Method for producing an acoustically resistive structure, resulting acoustically resistive structure and skin using one such structure

A manufacturing method and damping technology, which is applied to the manufacture of damping and sound-absorbing structures, can solve problems such as difficulty in positioning reinforced structures, reducing the effect of sound-absorbing treatment, and blocking fabric meshes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The invention now described applies to the air intake of an aircraft propulsion plant. However, the invention can be applied to various parts of the aircraft that have been treated for sound dampening, such as the leading edge of a wing or any part that must withstand high temperatures, such as near the engine or near the blades of the engine

[0043] In the following description, whether it is frost or ice, it refers to ice and frost of various properties, various structures and thicknesses.

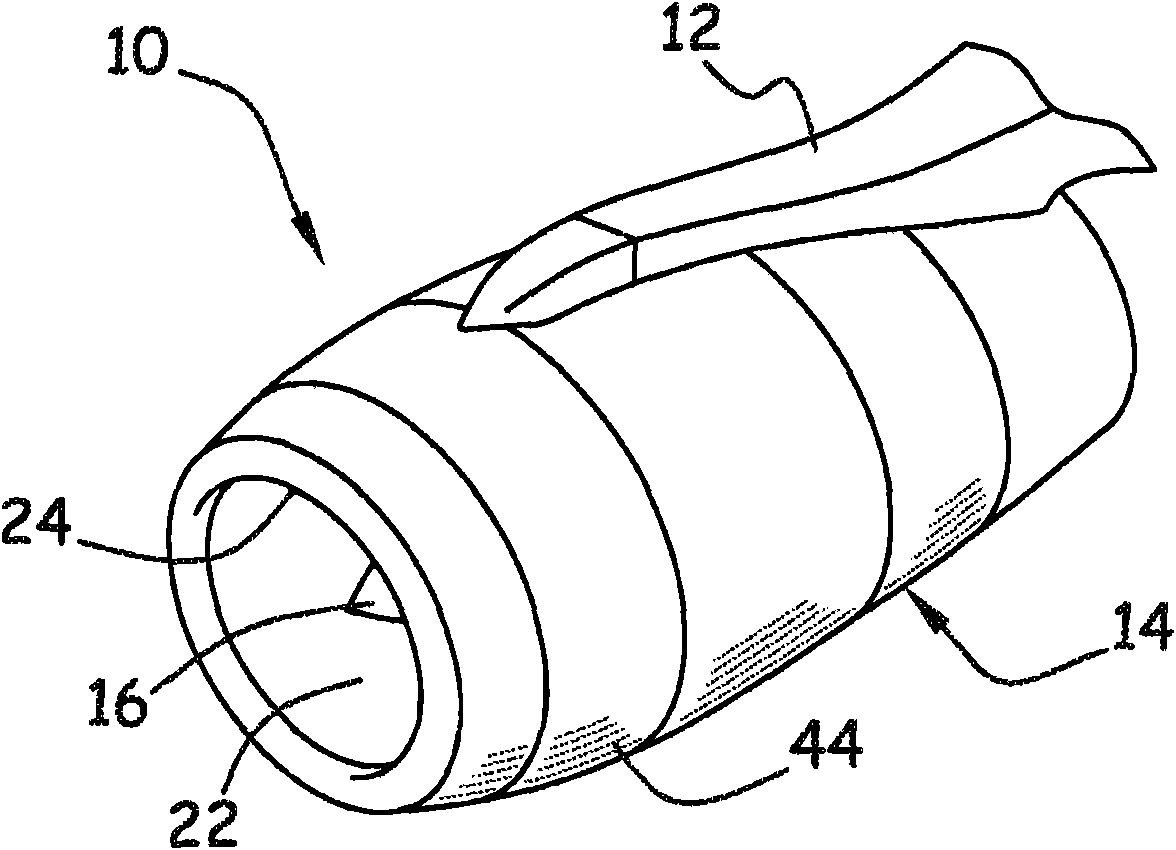

[0044] figure 1 A propulsion device 10 of an aircraft is shown, which is connected under the wing by struts 12 . However, this propulsion unit can also be connected to other areas of the aircraft.

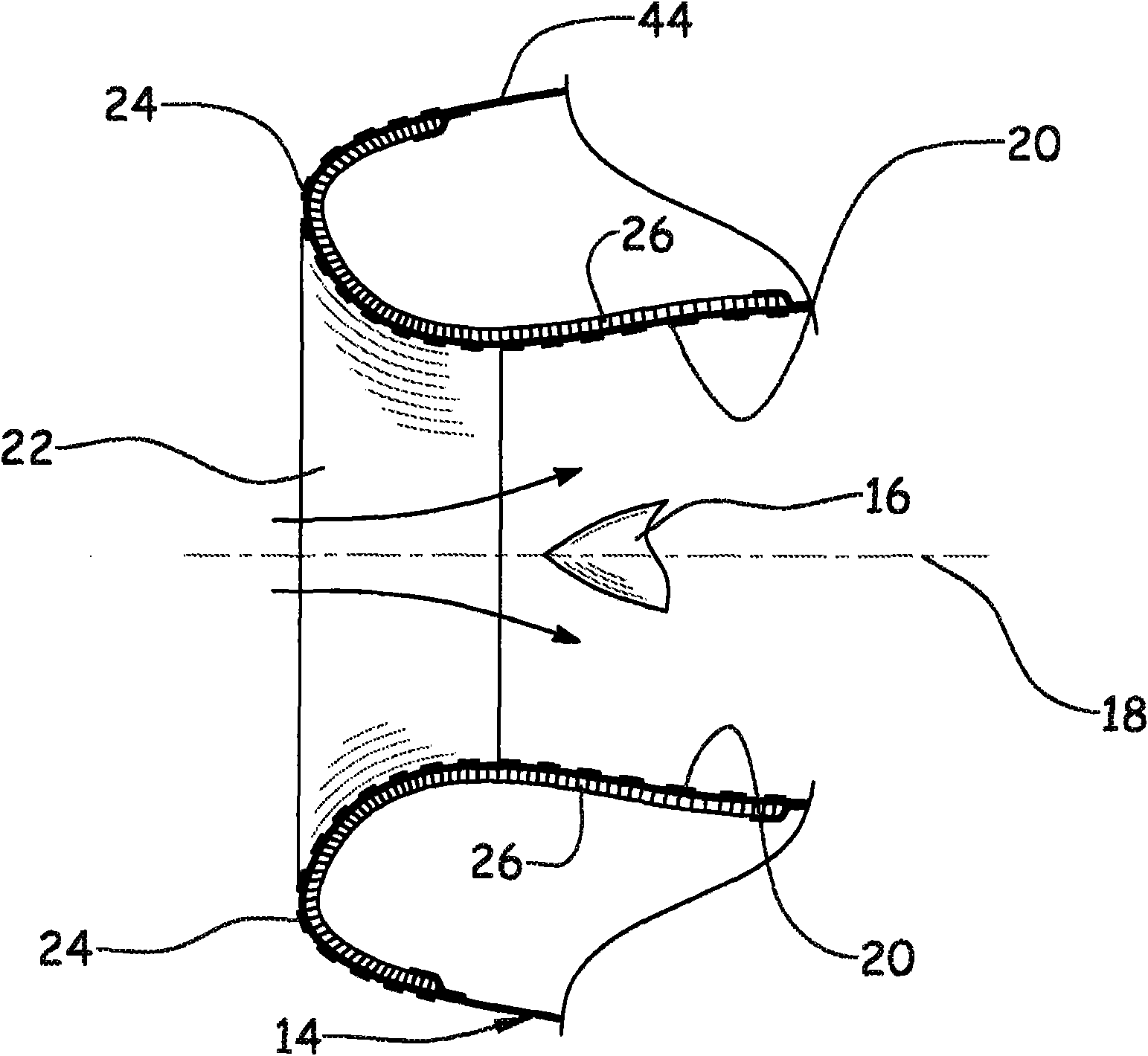

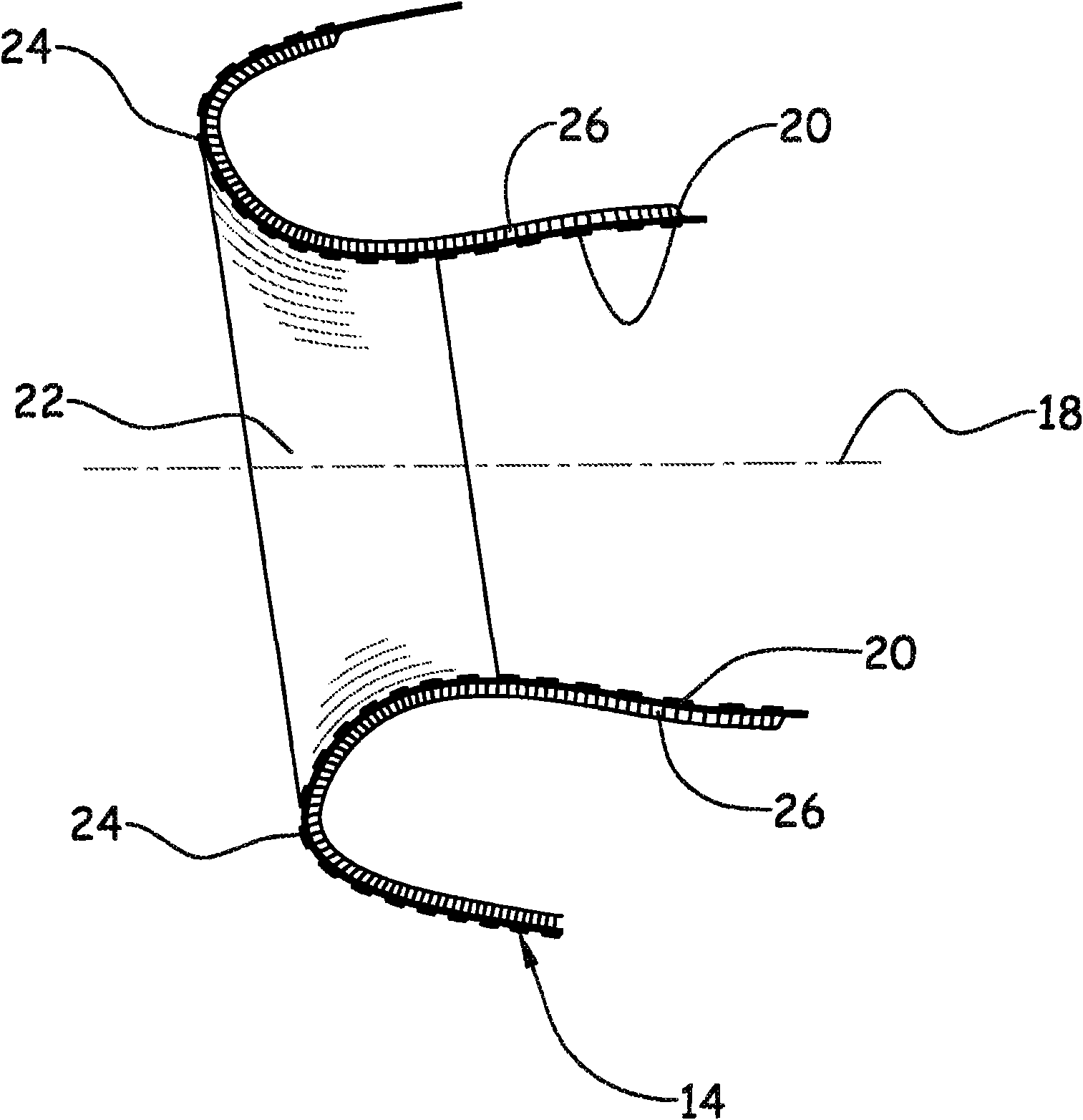

[0045] The propulsion means comprise an engine nacelle 14 in which are mounted power units in a generally concentric manner to drive an air intake mounted on a main shaft 16 . The longitudinal axis of the nacelle is identified by reference numeral 18 .

[0046] The nacelle 14 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com