Heat exchange compressor

A technology of heat compression and heat exchange tubes, which is applied in the field of heat exchange compressors and heating devices in the coating industry, which can solve the problems of exhaust emissions polluting the environment and dust blockage, and achieve the effect of long heat exchange distance and lower fuel cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

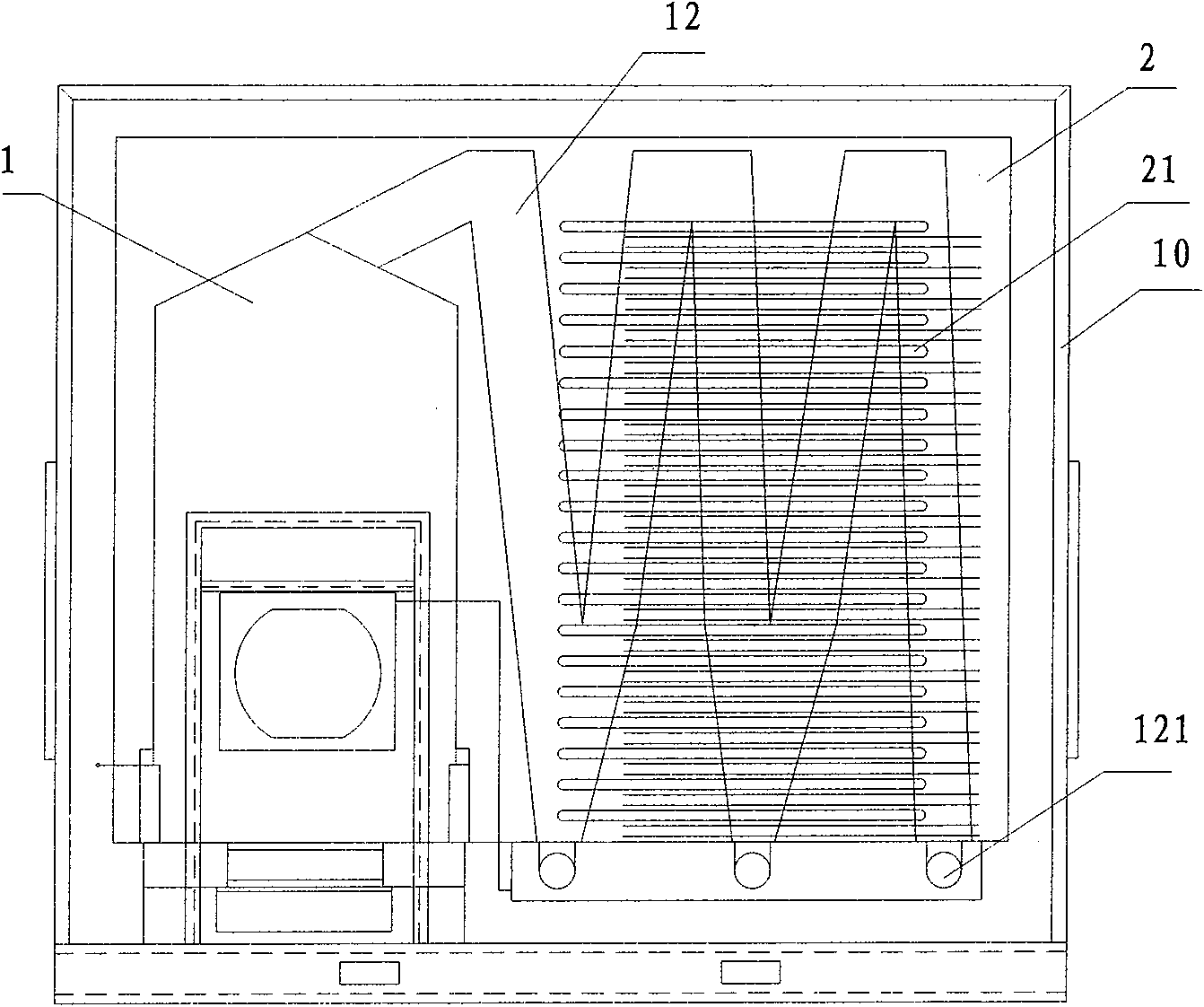

[0024] For the present invention, a preferred embodiment is now described in detail in conjunction with the drawings, as figure 1 As shown, the heat exchange compressor is mainly composed of a heating furnace 1, a heat exchange compression box 2, an air intake pipe 12, an exhaust pipe 5, an S-shaped heat exchange pipe 21 and an exhaust gas purification device. Its specific structure is as follows:

[0025] The heating furnace 1 is located on one side of the heat exchange compression box 2. The heating furnace 1 can realize automatic filling of fuel, and two intake pipes 12 are connected to the top of the heating furnace 1; the heating furnace 1 and the heat exchange compression box 2 are located in a closed shell 10 , between the heating furnace 1 and the heat exchange compression box 2 in the closed shell 10 are separated by a screen; the closed shell 10 is provided with several closed openings that can be opened and closed according to requirements;

[0026] Located on one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com