Method for detecting fault of rotating diode

A rotating diode and fault detection technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of inability to distinguish magnetic flux changes, inaccurate measurements, high misoperation rate or refusal rate, and achieve Guarantee the effect of normal and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

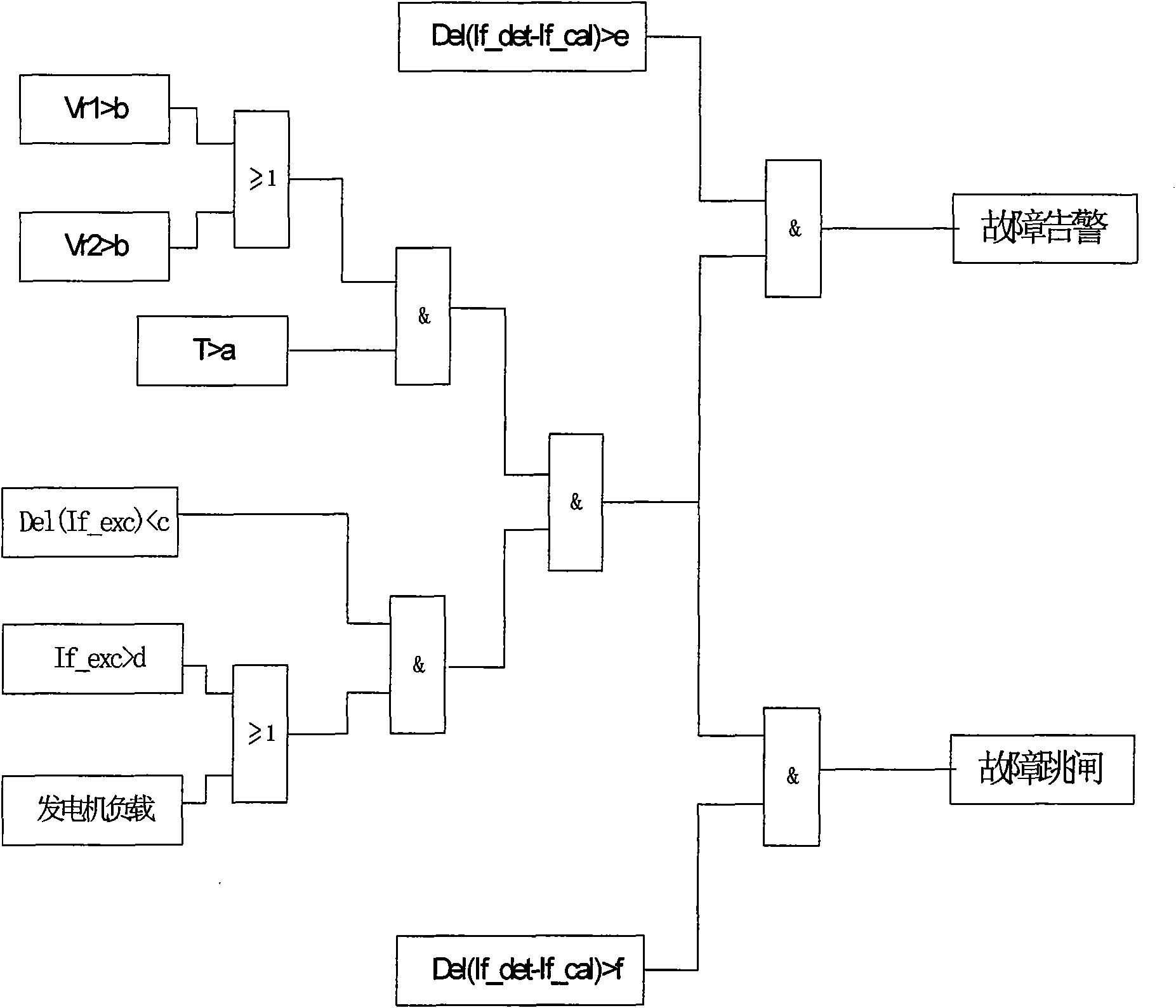

[0033] The specific implementation method of the present invention is as shown in Figure 1: among the figure V r1 For harmonic rms characteristic measurements 1, V r2 Harmonic RMS characteristic measurement 2, If_exc is the current measurement value of the excitation device, If_det is the actual value of the field winding current of the exciter, If_cal is the calculated value of the field winding current of the exciter, T is the delay time, a, b, c, d , e, f are the tuning parameters, which are set according to the excitation system parameters.

[0034] 1. The harmonic current in the excitation winding is detected by two sensors with different principles: DC shunt measurement method and Luo coil measurement method. Collect two exciter excitation winding currents, analyze and calculate them through FFT (FastFourierTransform, Fast Fourier Transform) respectively, and obtain the characteristic measurement of harmonic RMS 1 (V r1 ) (measurement of the excitation winding current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com