Device and method for measuring geometric parameter of superplastic non-spherical free bulge

A technology of geometric parameters and measurement methods, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large space occupation, random errors in artificial measurement, high equipment cost, etc., and achieve fast speed, high measurement accuracy, and non-contact The effect of getting information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific content and usage method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

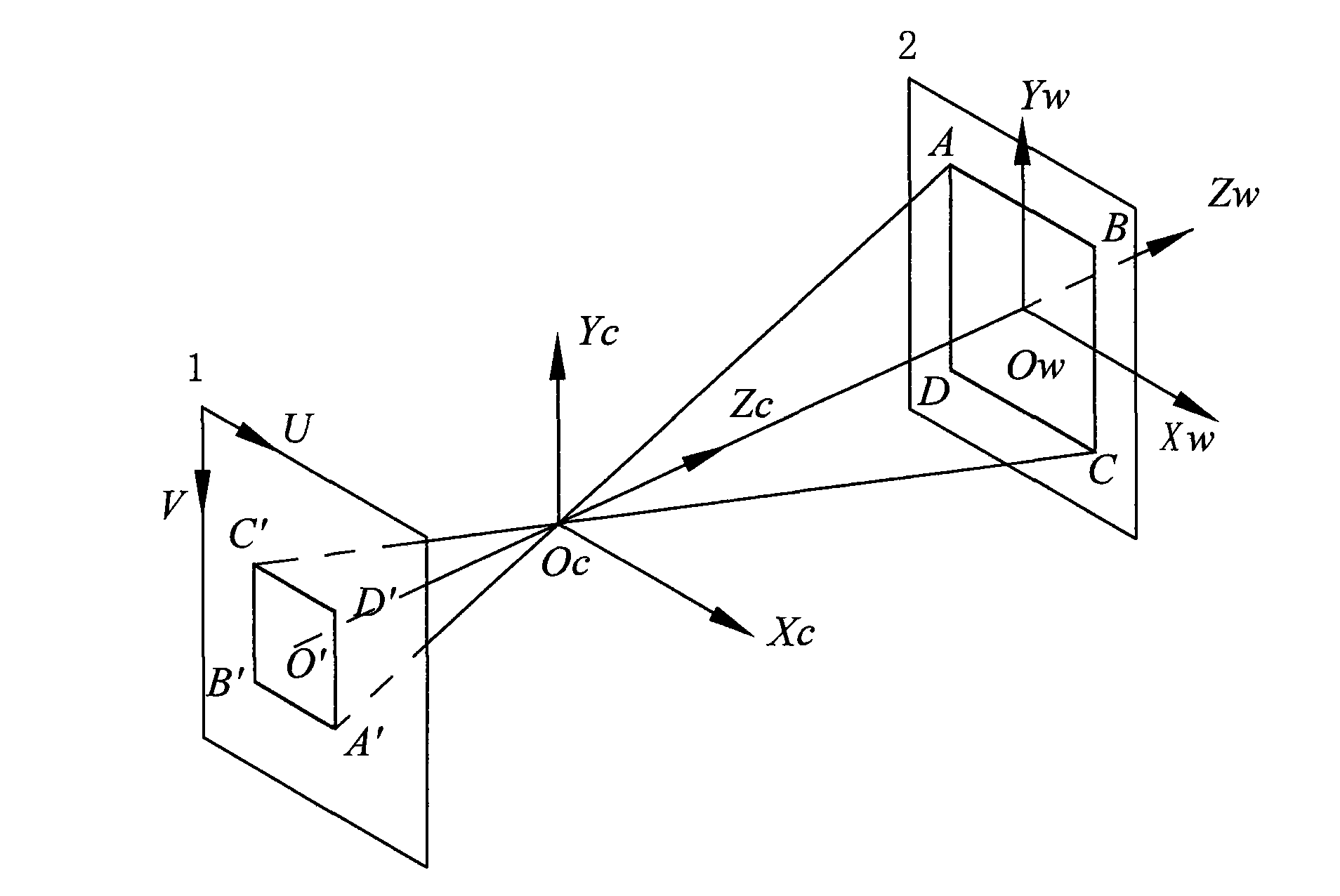

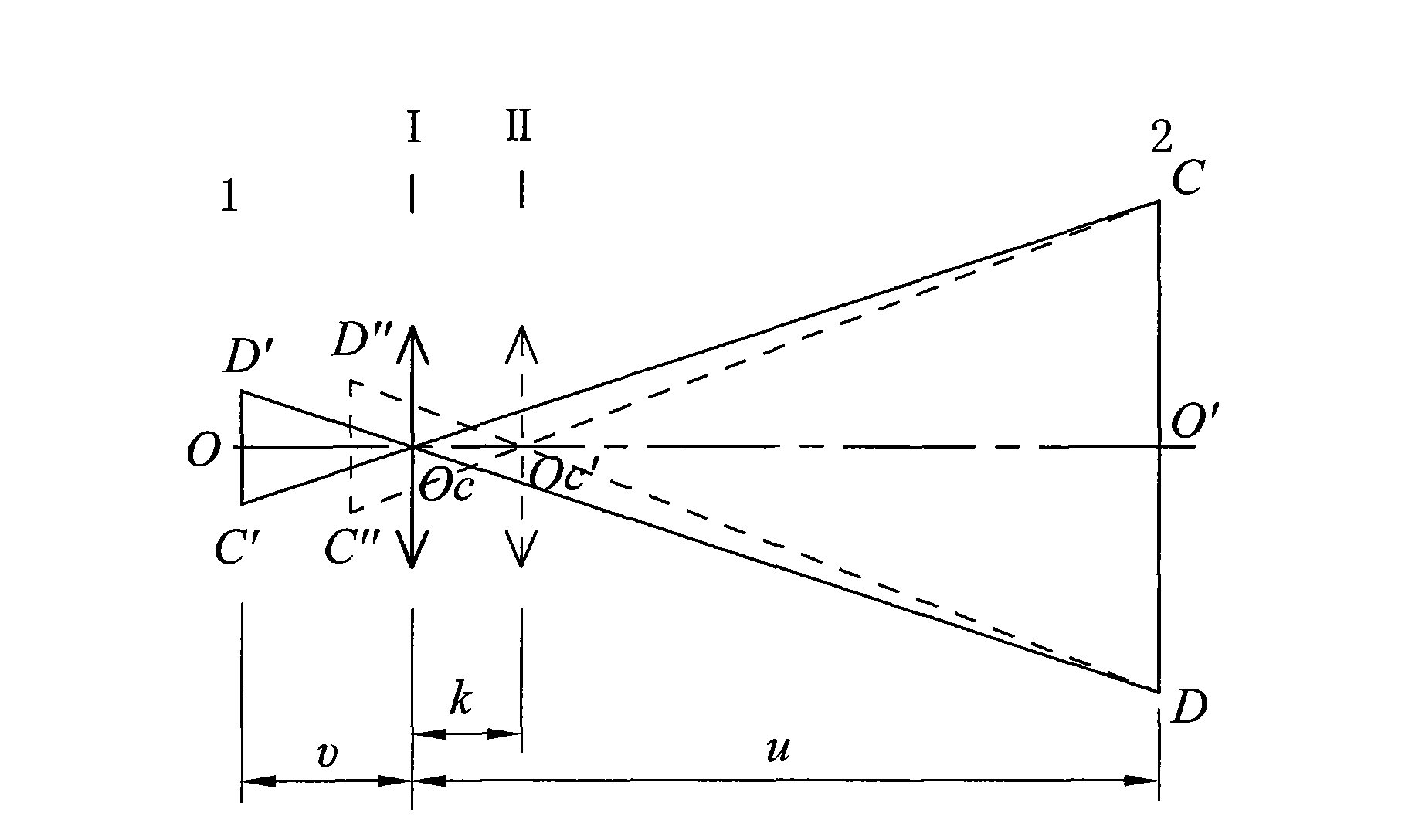

[0034] Take the measurement of a bulge whose shape is an axisymmetric surface of revolution as an example, such as Figure 4 As shown, the measurement content of its geometric parameters mainly measures the coordinates of each point on the contour curve of the bulging part in the figure, so that the equation of the contour curve can be fitted, and the latitudinal curvature radius ρ of each point on the surface can be further solved θ and the meridional radius of curvature ρ s .

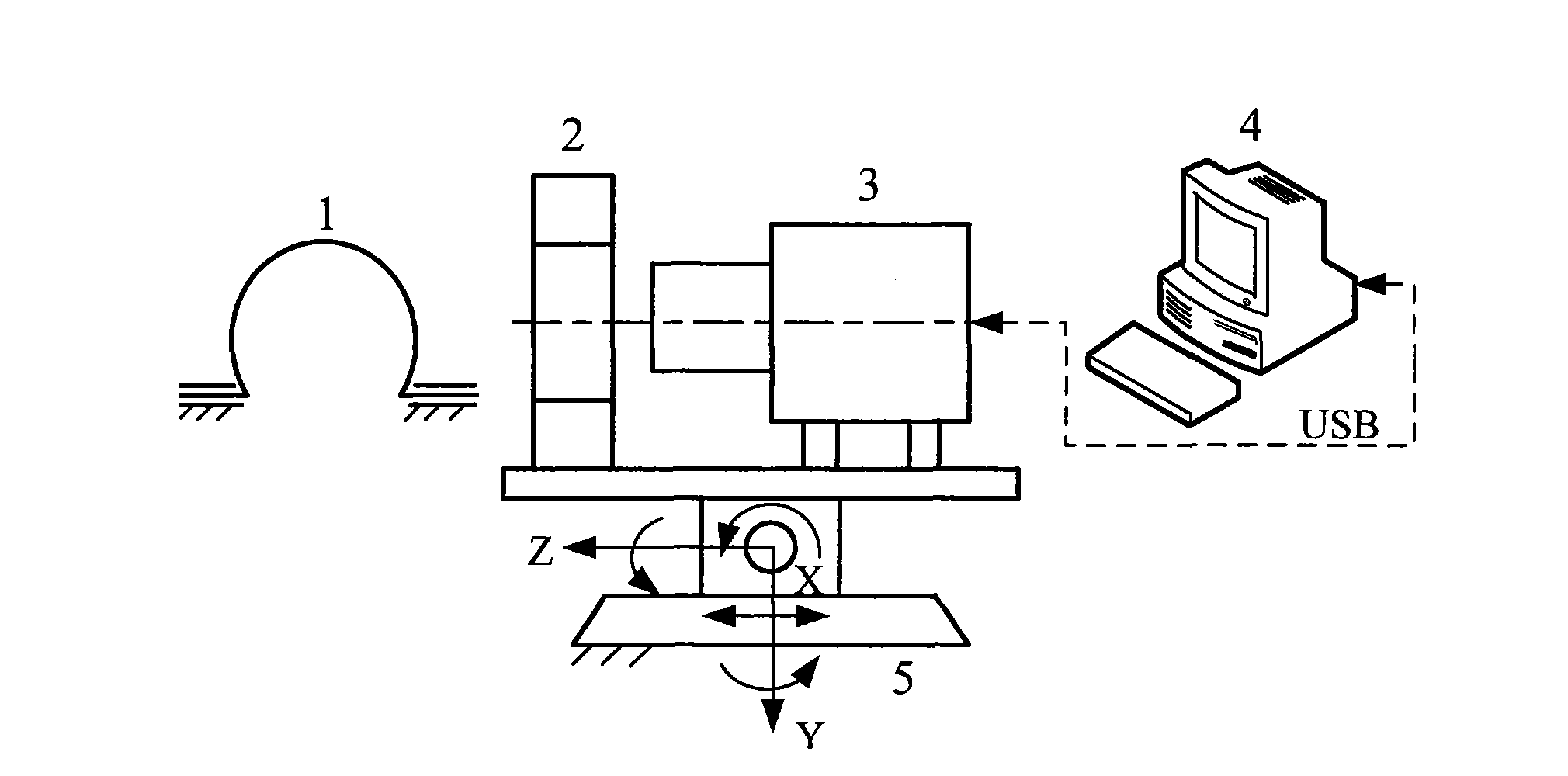

[0035] figure 1 The composition diagram of the whole measurement device is given, which is composed of the measured bulge, ring light source, camera, PC and adjustable pan / tilt.

[0036] Among them, the choice of digital camera can be selected according to the size range and measurement accuracy requirements of the tested piece. Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com