Method for preparing lead-based ferroelectric thin film with controllable texture at low crystallization temperature

A ferroelectric thin film, low crystallization technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of unfavorable large-area Si integrated circuit applications, difficult texture control, high crystallization temperature, etc., to achieve low cost, The effect of smooth surface and low crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

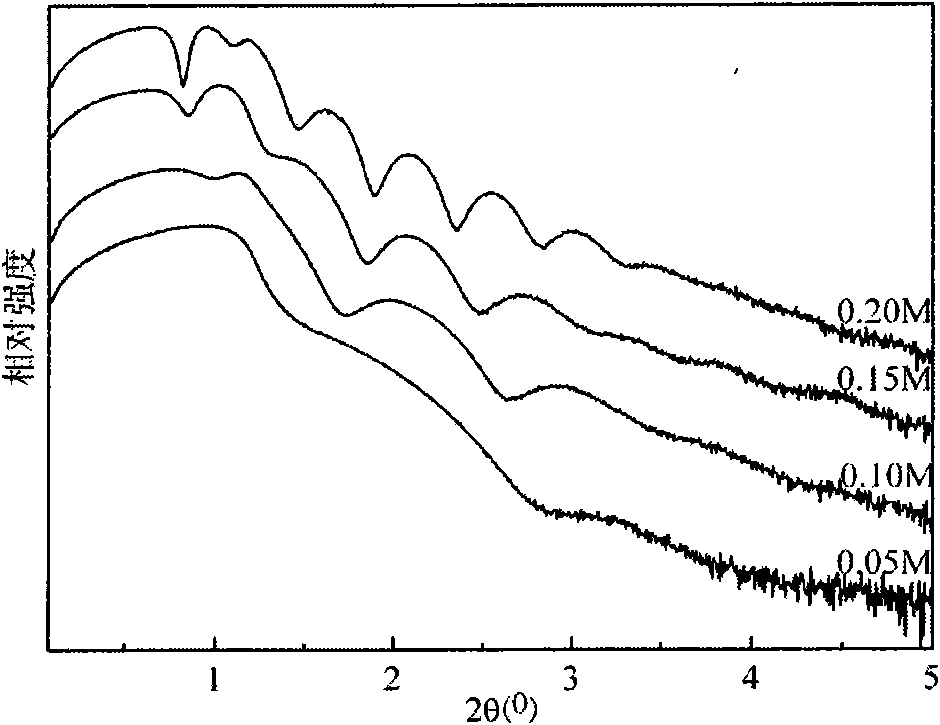

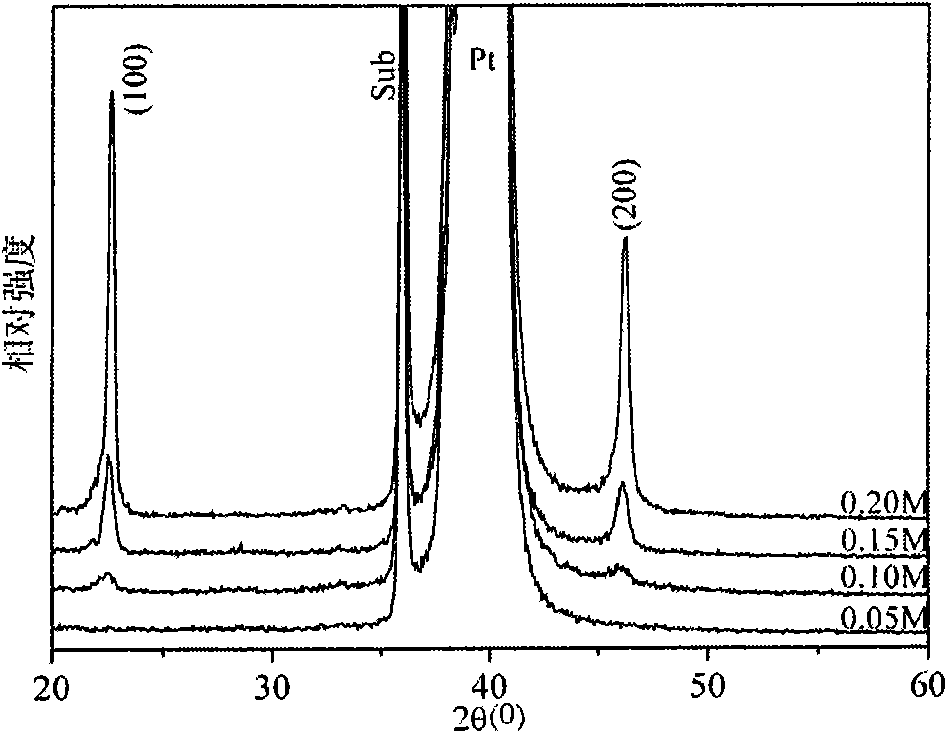

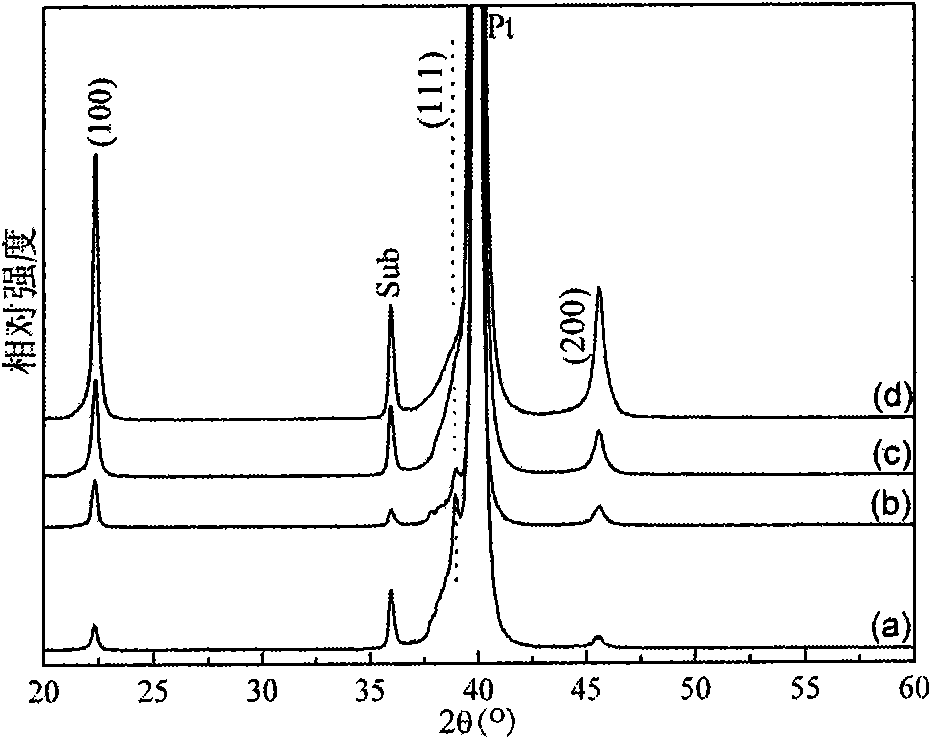

[0010] Specific implementation mode 1: The preparation of a texture-controllable lead-based ferroelectric thin film at a low crystallization temperature in this implementation method is realized by the following steps: 1. Deposit a layer of lanthanum titanate-calcium-lead-based iron with a thickness of 5-20 nm on the substrate The electric thin film is then annealed and crystallized at a temperature of 400-450°C to obtain a seed layer film A; 2. On the seed layer film A, continue to deposit a lead titanate-based ferroelectric film with a thickness of 200-300nm, Then annealing and crystallization treatment is carried out at a temperature of 450-700° C. to obtain a lead-based ferroelectric film with a controllable texture; wherein the molecular formula of the lanthanum titanate-calcium-lead-based ferroelectric film in step 1 is (Pb 1-x-y La x Ca y ) Ti 1-x / 4 O 3 , wherein 0≤X≤0.24, 0≤Y≤0.24; in the second step, the lead titanate ferroelectric film is a lead titanate ferroelec...

specific Embodiment approach 2

[0013] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the substrate in step 1 is Pt / Ti / SiO 2 / Si substrate. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the thickness of the lanthanum calcium lead-based ferroelectric thin film in step 1 is 10 nm. Other steps and process parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com