Microscopic bubble or drop generating device

A device for generating micro-bubbles, applied in the direction of dissolution, mixers, chemical instruments and methods, etc., can solve problems such as limited application range, complex structure, etc., achieve broad market prospects, stable and reliable operation, and solve micro-bubbles or droplets The effect of the need problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

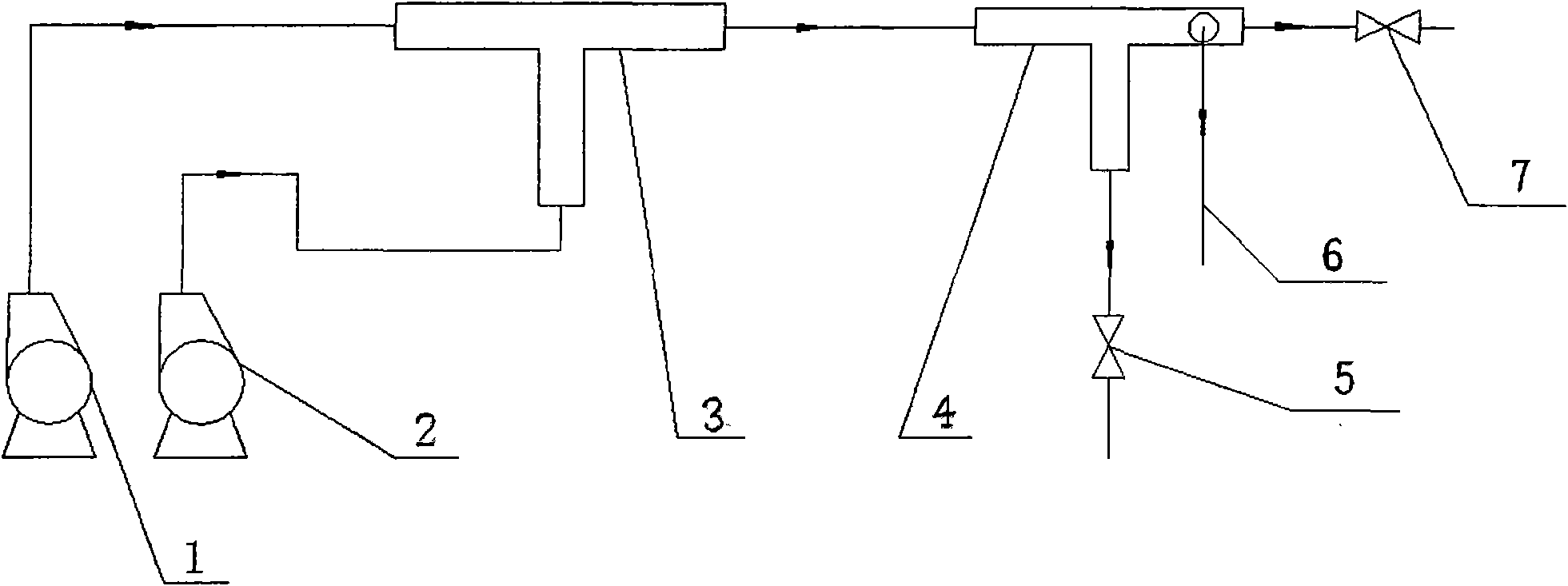

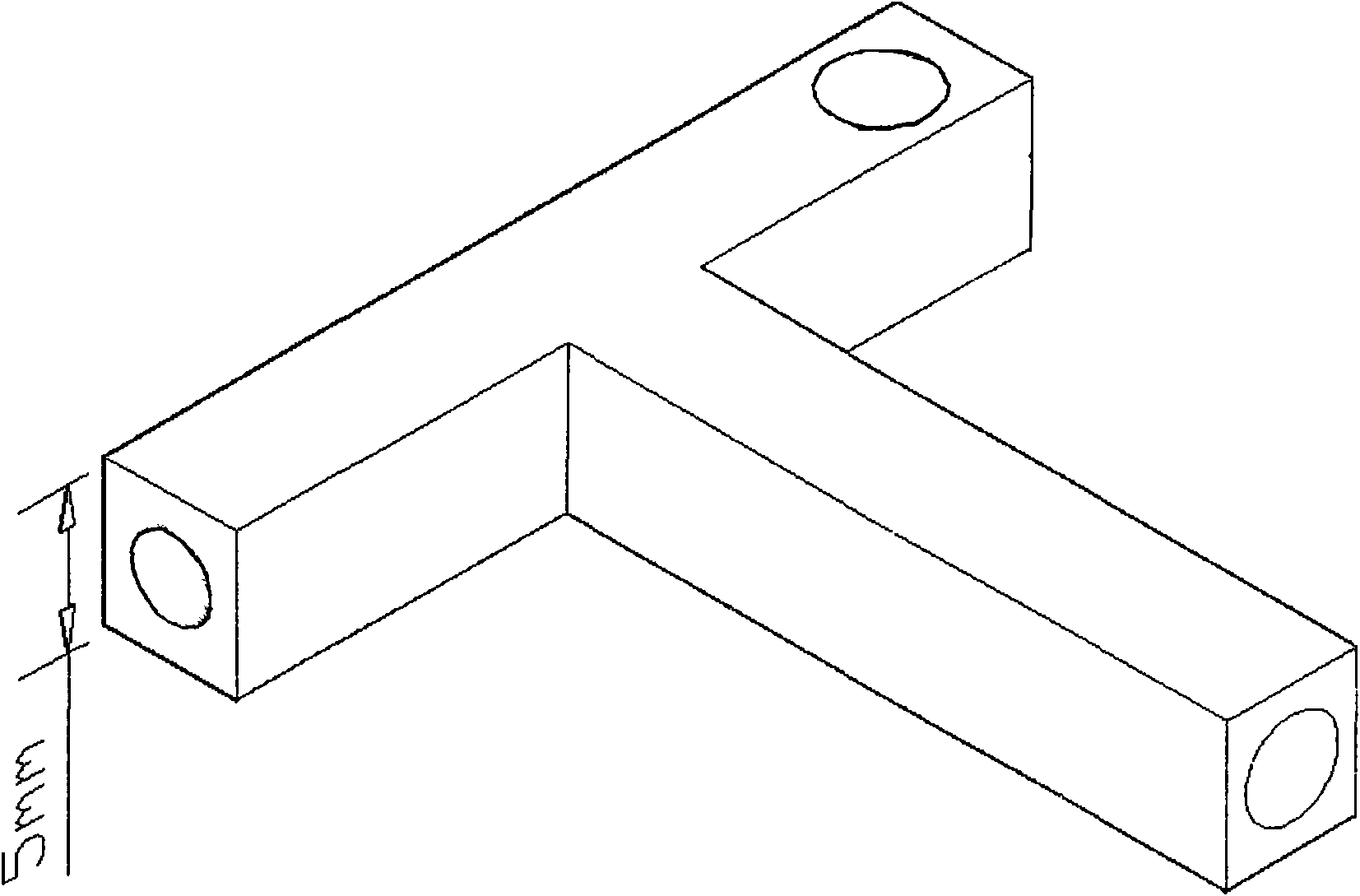

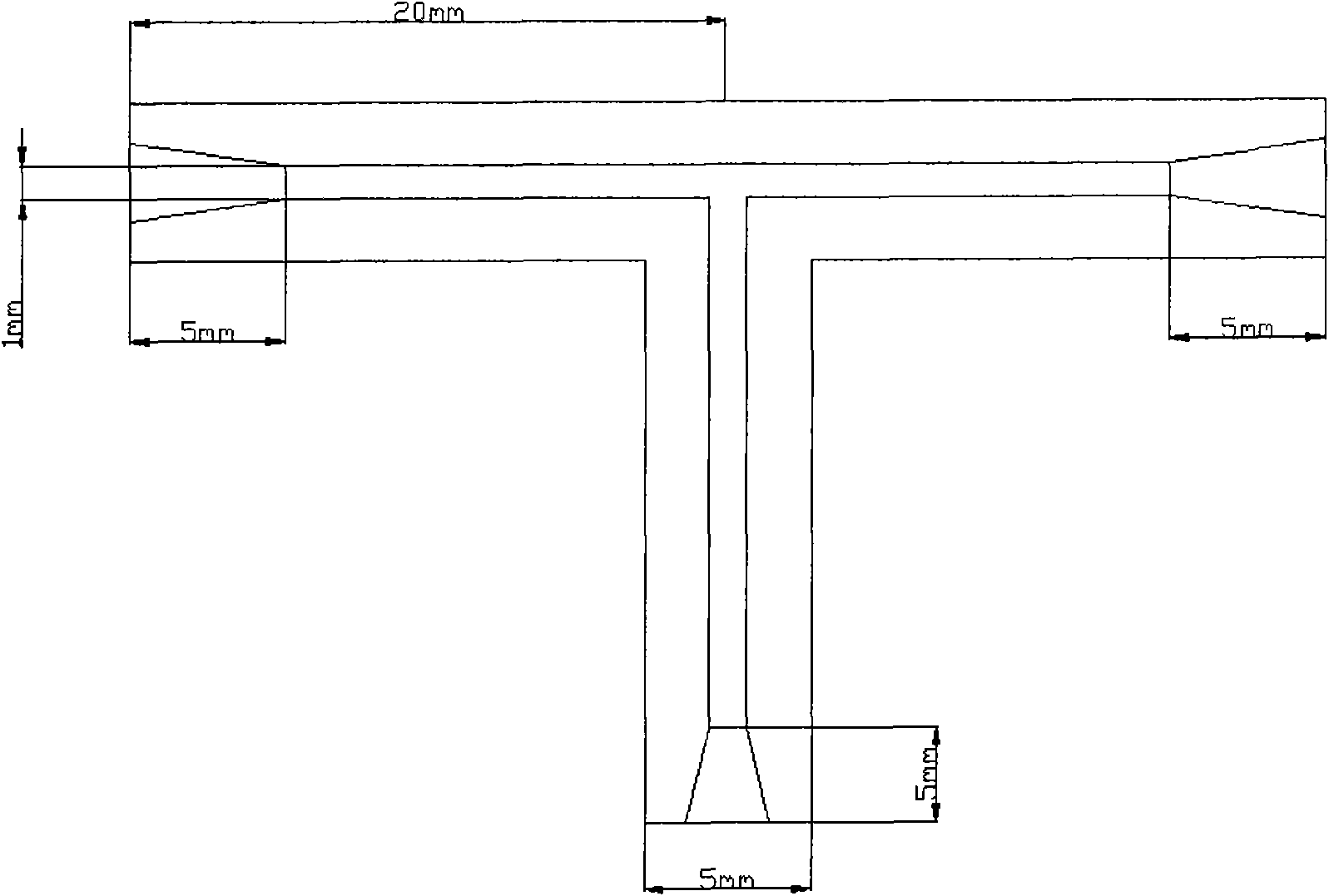

[0029] Figure 5 It is the bubble diameter distribution diagram obtained by experimenting with air and water as the main phase and dispersed phase respectively. Implementation conditions: if figure 1 In the device shown, the main phase delivery pump 1 is a WZ-50C66T syringe pump from Zhejiang University Medical Instrument Company; the dispersed phase delivery pump 2 is a 40L steel cylinder and a hot gas mass flow controller (Dongguan Dexin Electronic Technology Co., Ltd. Company DSN-S); mixing T-type tee 3 inner diameter is 1mm; distribution T-type tee 4 inner diameter is 0.5mm; first micro valve 5 and second micro valve 7 are SS-723K2 produced by Xiongchuan Valve; outlet pipe 6 The diameter is 3mm. The main phase is water at normal temperature and pressure; the dispersed phase is air at normal temperature and pressure.

[0030]First, the flow ratio of the main phase and the dispersed phase was determined to be 1:10. Then fix the opening of the side branch valve (the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com