Scraper blade surface detection system

A scraper blade and surface cleaning technology, applied in the field of light detection, can solve the problems of slow moving scraper blade, visual fatigue, slow detection speed, etc., and achieve the effect of high brightness of diffuse reflection light, large illumination range, and fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

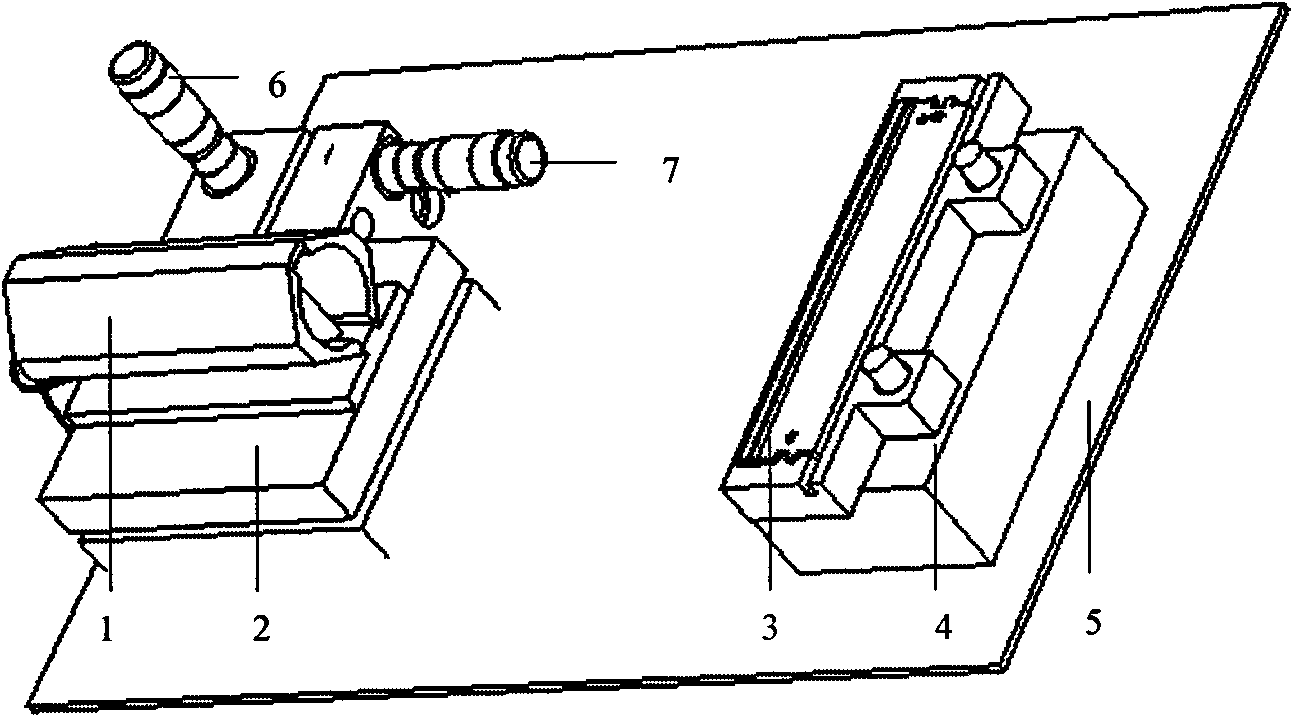

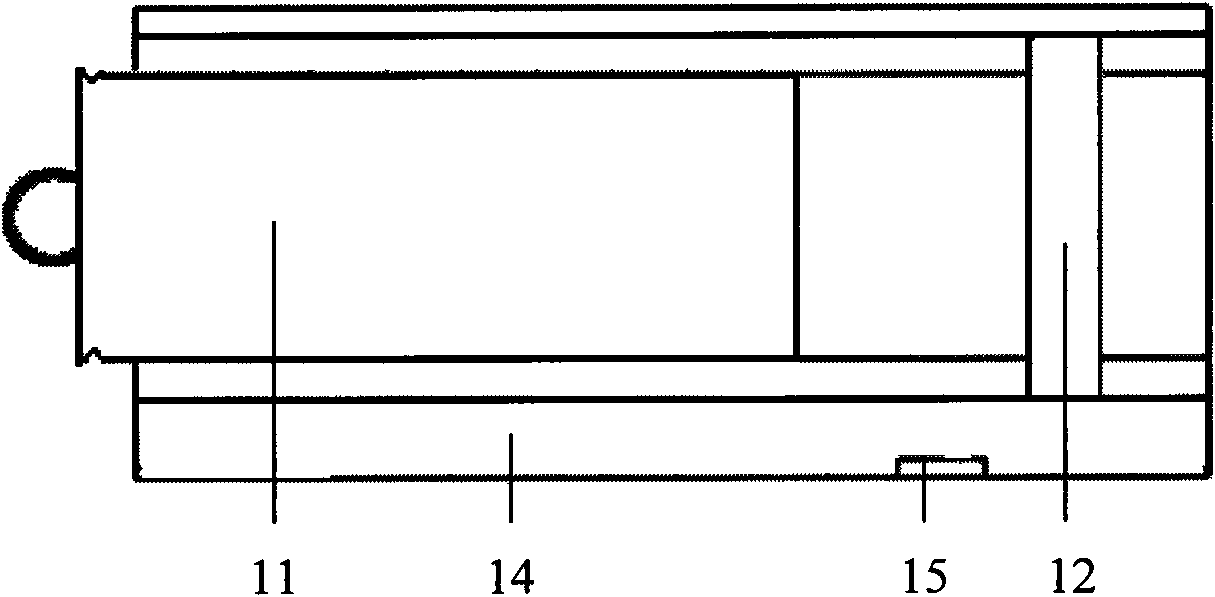

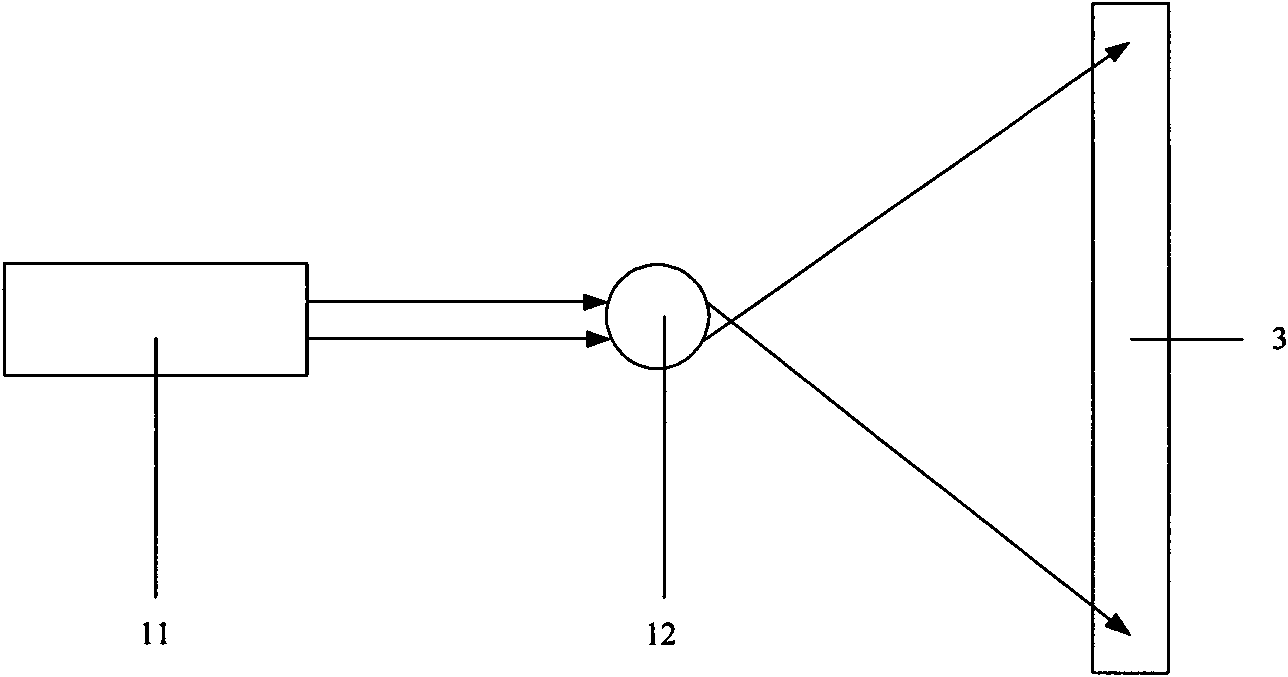

[0018] The doctor blade surface detection system is a non-destructive optical detection device. First place the scraper blade 3 on the stage 4, put the semiconductor laser 11 and the shaping lens 12 into the cylindrical cylinder 13 in turn, the sagittal direction of the shaping lens 12 is parallel to the base of the cylinder, and place the laser unit 1 in a three-dimensional Adjust the platform 2 and adjust the general direction, then turn on the semiconductor laser 11, and the emitted laser beam is passed through the shaping lens 12 to obtain a fan-shaped laser beam, such as image 3 shown. Adjusting the vertical knob 6 and the horizontal knob 7 on the three-dimensional platform 2 can project the fan-shaped laser beam onto the entire surface of the doctor blade 3 . The surface of good quality scraper blade is mirror surface without diffuse reflection effect, such as Figure 5 As shown, when the laser beam hits the scraper blade 3, no bright reflection line can be seen along...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com