LED lamp radiator with heat tube function and combined LED illumination lamp

A technology for LED lamps and radiators, applied in lighting devices, lighting and heating equipment, cooling/heating devices for lighting devices, etc., can solve the problems of high cost, poor heat dissipation, and large size of the heat dissipation body, so as to prolong the service life. , avoid light decay phenomenon, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

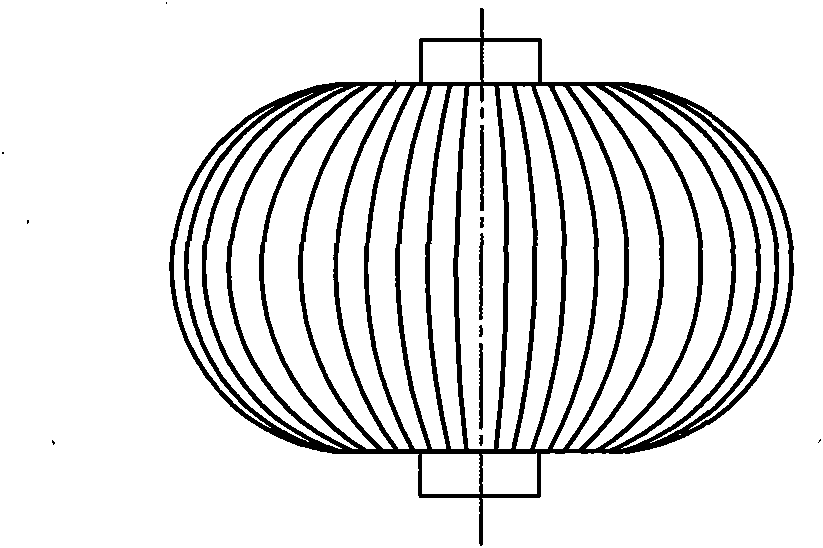

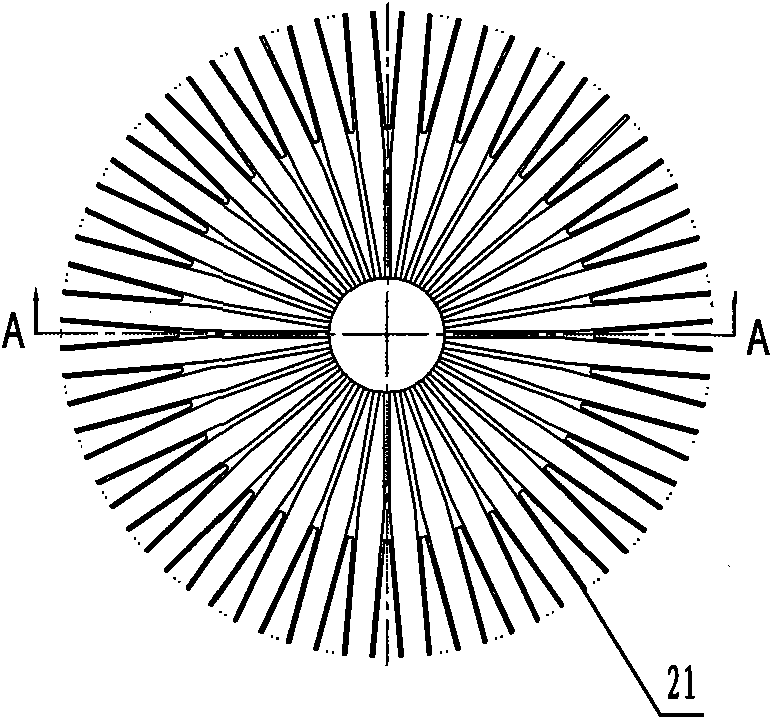

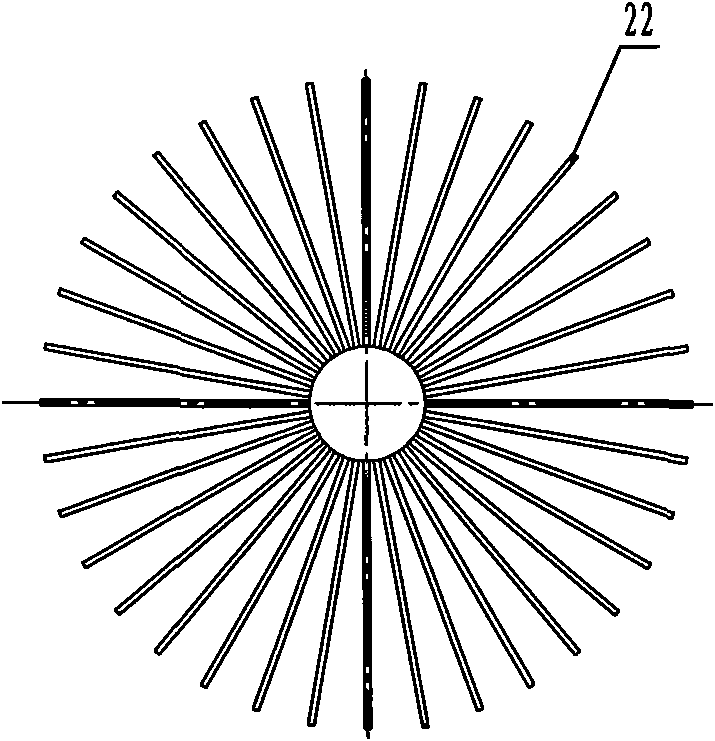

[0050] A heat sink for LED lights with heat pipe function, such as Figure 1 ~ Figure 2 As shown, the radiator includes heat dissipation fins 2, an installation connection body fixedly connected with the heat dissipation fins 2, and the installation connection body includes an installation base 3 and a center of the base, perpendicular to the base and with an inner hole. Cylinder 1, said cylinder 1 is a cylinder whose inner hole cross section is circular in shape, heat dissipation fins 2 are fixedly connected with the outer surface of cylinder 1, and are evenly distributed radially on cylinder 1 A heat sink with a spherical outer contour is formed on the outer circumference of the outer circumference; the tail end of each heat dissipation fin has a bifurcation (see figure 2 ), the heat dissipation fins 2 and the installation connecting body composed of the installation base 3 and the cylinder 1 with an inner hole in the center of the base are integrally die-cast into one, and...

Embodiment 2

[0057] Single LED lighting fixture, a single projection lamp consisting of a group of LED light sources with LED lamp radiators. Such as Figure 14 ~ Figure 15 As shown, the lighting fixture includes an LED lamp radiator and an LED light source 2. The LED lamp radiator is the LED lamp radiator 3 with heat pipe function described in Embodiment 1, and is mainly connected by heat dissipation fins 32 and installation body, the installation connecting body includes an installation base 33 and an installation column 31 located at the center of the base, perpendicular to the base and with an inner hole, the installation column 31 is a cylinder whose inner hole cross section is circular in shape, Radiating fins 32 are fixedly connected to the outer circumference of the mounting cylinder 31, and are distributed radially evenly on the outer circumference of the cylindrical mounting cylinder 31 to form a hexagonal cylinder whose cross section is a hexagon ( see Figure 14 , Figure 15...

Embodiment 3

[0063] A super-high-power combined LED lighting fixture.

[0064] Such as Figure 17 As shown, the ultra-high-power combined LED lighting fixture is composed of 7 groups of LED light sources with LED lamp radiators, and each group of LED light sources has an LED lamp radiator with heat pipe function as described in Embodiment 1. Each The shape of the LED lamp radiator 3 with heat pipe function is a cylinder with a hexagonal cross section, and there are 7 hexagonal cross section LED lamp radiators 3 with a heat pipe function. The frame-type fixing frame 4, the lamp bracket 5 and the fixing frame 4 are connected in a hinged manner, which becomes a super-high-power combined LED lighting fixture composed of 7 groups of LED light sources with heat pipe function LED lamp radiators——7 heads Projection lights. By changing the angle between the fixing frame 4 and the lamp bracket 5, the illumination angle can be changed arbitrarily.

[0065] In this embodiment, in each group of LED ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com