Double-rope drawing endless rope continuous traction system

A traction system and rope traction technology, which is applied in the direction of movable tracks, railway car body parts, roads, etc., can solve the problem of increasing the area, volume, and weight of the endless rope winch, which is inconvenient for the endless rope winch to carry and transport large-tonnage coal mines Auxiliary equipment is difficult and other problems to achieve the effect of preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

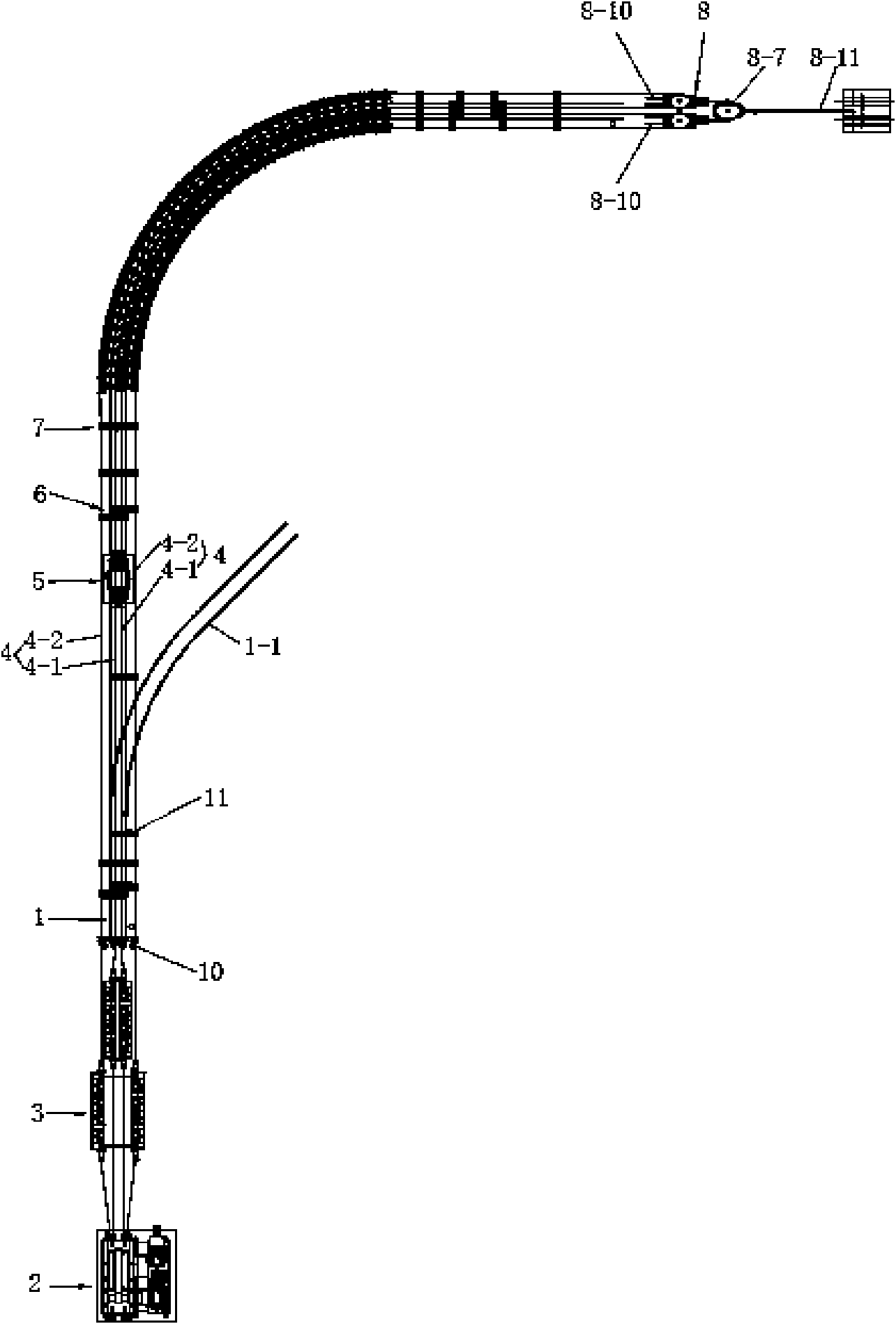

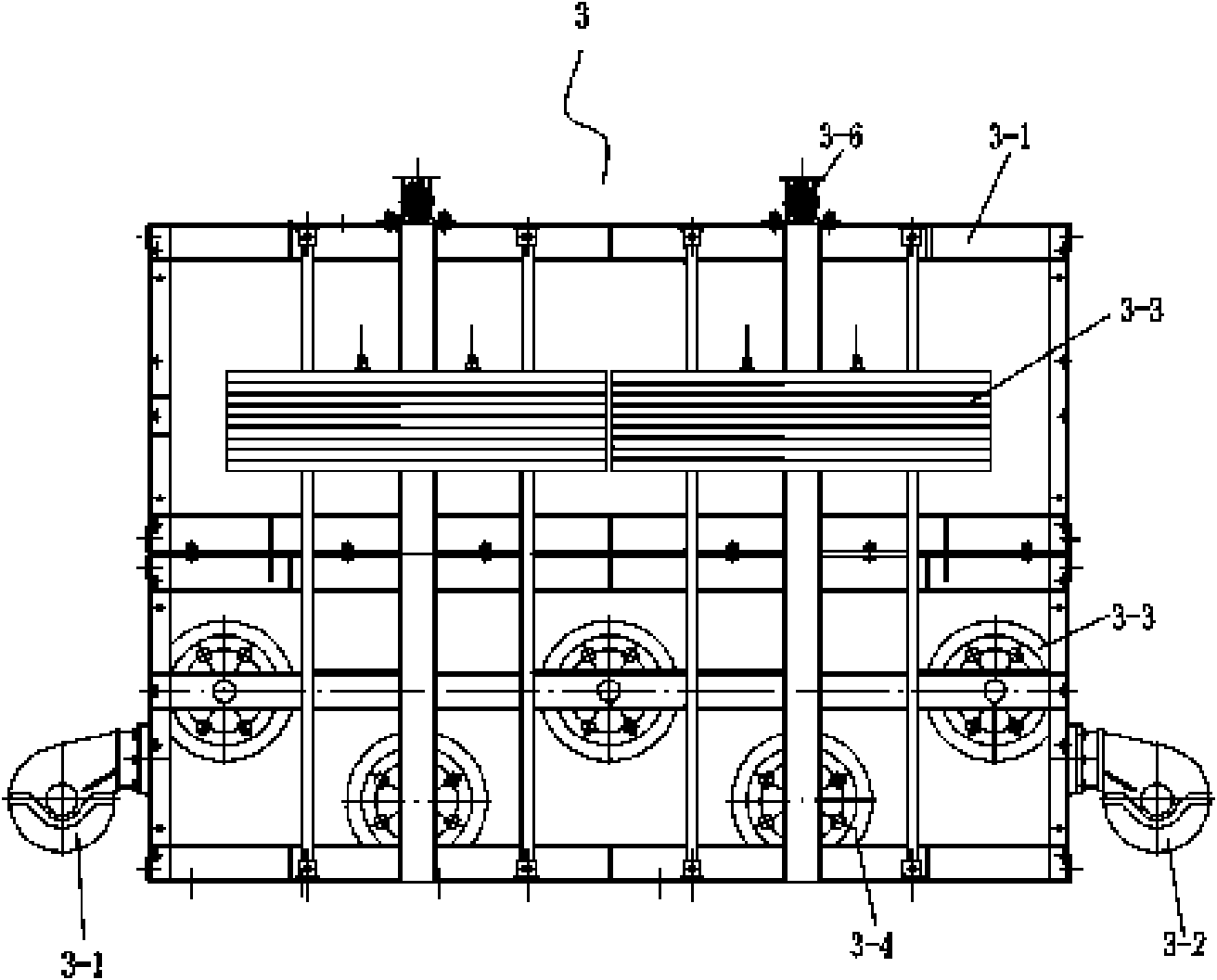

[0035] See figure 1 , the system includes a main track 1, an endless rope winch 2, a traction wire rope 4, a wire rope tensioning device, a shuttle car 5 and a tail wheel 8-7 at the system tail.

[0036] The traction wire rope 4 is two closed traction wire ropes arranged side by side. Two ropes in the middle of the four ropes of the two closed traction wire ropes are main ropes 4-1, and the ropes on both sides are auxiliary ropes 4-2.

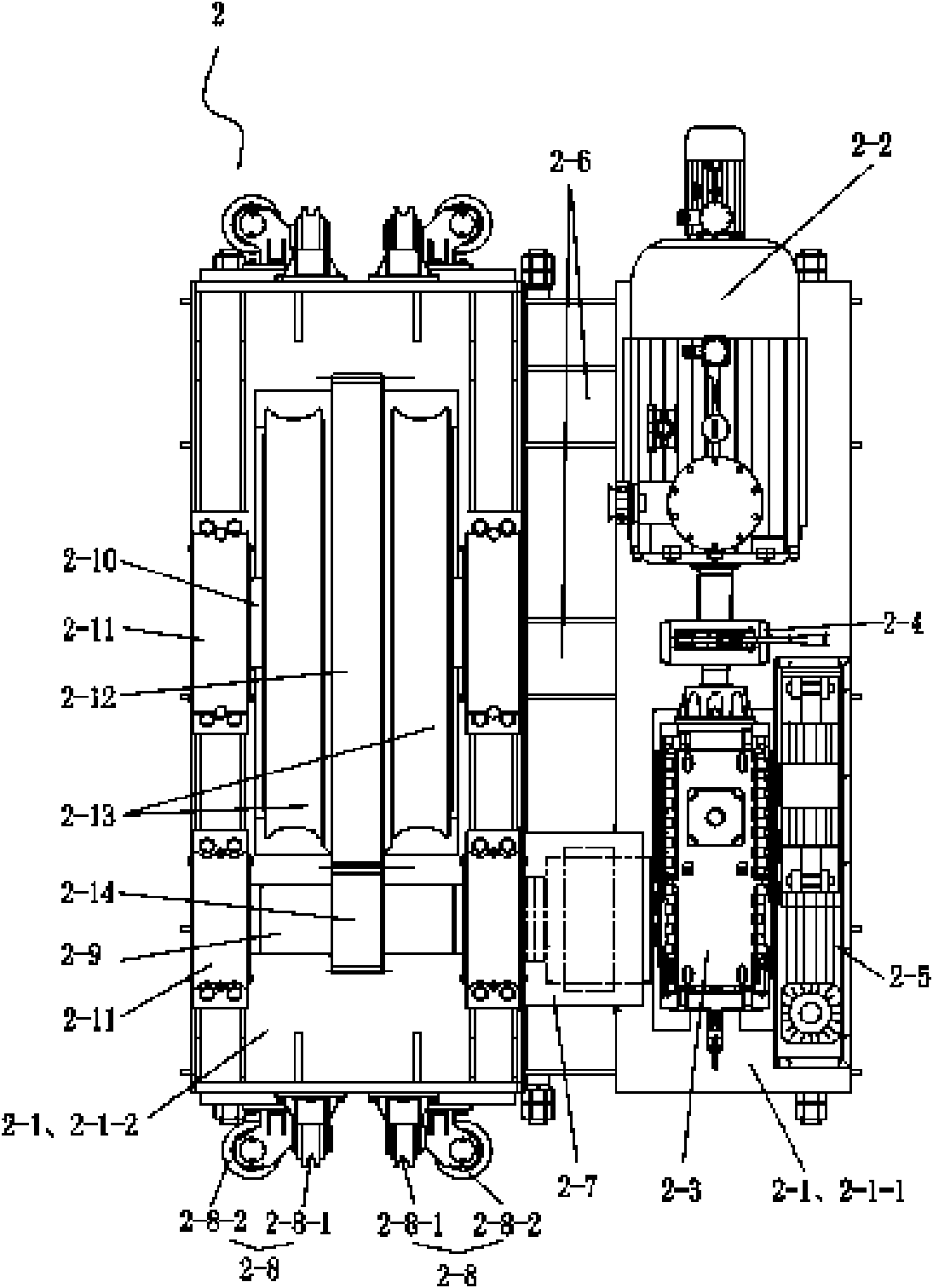

[0037] See figure 1 and figure 2 , the endless rope winch 2 has a base 2-1, a flameproof motor 2-2, a reducer 2-3, a brake 2-5 connected to the reducer 2-3, and two pairs of bearing housings 2-11, two pairs of bearings The seat 2-11 supports the driving shaft 2-9 and the driven shaft 2-10 respectively, and the driving shaft 2-9 and the driven shaft 2-10 are respectively provided with a pinion 2-14 and a bull gear 2-12. The two pairs of bearing housings 2-11 adopt Haval bearing housings with upper and lower shell structures, which facilitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com