Pressure-swing absorber

A technology of pressure swing adsorption and air inlet pipe, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of increasing investment costs, reducing the efficiency of adsorbents, and uneven distribution of the diameter of adsorption towers. Improve utilization efficiency, ideal treatment effect, and promote the effect of realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

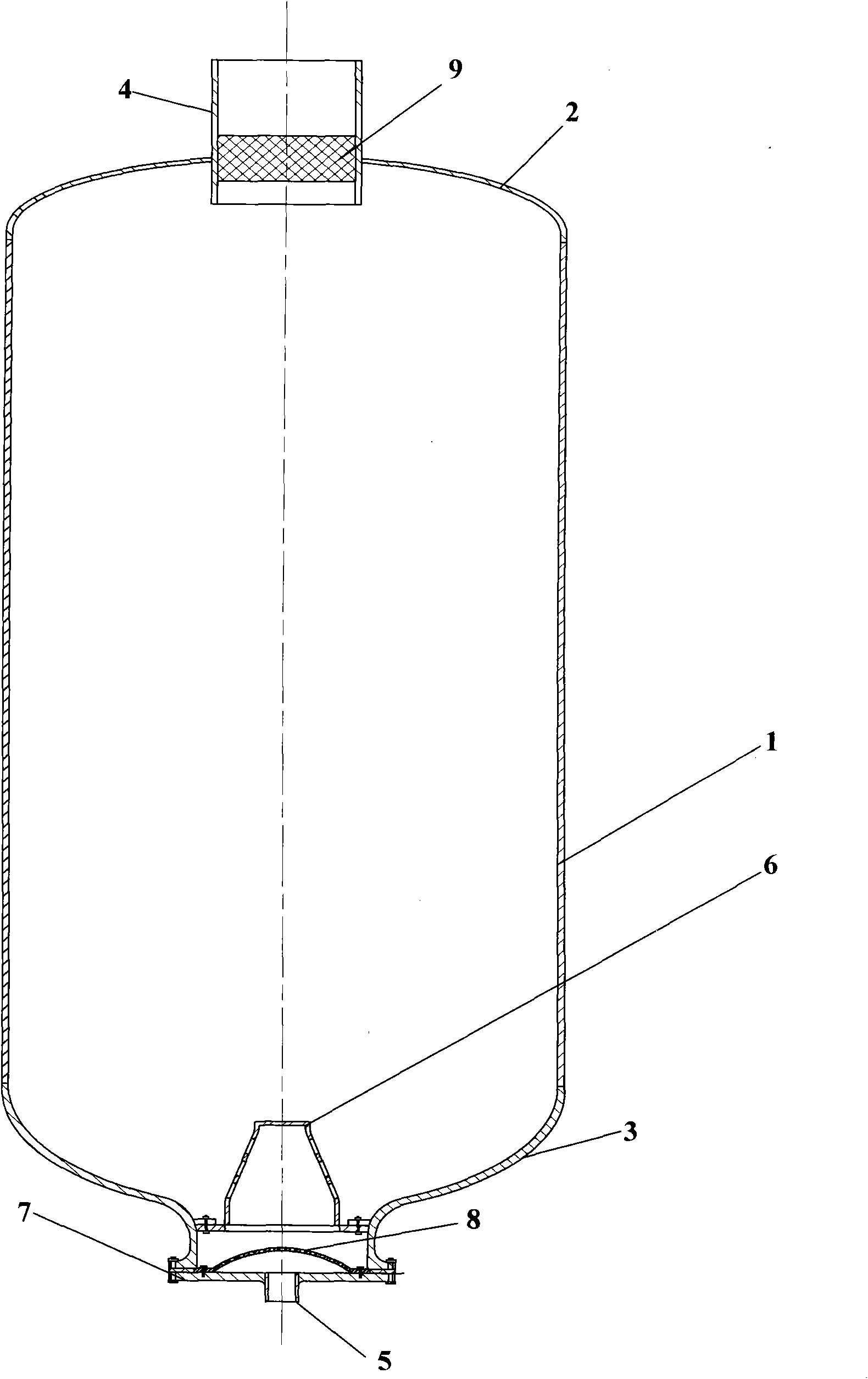

[0024] Such as figure 1 As shown, an adsorption tower includes: a cylindrical cylinder body 1, an upper head 2 and a lower head 3, an outlet pipe 4, an air inlet pipe 5, a gas distribution device 6, and an end cover 7, wherein:

[0025] The upper head 2 and the lower head 3 are respectively arranged at the two ends of the cylinder body 1 where the adsorbent is placed. side, and the end cover 7 is provided with an air inlet pipe 5, thus, the air outlet pipe 4, the upper head 2, the cylinder body 1, the lower head 3, the end cover 7 and the air inlet pipe 5 jointly form an internal cavity, only the The cavity communicates with the outside only through the outlet pipe 4 and the inlet pipe 5;

[0026] A gas distribution device 6 is arranged above the intake pipe 5. Diagrammatically, the gas distribution device 6 is fixed on the lower head 2, which is an inverted "cup"-shaped structure formed by bending a flat plate several times. Moreover, several through holes are arranged on t...

Embodiment 2

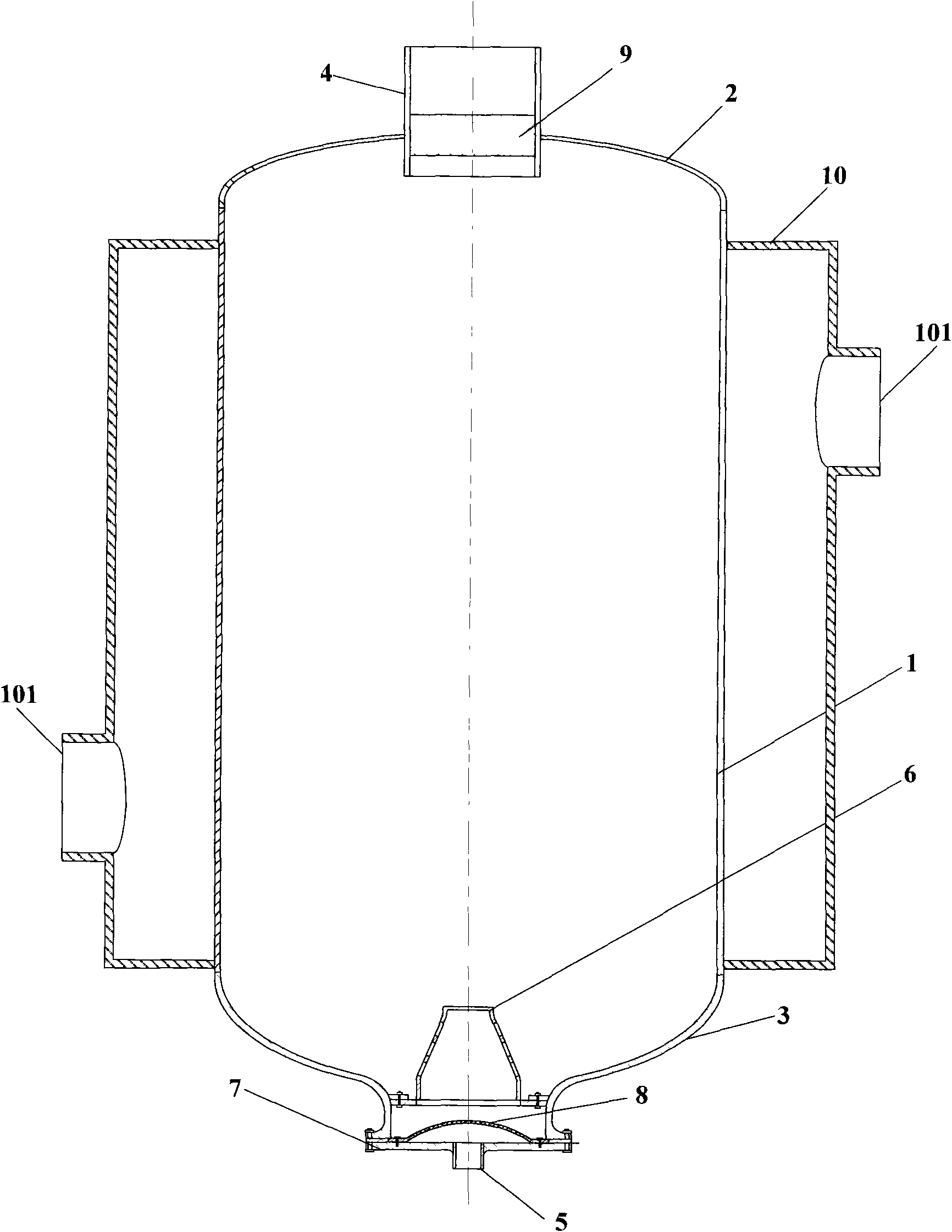

[0036] Such as figure 2 Shown is a schematic cross-sectional view of another pressure swing adsorption tower, compared with the pressure swing adsorption tower shown in Embodiment 1, a sleeve 10 is added, and the sleeve 10 is arranged on the outside of the cylinder 1, and is connected to the A hollow cavity that allows fluid flow is formed between the outer surfaces of the cylinder body 1, and the sleeve 10 can be fixed on the outside of the cylinder body 1 by direct welding, or can be fixed on the outside of the cylinder body 1 through internal connecting ribs (not shown). The connection is fixed. Moreover, the sleeve 10 is provided with two connection nozzles 101 communicating with the outside.

[0037] During the actual use of the pressure swing adsorption tower, a heat exchange fluid is introduced from a connecting nozzle 101, and the fluid exchanges heat with the cylinder body 1 in the hollow cavity formed between the sleeve 10 and the cylinder body 1, thereby To affec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com