Ceramic/composite material interlayer protecting structure

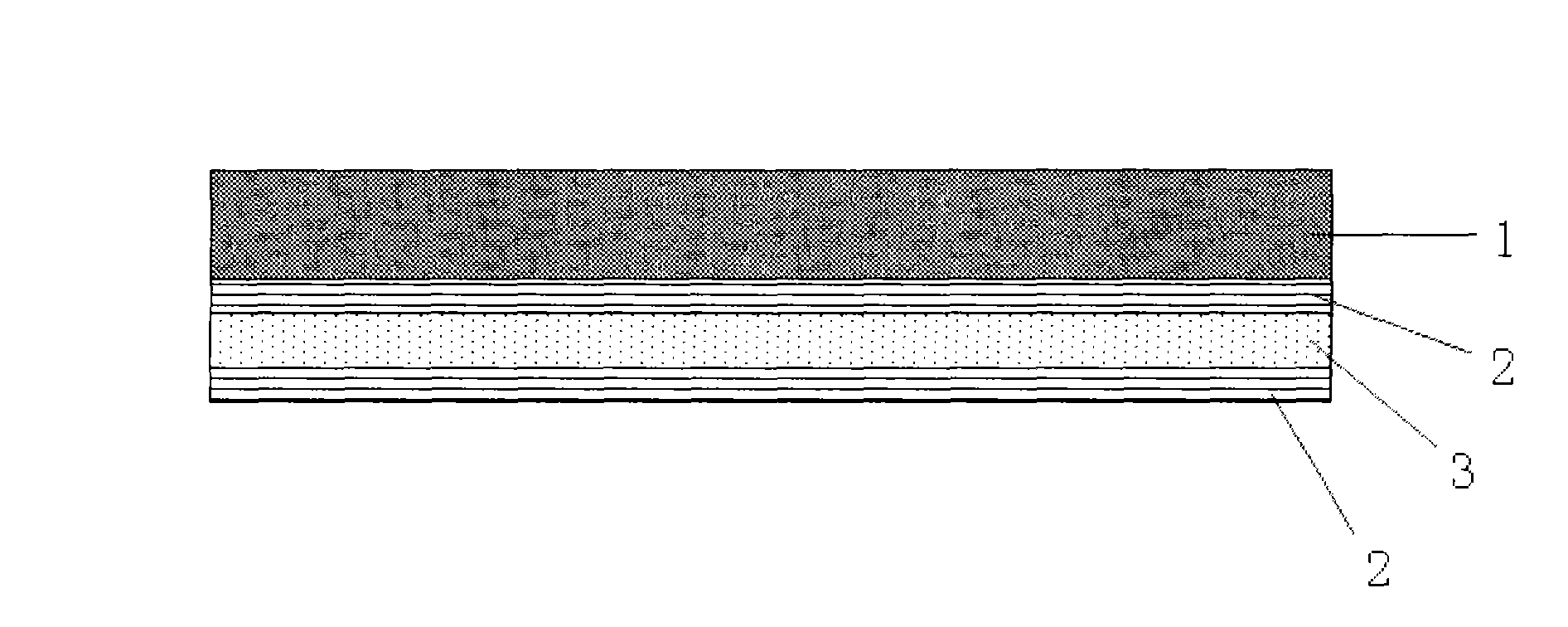

A technology of protective structure and composite material, applied in ceramic layered products, armor plate structure, synthetic resin layered products, etc., can solve the problems of reducing the protection coefficient of the protective structure, increasing the surface density of the overall protective structure, etc., so as to improve the ballistic trajectory. Ultimate speed, areal density reduction, effects of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to the concept of the present invention, the thickness of the panel is 8mm, the material is hot-pressed sintered boron carbide, the thickness of the composite material plate is 5mm, the material is aramid fiber composite material, the thickness of the aluminum foam core is 6mm, the aperture is 4mm, and the porosity is 90%. The impact test shows that the structure can resist the penetration of 12.7mm caliber steel core warheads. Compared with the existing ceramic / composite material structure, the surface density of the protection structure prepared by the invention is reduced by 14% under the same protection level.

Embodiment 2

[0020] According to the concept of the present invention, the thickness of the panel is 10mm, the material is hot-pressed sintered alumina, the thickness of the composite material plate is 5mm, the material is glass fiber composite material, the thickness of the aluminum foam core is 6mm, the aperture is 4mm, and the porosity is 80%. The impact test shows that the structure can resist the penetration of 12.7mm caliber steel core warheads. Compared with the existing ceramic / composite material structure, the surface density of the protection structure prepared by the invention is reduced by 10% under the same protection level.

Embodiment 3

[0022] According to the concept of the present invention, the thickness of the panel is 5mm, the material is hot-pressed sintered boron carbide, the thickness of the composite material plate is 3mm, the material is aramid fiber composite material, the thickness of the aluminum foam core is 4mm, the aperture is 2mm, and the porosity is 80%. The projectile test shows that the structure can resist the penetration of 7.62mm caliber steel core warhead. Compared with the existing ceramic / composite material structure, the surface density of the protection structure prepared by the invention is reduced by 12% under the same protection level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com