Plastic bracket structure of motor with replaceable carbon brush

A technology of bracket structure and carbon brush, which is applied in the direction of casing/housing/support, electrical components, electromechanical devices, etc., can solve problems such as unreliable contact, reduced motor performance, and increased axial length, so as to ensure uniform effective force performance, improve overload capacity, and increase motor life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

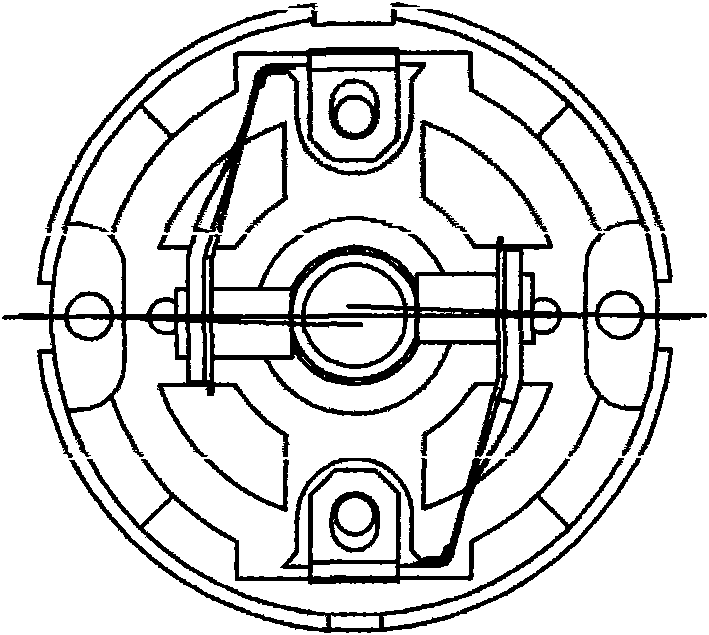

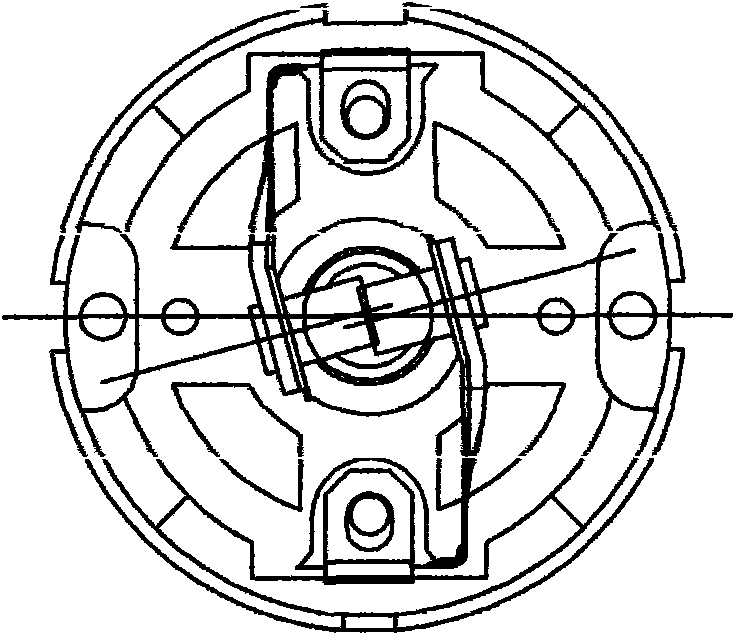

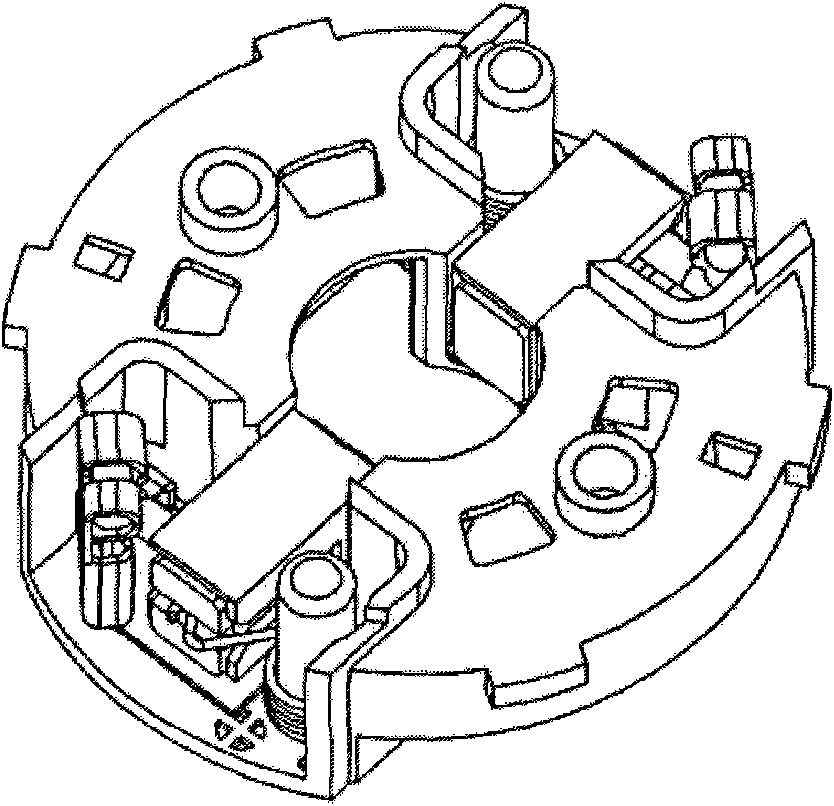

[0032] like figure 2 , 3 And shown in accompanying drawing 4 (A), (B), a kind of motor plastic support structure of replaceable carbon brush, comprises plastic support 1, brush box 2, plastic cylinder 3, carbon brush spring 4, carbon brush assembly 5 and terminal Component 6, on both sides of the plastic bracket 1, two completely symmetrical external small cavities are designed. The brush box 2, plastic cylinder 3, carbon brush spring 4, carbon brush component 5 and terminal component 6 are arranged in the small cavity, and the plastic cylinder 3 is arranged vertically upward on one side of the small cavity, and 4 sets of carbon brush springs are placed on the plastic cylinder 3 for positioning; the edge of the plastic bracket 1 close to the plastic cylinder 3 is in the shape of an arc.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com