Method of machining for producing a bearing surface on a cylinder wall of a cylinder liner of an internal combustion engine

A technology for internal combustion engines and working surfaces, which is applied in the direction of manufacturing tools, metal processing equipment, cylinders, etc., can solve problems such as unbalanced, unfavorable presets, and obstacles, and achieve combination optimization, sufficient oil retention volume, and effective and full exchange Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

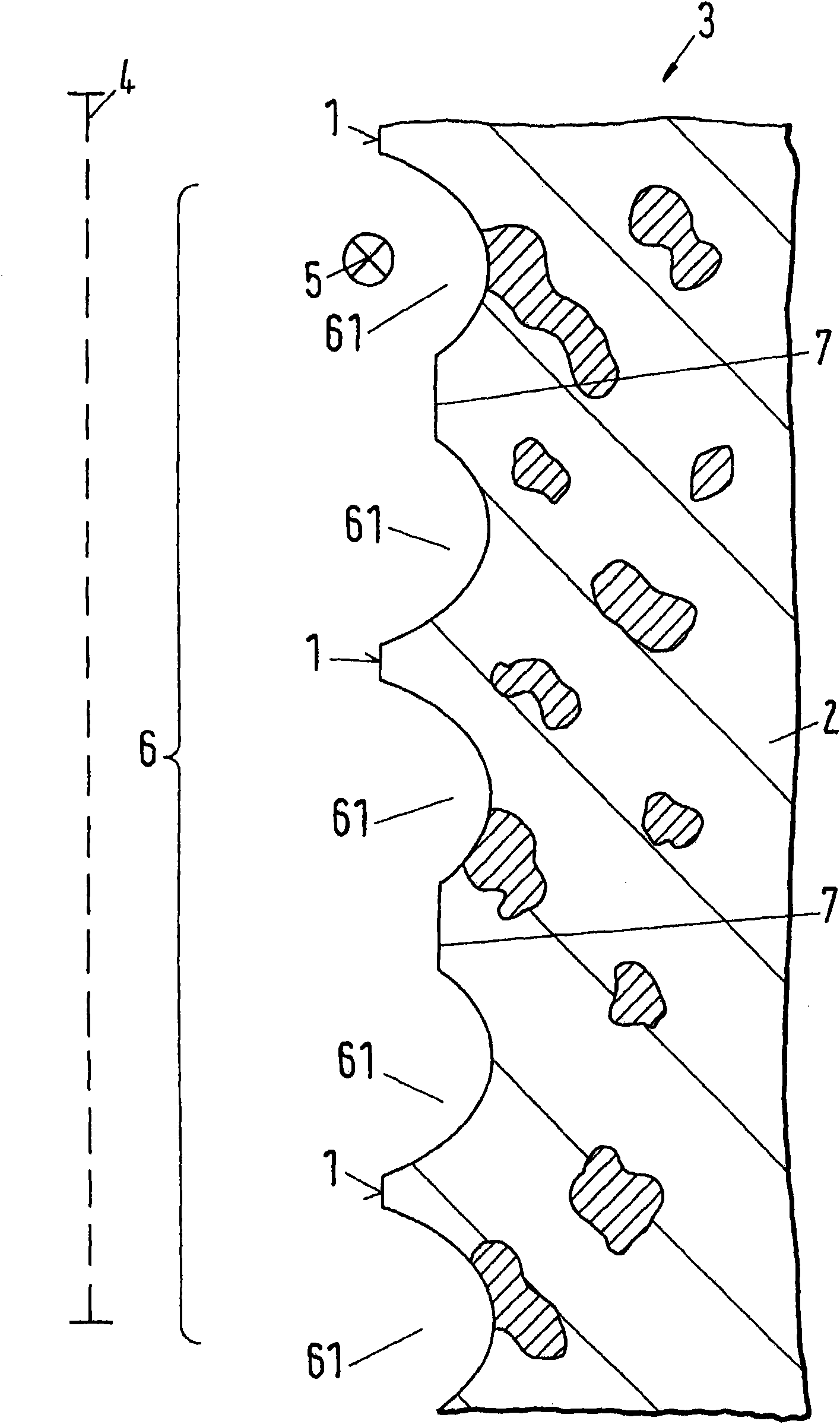

[0051] exist figure 1 , schematically shows a detail according to the invention of a longitudinal section through a running face 1 of a cylinder liner 3 produced according to a particularly preferred embodiment of the method according to the invention.

[0052] A running surface 1 can be clearly seen which is arranged on the cylinder wall 2 of a cylinder liner 3 of a large two-stroke diesel engine operating at low speed. not in figure 1 The piston shown in is arranged in a known manner in a mounted state in a cylinder liner 3 and reciprocates along the running surface 1 in the direction of the cylinder axis 4 in the operating state of the large diesel engine.

[0053] In this respect, the running surface is produced from the cylinder liner blank 31 by machining, such as turning, of the cylinder wall 2 , that is, in three steps, channel-shaped roughnesses are firstly machined, such as turned, on the cylindrical inner surface of the cylinder liner blank 31 . Structure 8. A di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com