Micro phase delay measuring device for optical element based on laser feedback

A technology of laser feedback and optical components, which is applied in the field of laser measurement, can solve the problems of multi-instrument error and azimuth adjustment error, increase the complexity of the measurement system, and limit the measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

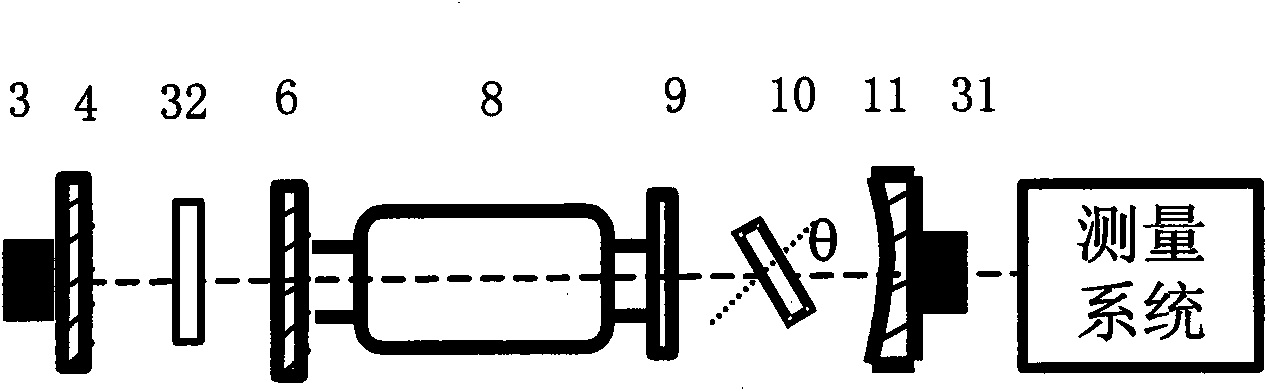

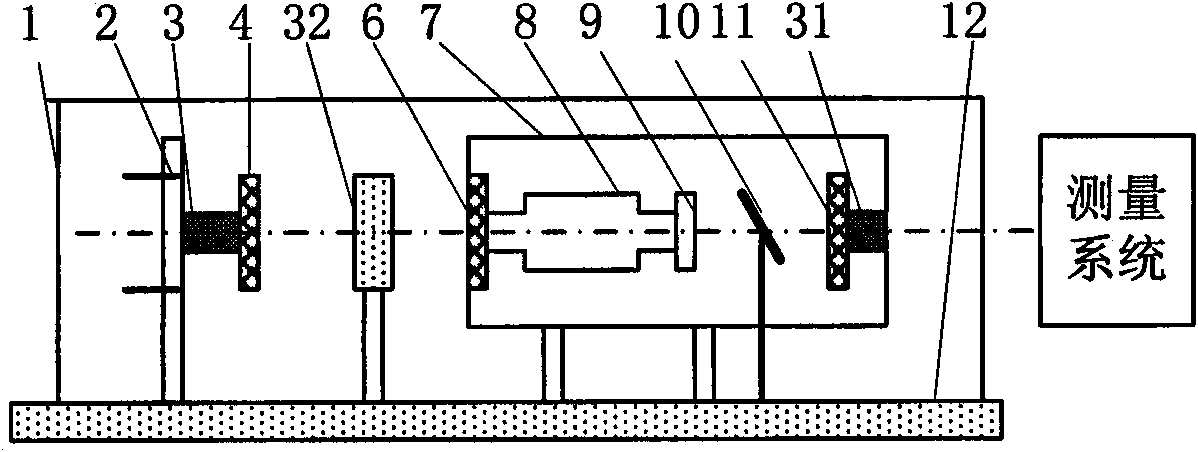

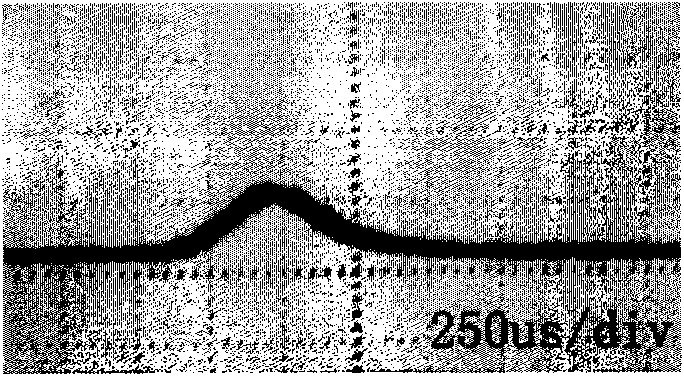

[0045] Example: such as figure 1 or figure 2 In the experimental system of the quarter-wave plate feedback, when the external cavity length changes, the two eigenpolarization states of the laser mode will alternately oscillate in two orthogonal directions, and the external cavity length changes for every λ / 4. The polarization state jumps once, and the two polarization states have the same duration within one laser intensity modulation period. When the feedback mirror 4 moves left and right along the laser axis under the impetus of the piezoelectric ceramic 3, the change frequency of the scanning voltage applied to the piezoelectric ceramic 3 can be adjusted so that the polarization state of the laser jumps once every 10 ms or so, so that The measurement of the frequency difference can be realized by scanning the interferometer so that two alternately oscillating polarization modes are simultaneously displayed on the oscilloscope.

[0046] First, observe the laser mode with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com