Method and device for preventing ice coating in electric transmission line

A transmission line, anti-icing technology, applied in the installation of cables, overhead lines/cable equipment, overhead installation, etc., can solve the problems of large investment, aging coating, no anti-icing coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

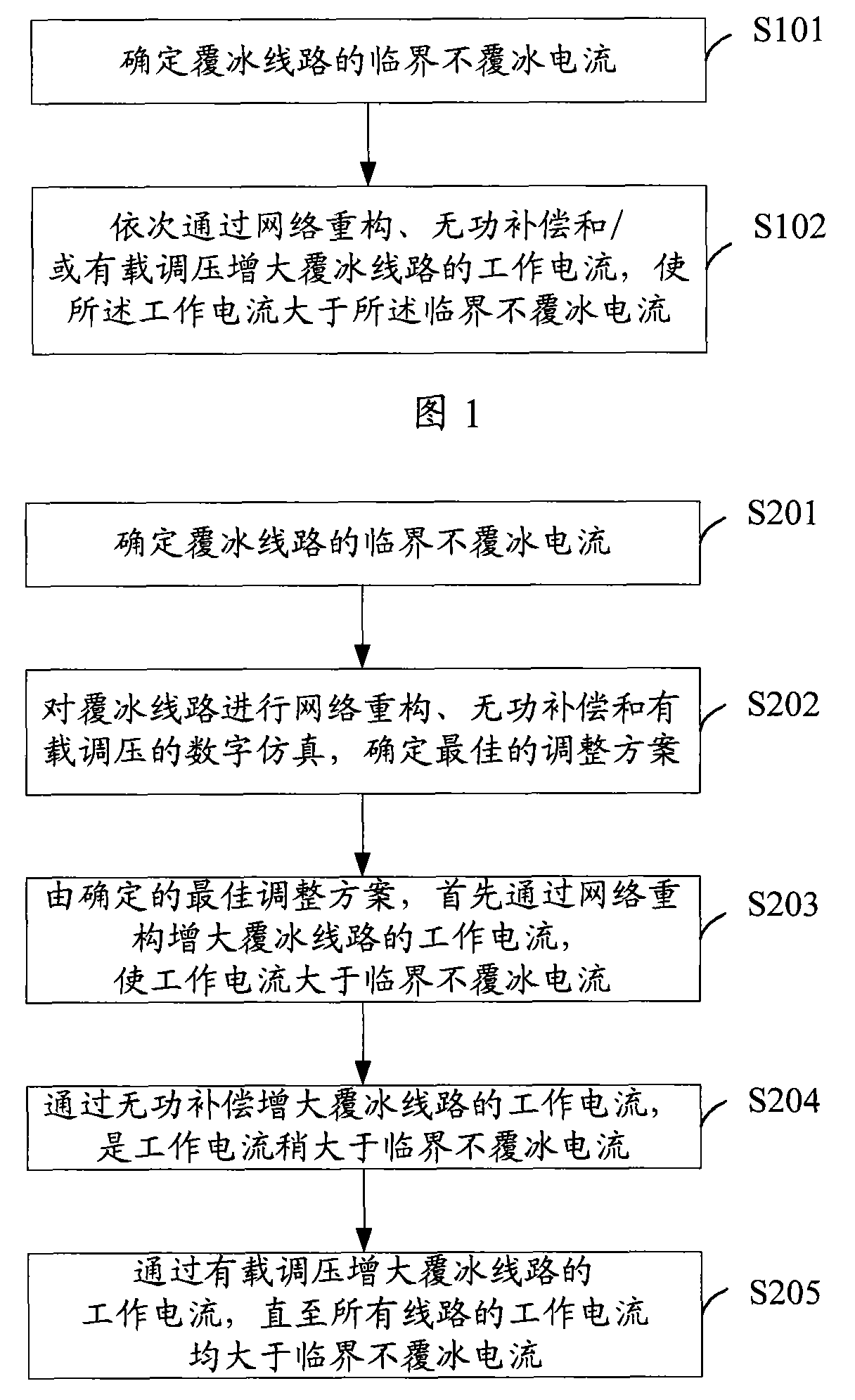

[0060] Refer to Fig. 1, which is a flowchart of a first embodiment of a method for preventing ice coating on a transmission line according to the present invention.

[0061] S101: Determine the critical non-icing current of the icing circuit.

[0062] Select the possible ice-coated lines through the ice-coated area from the power grid, and calculate the critical non-icing current of the possible ice-coated lines according to the selected line model, the number of splits and the meteorological conditions of the area where the line passes.

[0063] The line type, number of splits, and weather conditions in the passing area are different, the icing current of the line is different.

[0064] S102: Increase the working current of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com