Mirror grinding material and preparation method thereof

A technology of mirror surface grinding and abrasive materials, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of residue splashing, strong acid gas in the production site, environmental pollution, etc., and achieve the effect of clear mirror surface and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The components (weight %) of each embodiment are listed as follows:

[0017] Component

(weight %)

AL 2 o 3

HNO 3

h 2 o

Example 1

0.06

0.45

99.49

Example 2

0.08

0.60

99.32

Example 3

0.09

0.65

99.26

Example 4

0.10

0.80

99.10

Example 5

0.13

0.85

99.02

Example 6

0.16

1.60

98.24

Example 7

0.28

8.43

91.29

Example 8

0.25

8.30

91.45

Example 9

0.18

12.14

87.68

Example 10

0.23

8.46

91.31

Example 11

0.14

7.86

92.00

Example 12

0.29

8.50

91.21

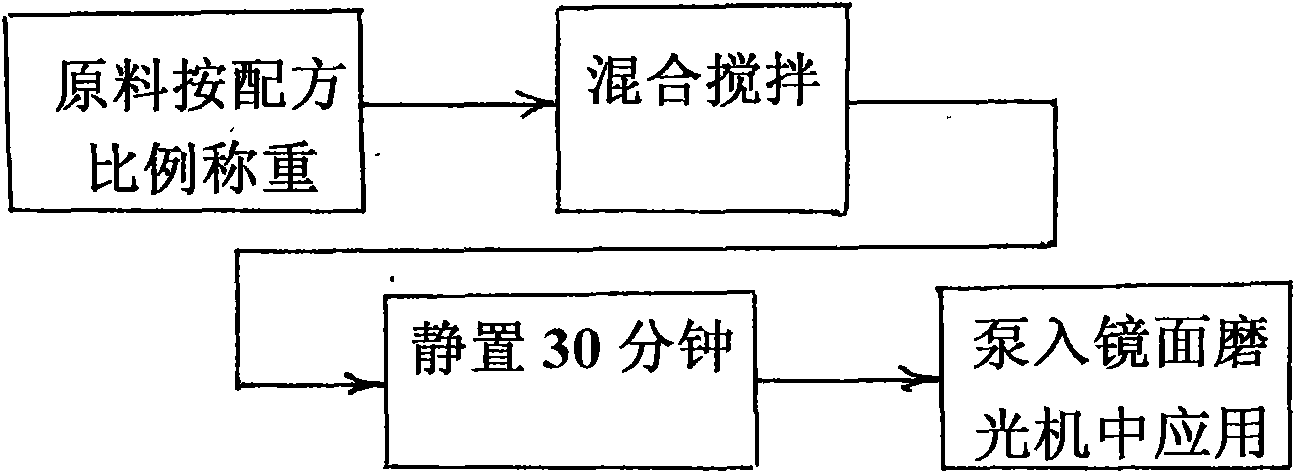

[0018] Fully mix and stir the raw materials of the above-mentioned components, and after standing for 30 minutes, pump them into a mirror grinder for application.

[0019] Among the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com