Class-155 acetal flat enamelled copper wire and method of producing same

A production method and technology of acetal paint, applied in flat/ribbon cables, organic insulators, insulation of conductors/cables, etc., can solve the problems of bird skin, low temperature resistance level, and easy to generate burrs, etc., to improve the temperature level , high temperature resistance level, the effect of avoiding burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

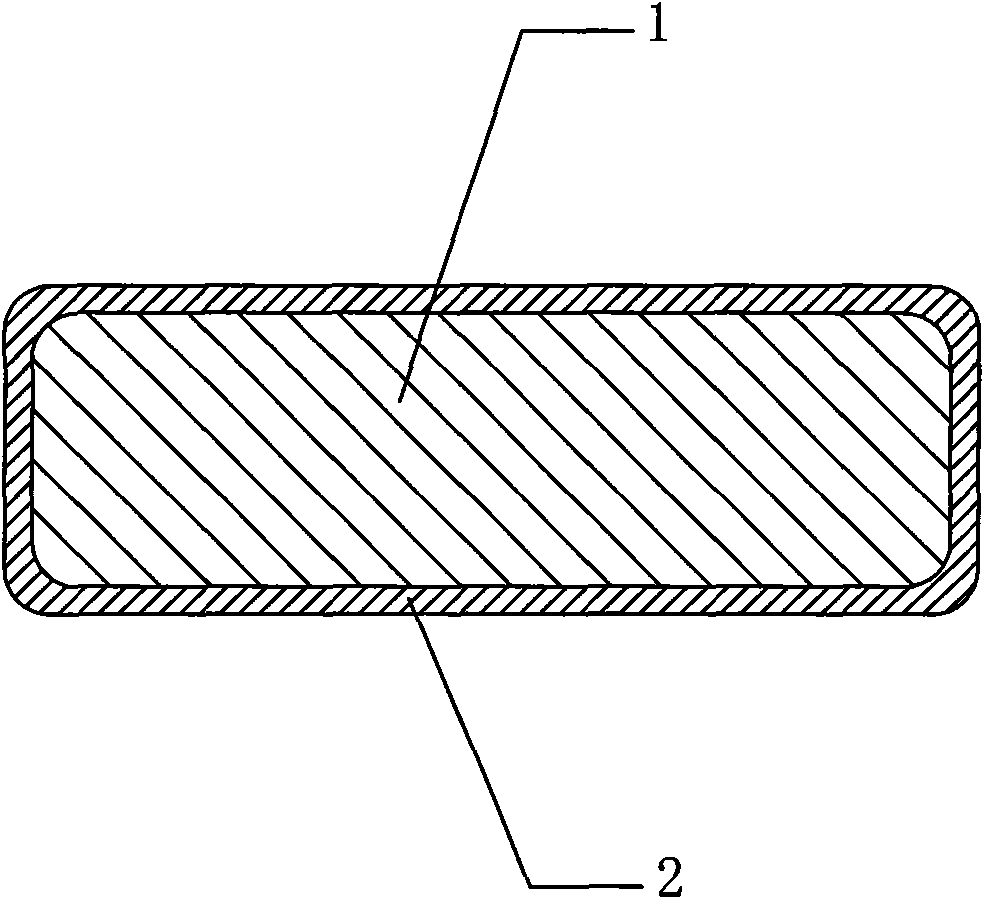

[0010] See figure 1 , the 155-grade acetal enamelled copper flat wire of the present invention includes a metal copper conductor 1, and the metal copper conductor is coated with an insulating varnish 2 outside, and the insulating varnish 2 is a modified polyvinyl acetal resin, which has a high solid content and a high viscosity , can reduce the number of paint coats, improve production efficiency, and achieve the purpose of reducing energy consumption and saving costs.

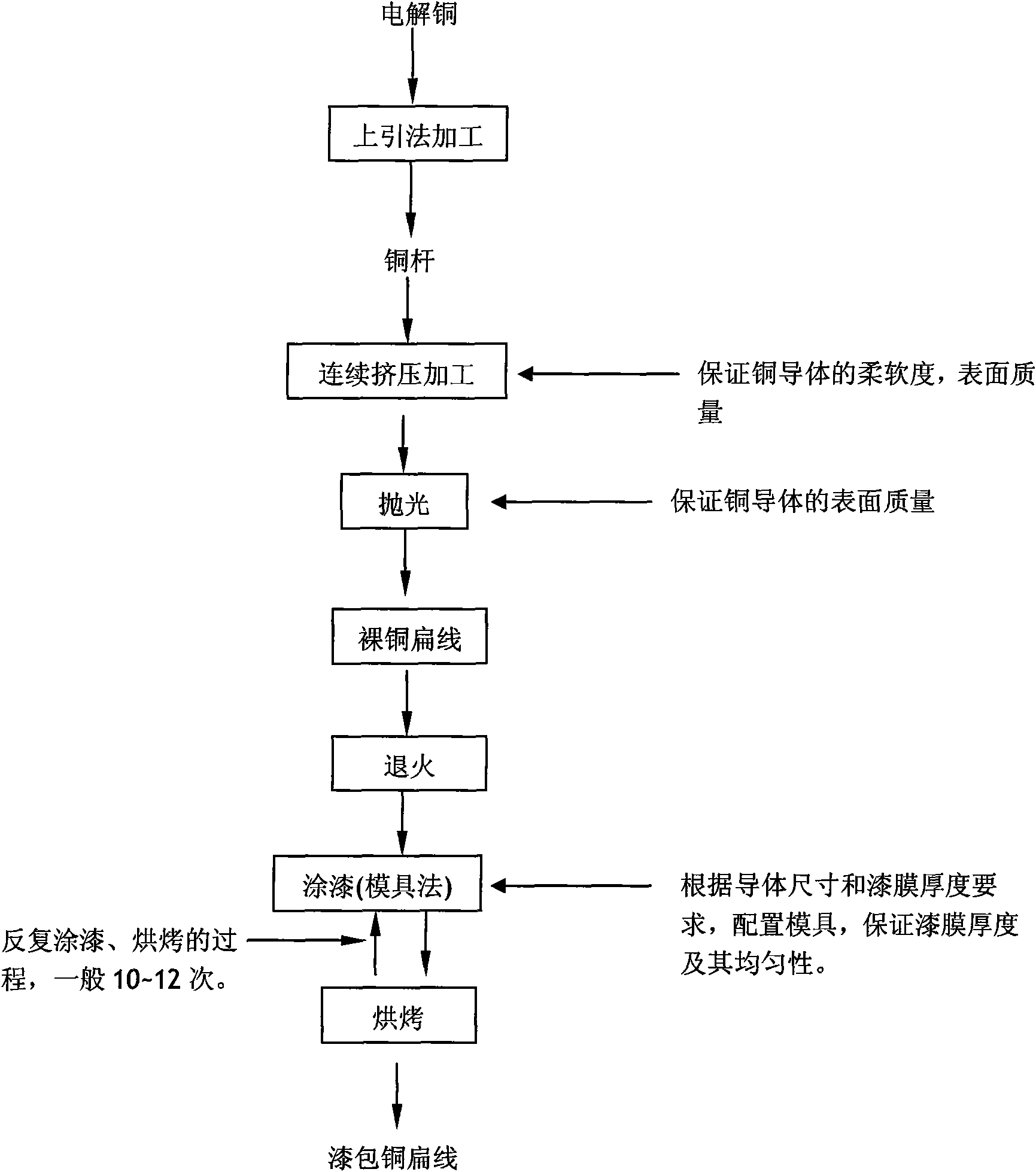

[0011] See figure 2 , the production process of the 155-grade acetal enamelled copper flat wire of the present invention is described in detail below: the electrolytic copper raw material is processed by the up-drawing method to produce an oxygen-free copper rod, and then the oxygen-free copper rod is processed and polished by a continuous extrusion machine into a bare copper flat wire, and annealed with water vapor protection, then painted, and finally baked. Among them, the bare copper flat wire is produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com