Wire and foil mixedly winding coil grounding transformer

A technology for grounding transformers and coils, used in coil manufacturing, transformer/inductor coils/windings/connections, etc., can solve the problems of uneven distribution of capacitance and weak lightning shock resistance, achieve uniform potential distribution, and improve lightning shock resistance. The effect of strength, lightning shock resistance and electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

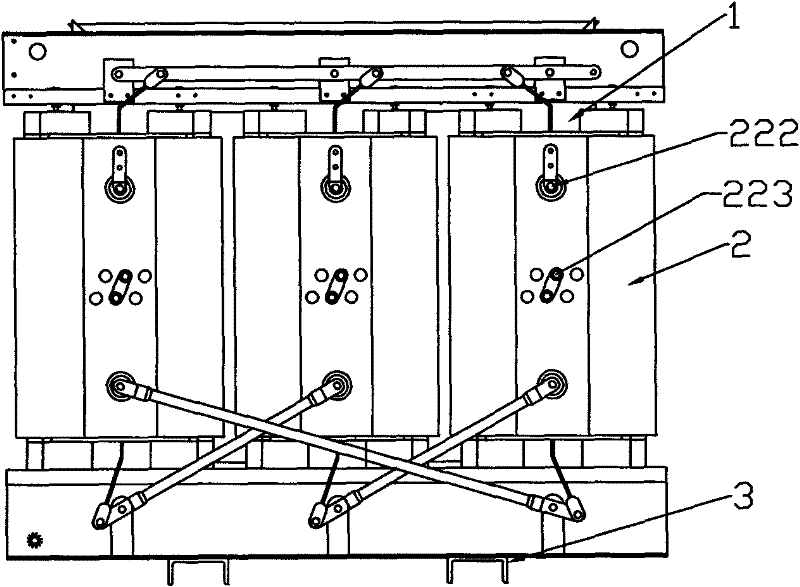

[0009] Such as figure 1 As shown, this kind of wire-foil mixed-wound coil grounding transformer includes an iron core 1 , a high-voltage coil 2 and a support frame 3 .

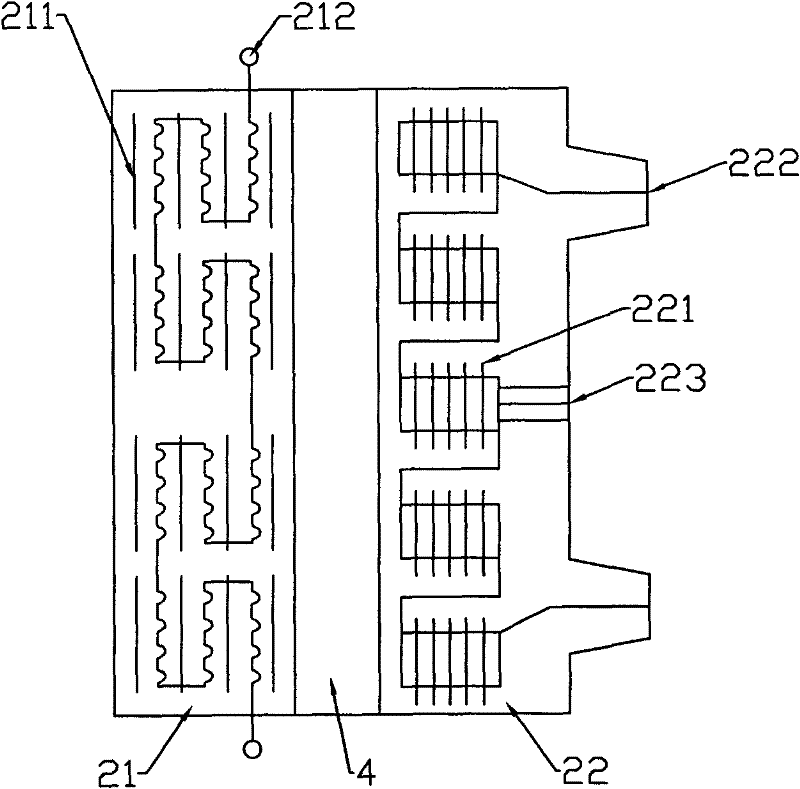

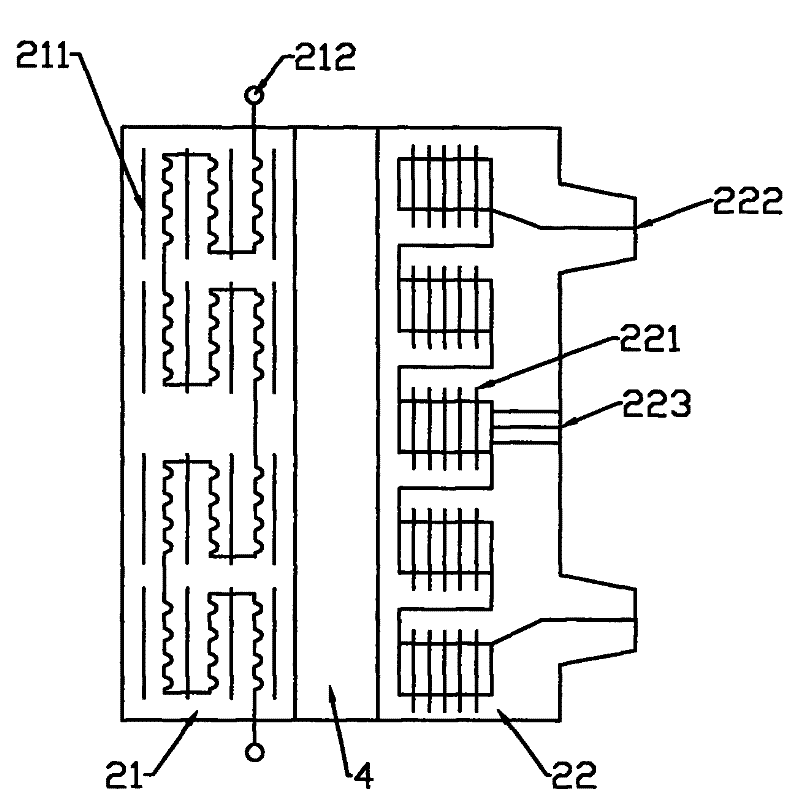

[0010] Such as figure 2 As shown, the high-voltage coil 2 includes an inner coil 21 and an outer coil 22, and an air channel 4 is provided between the inner coil 21 and the outer coil 22, and the air channel 4 axially penetrates the coil, thereby improving the Heat dissipation and overload capacity. The inner layer coil 21 is wound in layers using enamelled flat copper wire as the conductor, and a vacuum-impregnated glass grid plate 211 is arranged between each layer, and a high-pressure heat shrinkable plate is provided at both ends of the inner layer coil 21 respectively. The inner layer connection terminal 212 of the tube; the outer layer coil 22 is wound in sections using copper foil as a conductor, an electrical insulating base film 221 is provided between each turn, and outer layer connection terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com