Method for manufacturing metal connecting line

A manufacturing method and metal wiring technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor reliability and low performance of metal interconnecting wires, reduce compressive stress, and ensure electronic stability. , The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose and features of the present invention more obvious and understandable, the present invention will be further described by giving preferred embodiments and in conjunction with the accompanying drawings.

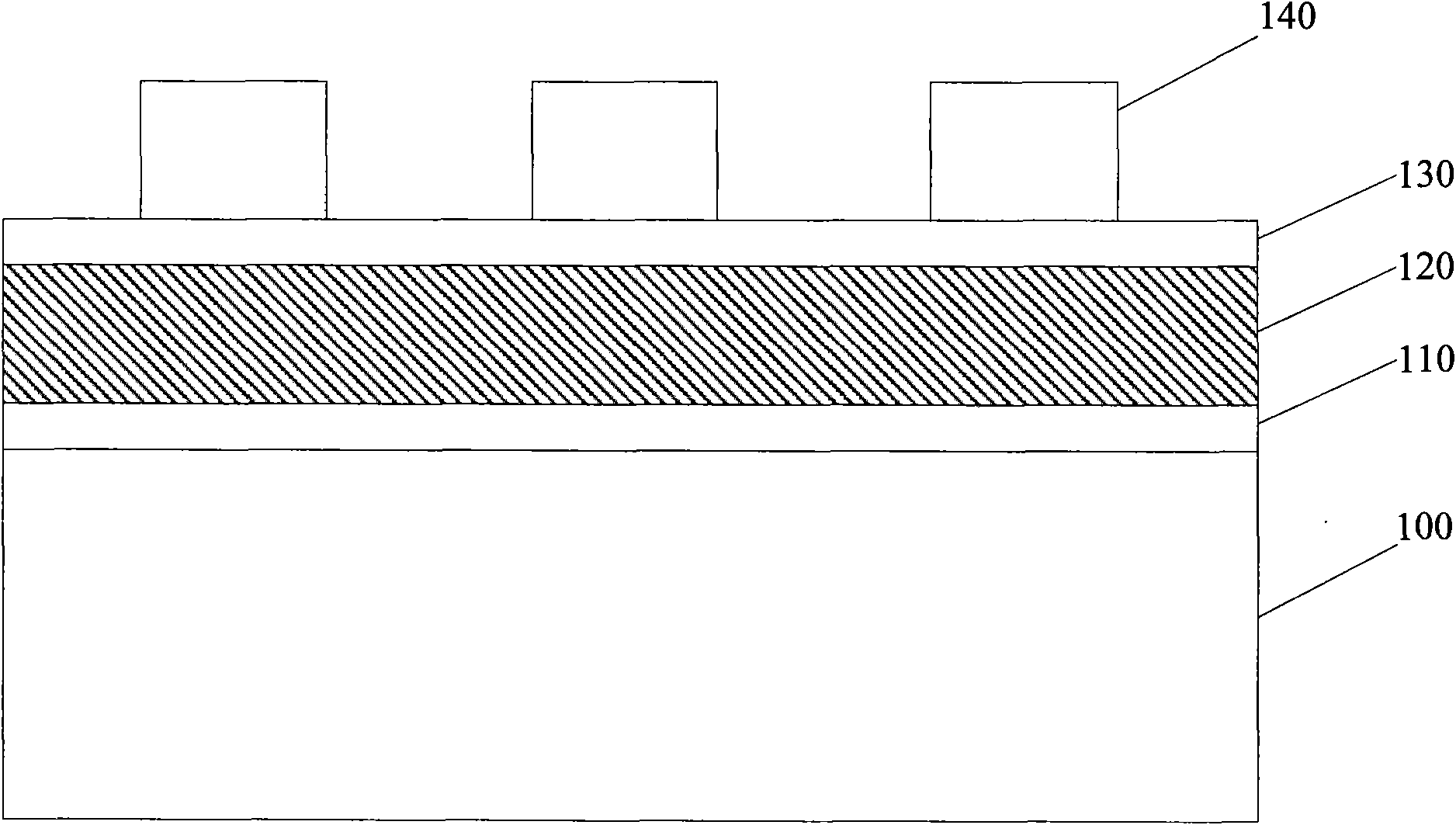

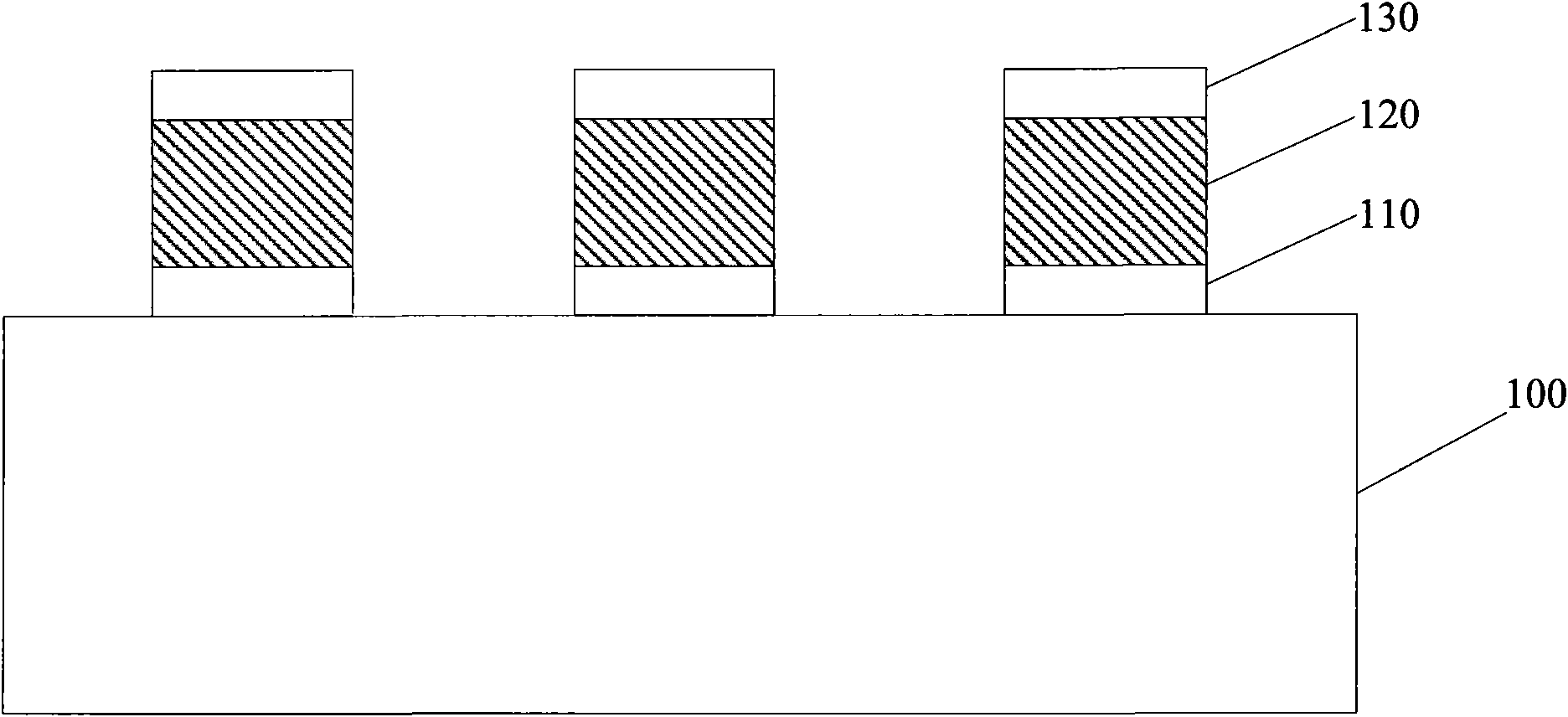

[0037] See image 3 , which is a flowchart of a method for manufacturing a metal wiring provided by an embodiment of the present invention. The manufacturing method includes:

[0038] S310: Provide a semiconductor substrate;

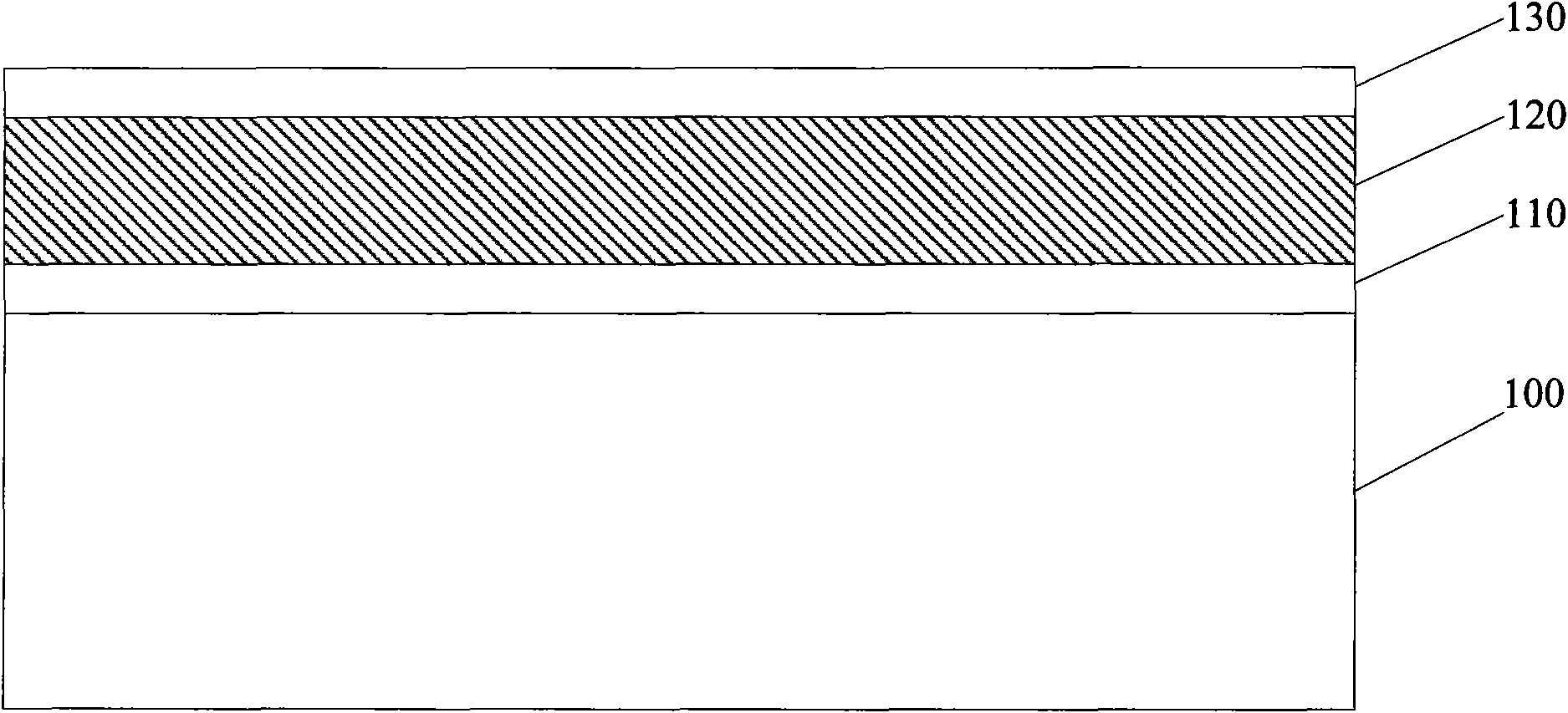

[0039] S320: forming a barrier layer on the substrate;

[0040] In this embodiment, the barrier layer is a titanium nitride (TiN) layer. There is a first adhesive layer between the barrier layer and the substrate. The first adhesion layer is a titanium (Ti) layer.

[0041] The role of the Ti layer is as an adhesion layer between the dielectric layer and the metal layer to provide better adhesion between the two layers of materials, while the TiN layer is used as a barrier layer to avoid Ti and the metal layer, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com