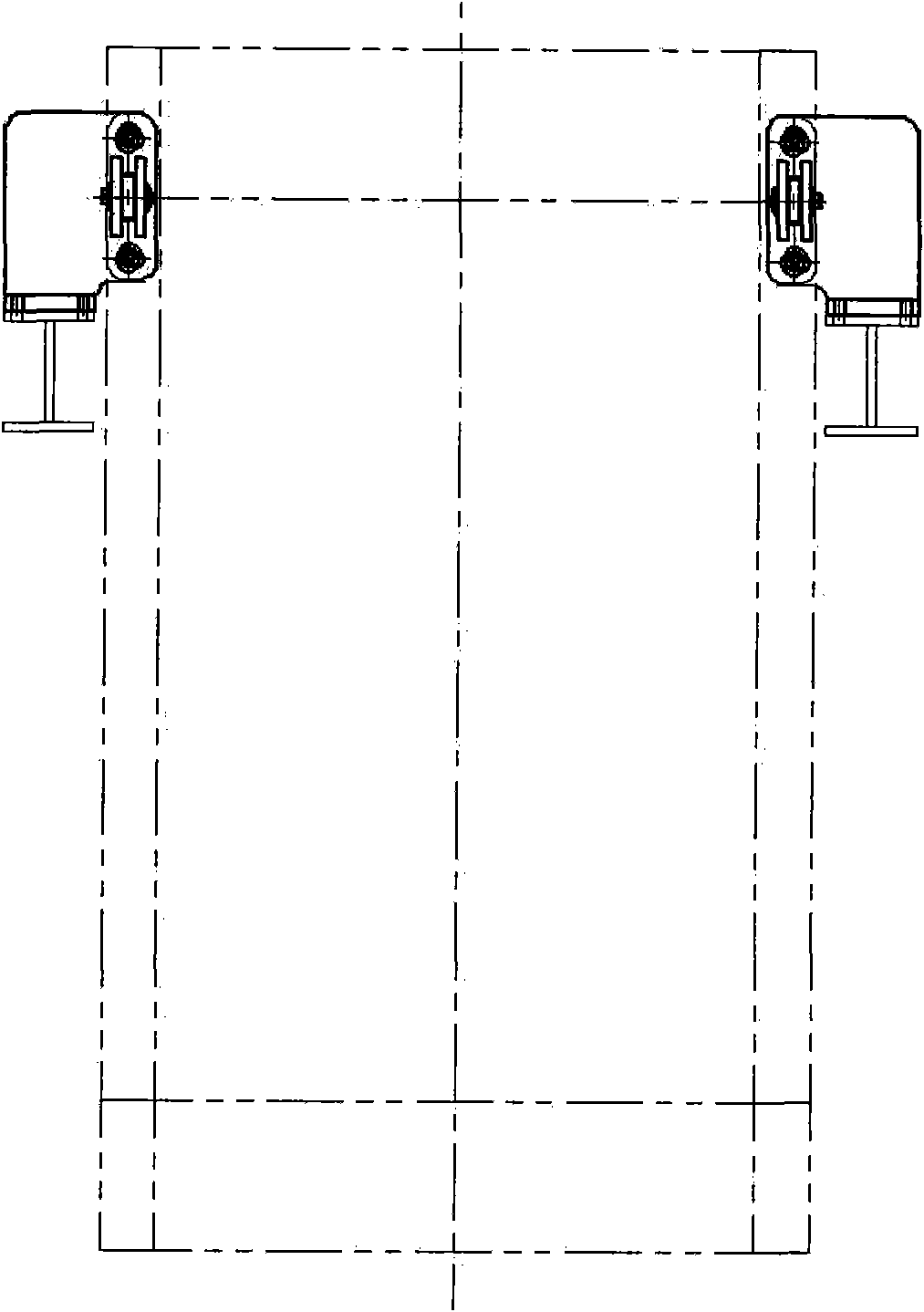

[0022] Vertical well cage skip lock tank stabilizer and over-rolling and over-discharging brake device, which consists of brake cylinder (1), brake plate and friction lining (2) brake release spring (3) bearing pin (4) support (5 ), installation beam (6), hydraulic servo system and electric control system (7). It is characterized in that: the brake plate is installed on the lifting container, the width of the brake plate is 180mm, the thickness is greater than 30mm, and the length is the same as the height of the lifting container. The brake cylinder (1) is installed on the support (5) with a pin shaft; the brake plate and friction lining (2) brake release spring (3) bearing pin (4) are installed on the support (5); The seat (5) is connected to the mounting beam (6) by welding or bolts. The device is normally open, with hydraulic cylinders t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com