Roller gap measuring and regulating method of four-roller paint applicator

A roll gap and paint machine technology, applied in coating, measuring device, device for coating liquid on the surface, etc., can solve the problems of increasing signal contrast, uncertainty of measurement accuracy, difficulty and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

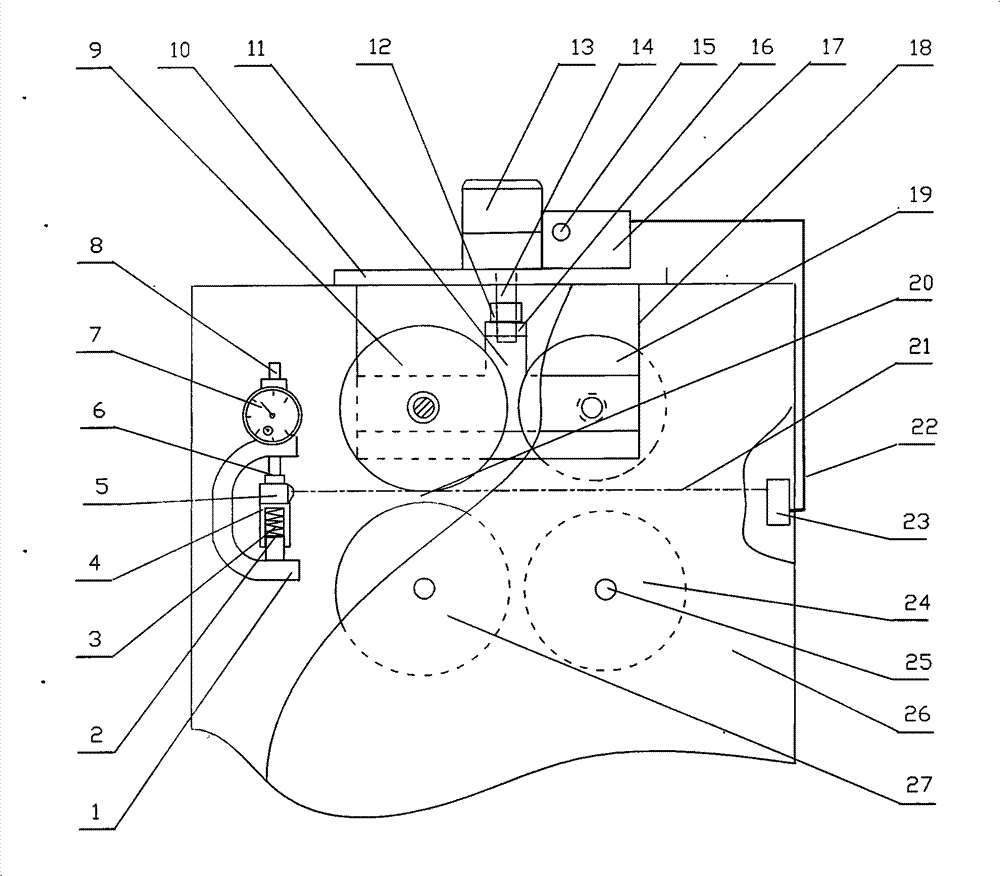

[0008] In the figure, 1 is the micrometer support, 2 is the static end of the measuring part, 3 is the compression spring, 4 is the limiting sleeve, 5 is the beam laser generator, 6 is the dynamic end of the measuring part, 7 is the dial, 8 is Adjusting knob, 9 is the upper rubber roller, 10 is the shelf, 11 is the sliding block, 12 is the nut, 13 is the stepping motor with reducer, 14 is the output shaft connecting screw, 15 is the indicator light, and 16 is the sliding block Connecting board, 17 is the electrical control box, 18 is the sliding block slot, 19 is the upper auxiliary roller, 20 is the nip, 21 is the beam line, 22 is the signal line, 23 is the photoelectric receiving converter, 24 is the lower auxiliary roller, 25 Is the shaft head, 26 is the wallboard, and 27 is the lower rubber roller. The above micrometer holder 1, the dial 7 and the adjusting knob 8 form a micrometer card. The components of the four-roller paint machine are the same as those of the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com