Motor control system for oil extractor in oil field

A technology of motor control and pumping unit, which is applied in the control system, vector control system, motor generator control, etc., can solve the problems of unfavorable energy saving and large energy loss, improve reliability and stability, save energy, The effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

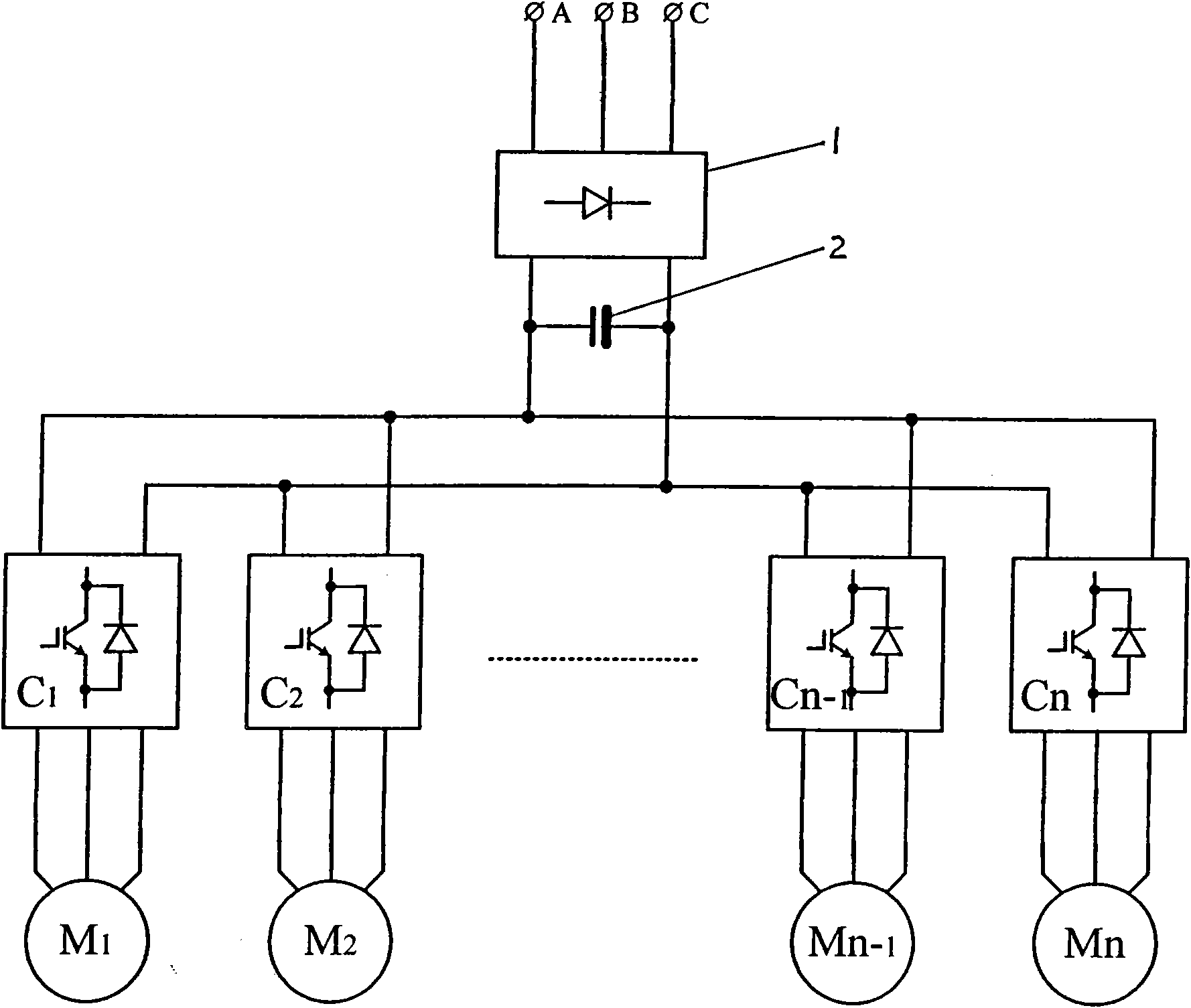

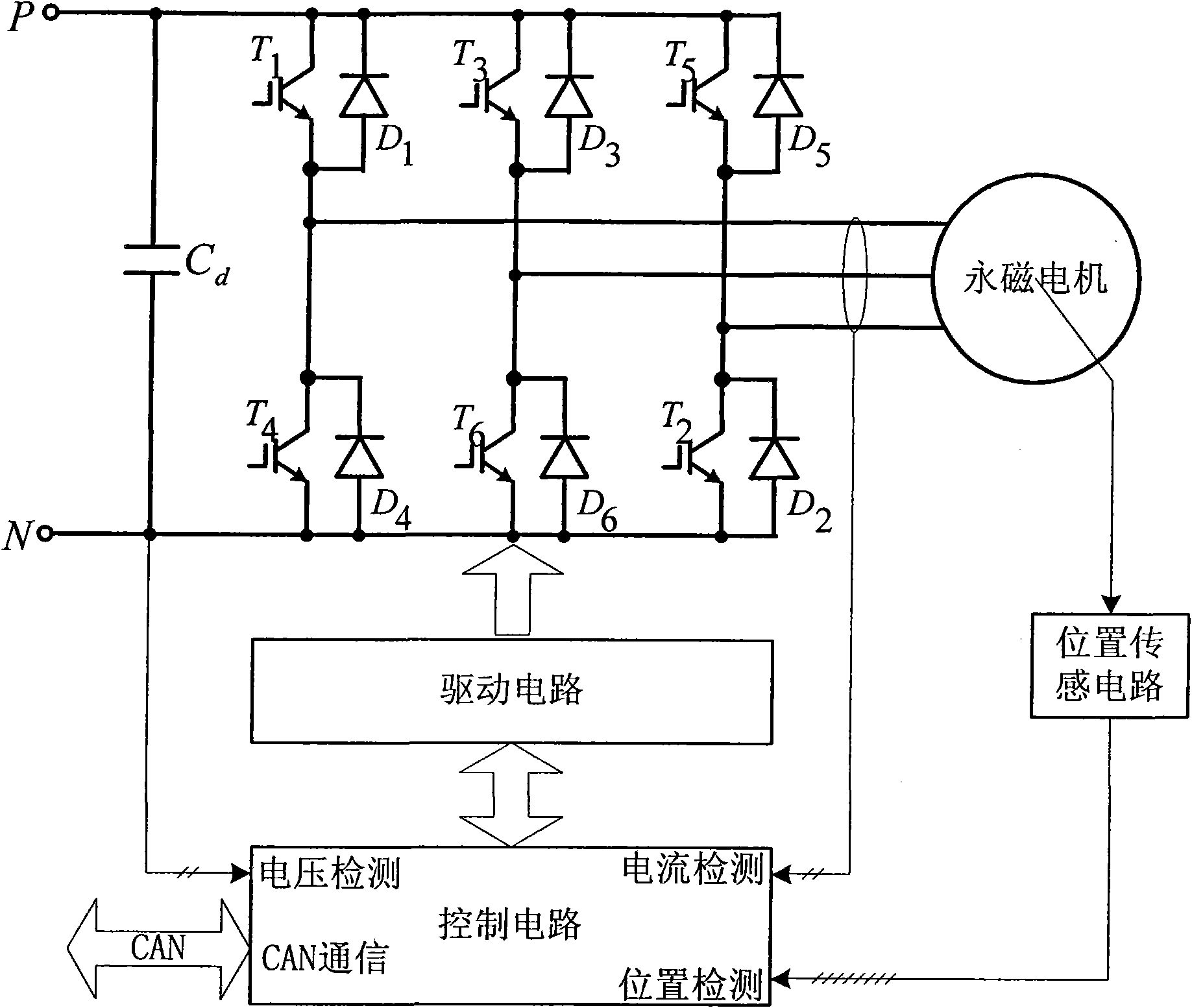

[0019] see figure 1 , the motor control system for oilfield pumping units of the present invention includes multiple permanent magnet motors M1, M2, ..., Mn, a three-phase rectifier cabinet 1, a supercapacitor 2 and multiple inverters C1, C2, ... ..., Cn. Each permanent magnet motor is respectively connected with the drive of each pumping unit and adopts vector control frequency conversion speed regulation. The three-phase rectifier cabinet 1 is externally connected to a three-phase power frequency AC power grid and outputs a DC power supply with variable voltage amplitude. The positive terminal of the DC power supply is connected to the positive terminal of the supercapacitor 2, and the negative terminal is connected to the negative terminal of the supercapacitor 2; Capacitor 2 is a 10,000-farad high-efficiency supercapacitor, which outputs a DC power supply. The positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com