Conveyor

A technology for conveying devices and control devices, which is applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., and can solve problems such as damage to substrate straightness, vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

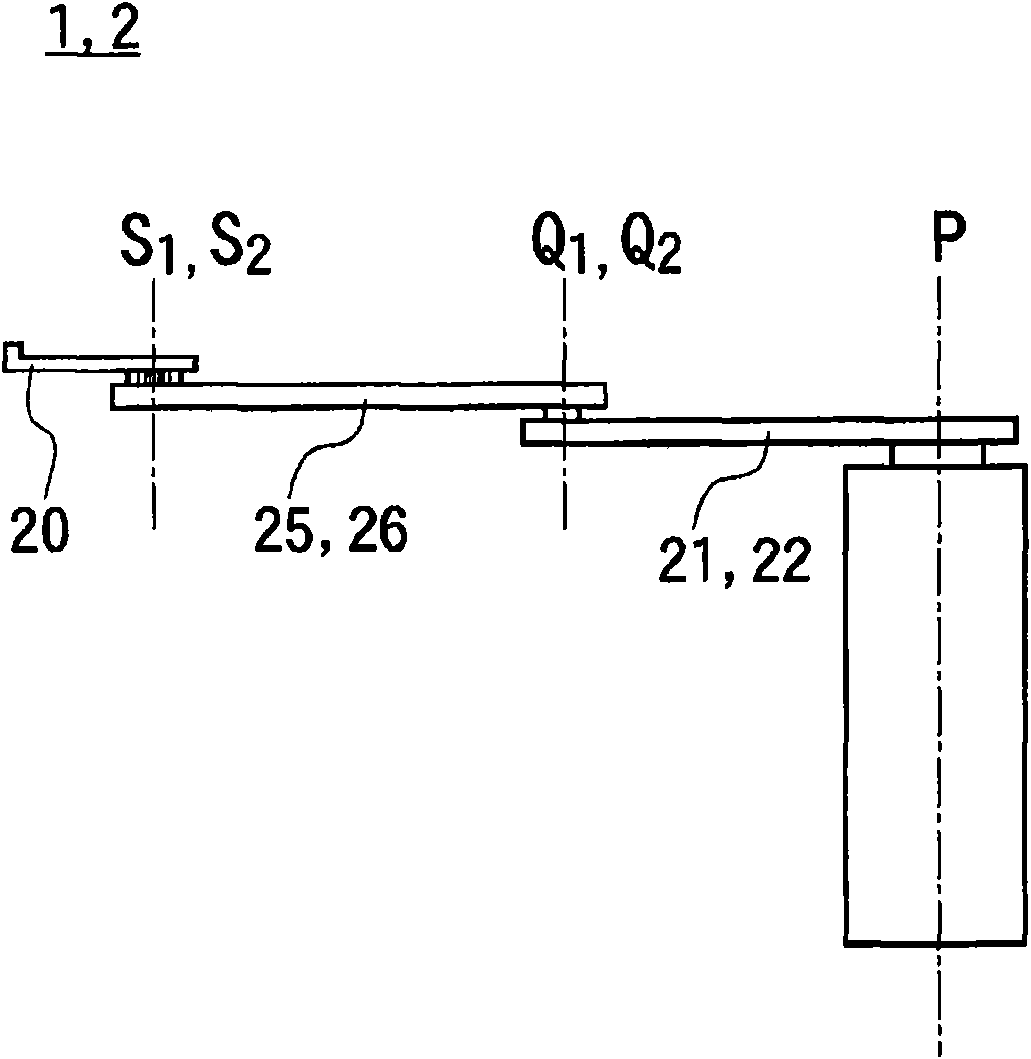

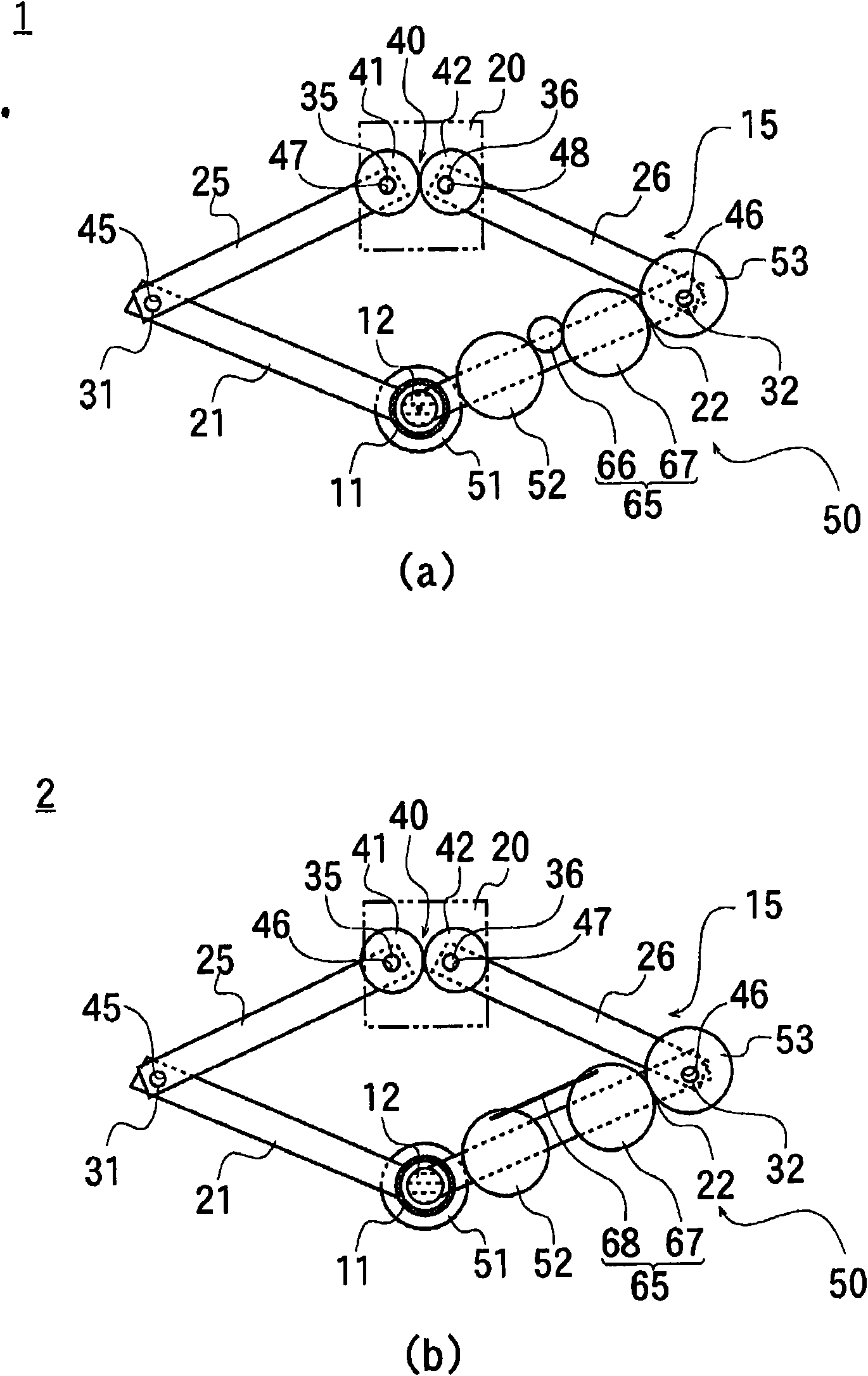

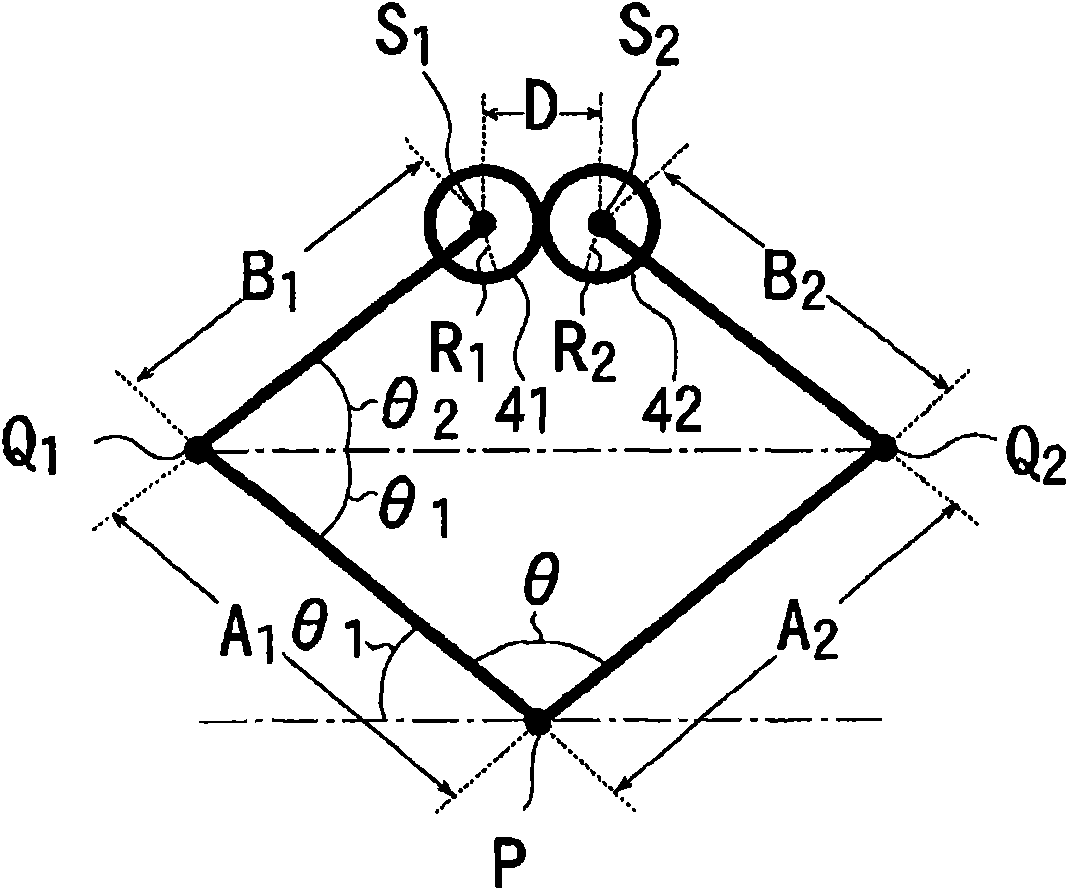

[0174] Figure 9 The structure of the conveyance apparatus 110 which concerns on 1st Embodiment of this invention of a 2nd category is shown.

[0175] The transport device 110 of this embodiment includes: a base 103 having a pair of rotating shafts 101, 102 rotating in different directions; a pair of first arms 111, 112 connected to one end of the rotating shafts 101, 102; a pair of second arms 121 , 122 , one end of which is rotatably coupled to the respective other ends of these first arms 111 , 112 via arm coupling shafts 113 , 114 ; The substrate supports 104 to which the other ends are bonded.

[0176] The first arms 111 , 112 and the second arms 121 , 122 have the same arm length, thereby forming a parallel link mechanism. Therefore, the angle ω formed by the first arms 111, 112 and the second arms 121, 122 is changed by rotating the rotation shafts 101, 102 in opposite directions, and the substrate support 104 moves vertically in the figure. Thereby, the substrate w ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com