Preparation method for zirconium-based amorphous alloy

A zirconium-based amorphous alloy and a zirconium-based technology are applied in the field of preparation of zirconium-based amorphous alloys, which can solve problems such as three-dimensional size limitation, and achieve the effects of improving the forming ability, reducing the nucleation rate and high forming ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

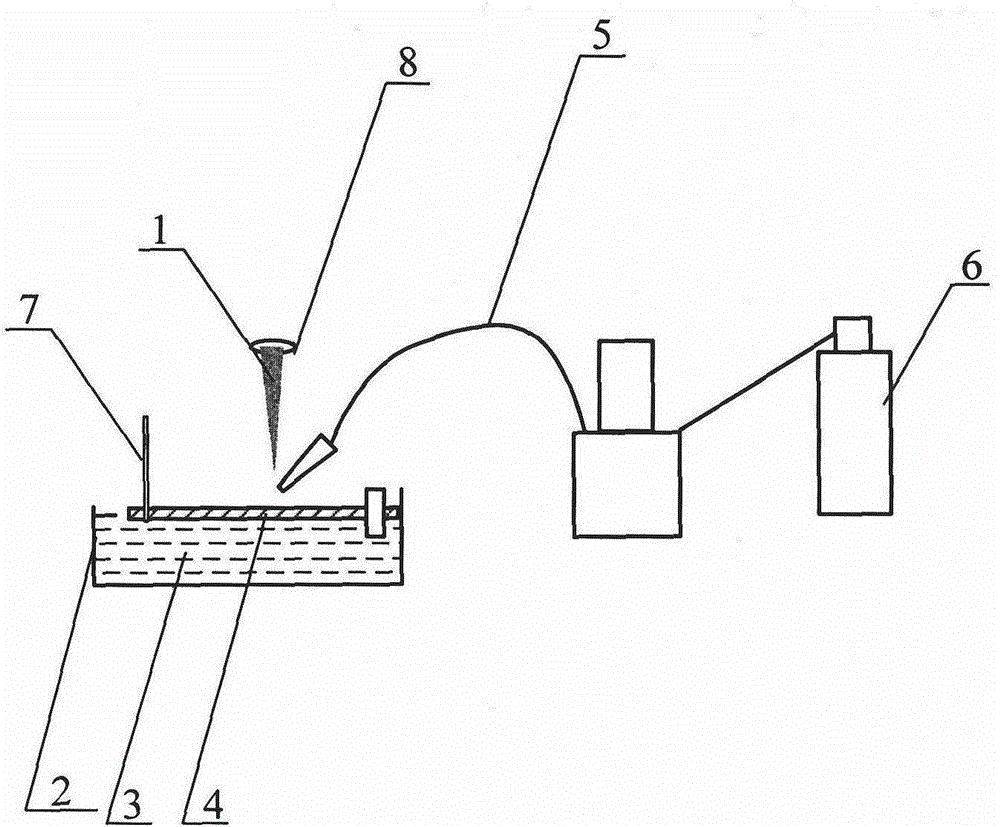

[0030] The invention provides a method for preparing a zirconium-based amorphous alloy, which specifically comprises the following steps:

[0031] 1), one end of the base material is fixedly connected to the side wall of the reactor, the other end is rotatably suspended in the reactor, and a cooling medium is passed into the reactor until at least 1 / 3 of the base material the cross section is immersed in said cooling medium;

[0032] 2), the zirconium-based mixed fine powder is fed to the upper surface of the base material at a uniform speed by the powder feeding control device, and is located directly below the laser processing head; the zirconium-based mixed fine powder includes a mass ratio of (580~ 585): (30-31): (100-102): (48-49) zirconium fine powder, aluminum fine powder, nickel fine powder and copper fine powder; the particle size of the zirconium-based mixed fine powder is 300 mesh ~500 mesh;

[0033] 3) Turn on the laser, the laser processing head is connected wit...

Embodiment 1

[0058] Step 1): surface pretreatment of carbon steel rod 4:

[0059] ① The upper surface of the carbon steel rod 4 is roughened by sandblasting with a sandblasting machine, and the surface roughness of the obtained upper surface is Ra2.5 μm. The purpose of this operation is to degrease and deoxidize the upper surface of the carbon steel rod 4 Membrane grinding and cleaning;

[0060] ②Clean the upper surface with a cleaning solvent, dry the upper surface naturally, and use it as a working surface;

[0061] Step 2): Pretreatment of zirconium-based mixed powder:

[0062] ① Grind zirconium powder, aluminum powder, nickel powder and copper powder respectively, and pass through a 200-mesh sieve to obtain fine powder, which are respectively zirconium fine powder, aluminum fine powder, nickel fine powder and copper fine powder, and the particle diameter of the obtained fine powder is ≤0.075 mm;

[0063] 2. Put the zirconium fine powder, aluminum fine powder, nickel fine powder and ...

Embodiment 2

[0078] Step 1): surface pretreatment of carbon steel rod 4:

[0079] ① The upper surface of the carbon steel rod 4 is roughened by sandblasting with a sandblasting machine, and the surface roughness of the obtained upper surface is Ra5.0 μm.

[0080] ②Clean the upper surface with a cleaning solvent, dry the upper surface naturally, and use it as a working surface;

[0081] Step 2): Pretreatment of zirconium-based mixed powder:

[0082] ① Grind zirconium powder, aluminum powder, nickel powder and copper powder respectively, and pass through a 150-mesh sieve to obtain fine powder, which are respectively zirconium fine powder, aluminum fine powder, nickel fine powder and copper fine powder, and the particle diameter of the obtained fine powder is ≤0.1 mm;

[0083] ②The zirconium fine powder, aluminum fine powder, nickel fine powder and copper fine powder obtained in step 2) ① are mixed in a container in a mass ratio of 580:30:102:48, and stirred evenly to obtain a mixed fine po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com