Production method for industrial naphthalene

A production method and technology of industrial naphthalene, which is applied in the field of industrial naphthalene production, can solve the problems of low industrial naphthalene output, high naphthalene content in raw materials, and low separation efficiency, and achieve high product yield, low operating costs, and good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

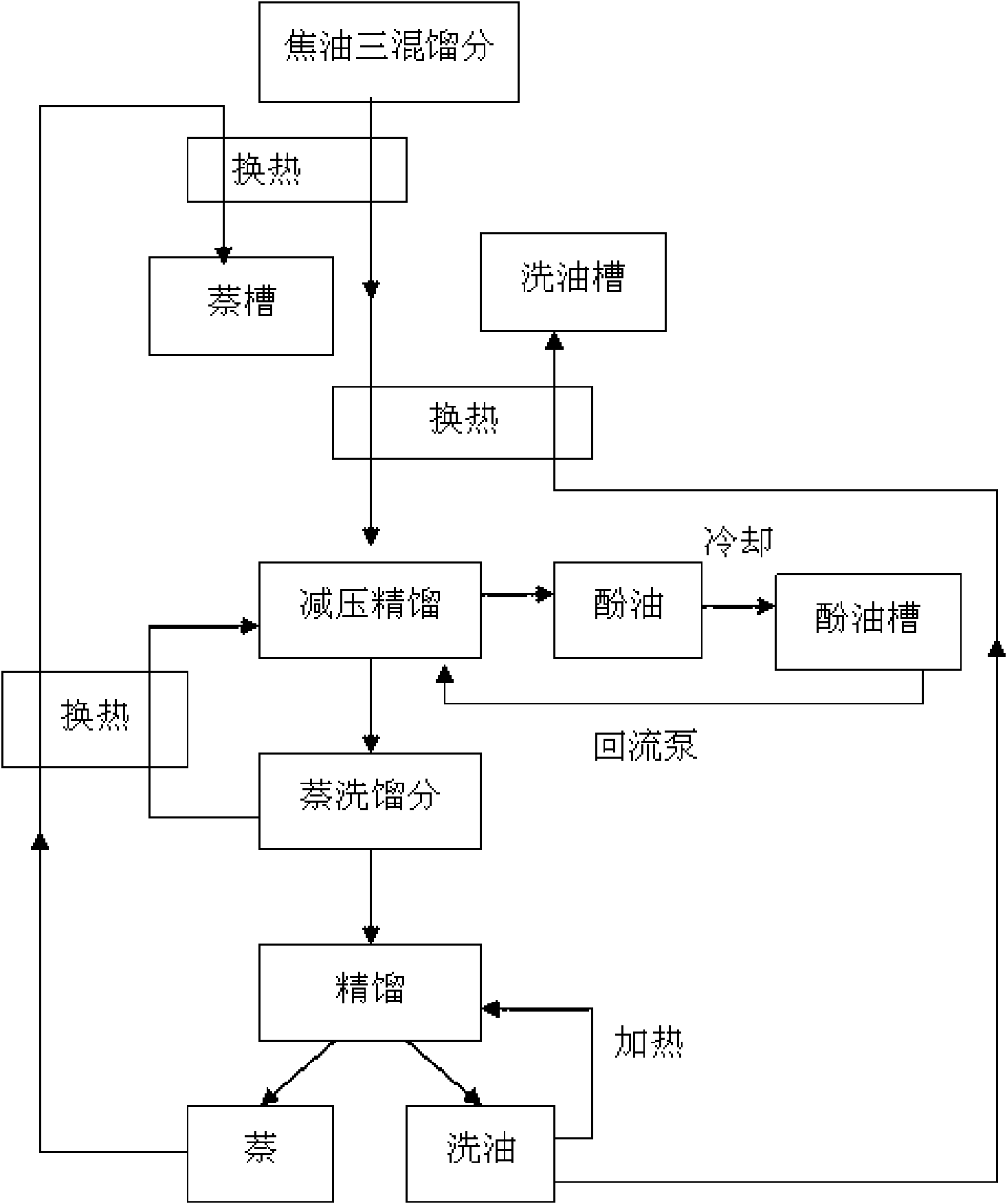

[0023] The tar tri-mixed fraction containing 40-70% naphthalene is first passed into the tar tri-mixed fraction tank, and then sent into the tar tri-mixed fraction / industrial naphthalene heat exchanger, tar tri-mixed fraction / washing oil heat exchanger to 150 ~ 170 ° C into the initial distillation column. The initial distillation tower adopts vacuum distillation, the temperature at the top of the tower is 150-155°C, and the pressure is 15-35kPa. The phenol oil extracted from the top of the initial distillation tower is condensed and cooled, and after the oil and water are separated, part of it is used as reflux, and the rest is extracted as a product; The naphthalene-washed fraction is extracted from the bottom, part of the naphthalene-washed fraction is sent to the reboiler of the primary distillation tower to exchange heat with the naphthalene vapor from the top of the rectification tower to 190-195°C, and then returned to the primary distillation tower as a heat source, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com