Low-noise micro-arc oxidation device

A micro-arc oxidation and low-noise technology, applied in anodizing and other directions, can solve problems such as high noise, and achieve the effects of safety reduction, transmission intensity reduction, and easy observation and detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

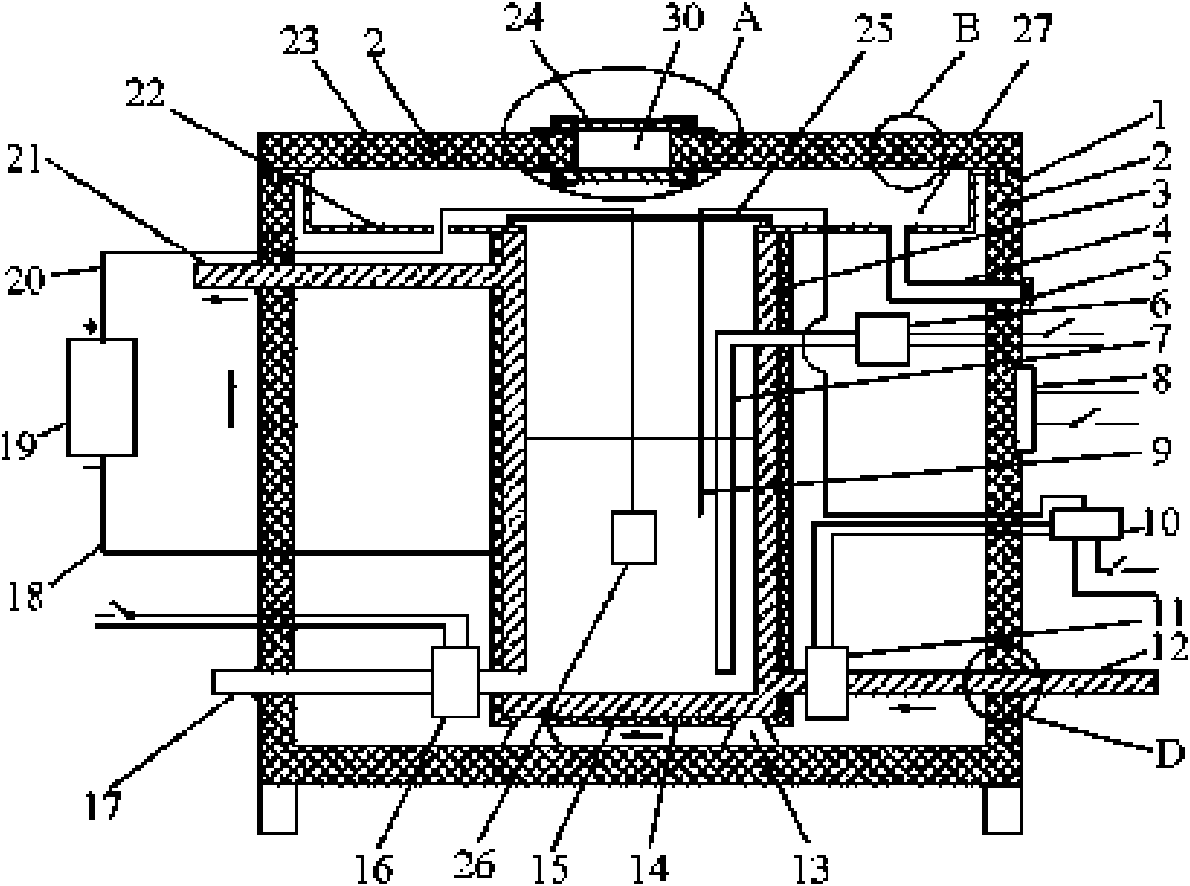

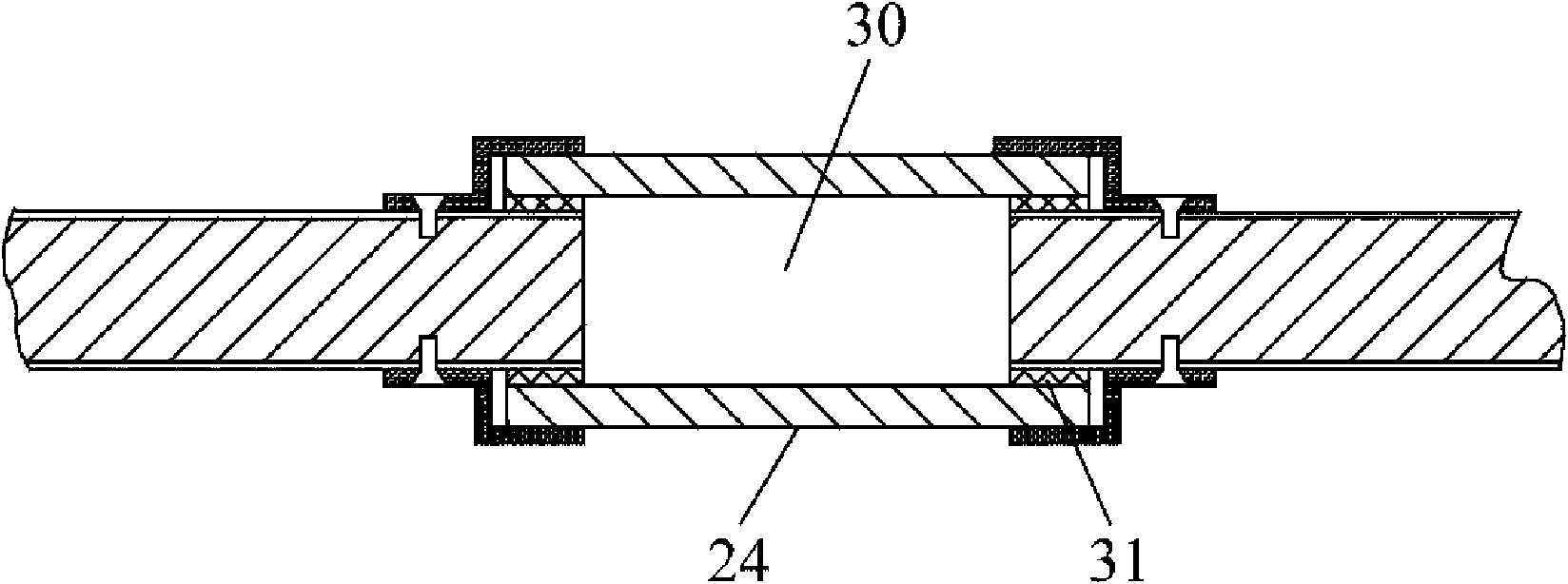

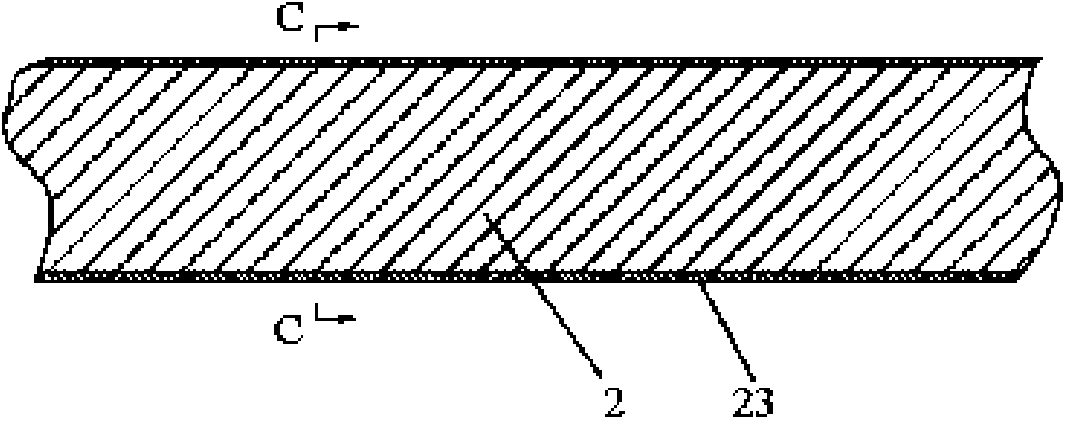

[0008] Specific implementation mode 1: Combination Figure 1-Figure 6 To explain this embodiment, the micro-arc oxidation device of this embodiment includes a box body 1, a gas discharge pipe 4, an exhaust fan 5, an air pump 6, an air pipe 7, a cooling water pump 11, a cooling water inlet pipe 12, and a barrel with a cooling water jacket. Stainless steel electrolyzer 14, solution discharge pipe 17, micro-arc oxidation cathode 18, micro-arc oxidation power supply 19, micro-arc oxidation anode 20, cooling water outlet pipe 21, tank cover 23 and micro-arc oxidation insulating anode support 25; The oxidation device also includes a soundproof material 2, a flexible sound-absorbing material 3, and a stainless steel shutter 22; the tank 1 is equipped with a barrel-shaped stainless steel electrolytic tank 14 with a cooling water jacket, and the stainless steel shutter 22 is arranged on the tank 1 On the end surface and the upper end surface of the barrel-shaped stainless steel electrol...

specific Embodiment approach 2

[0009] Specific implementation manner two: combination figure 1 To illustrate this embodiment, the box 1 of this embodiment is made of a metal material, a wood board or an organic material board, which can be selected as required. Others are the same as the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 with Figure 4 To illustrate this embodiment, the box cover 23 of this embodiment is composed of a tank body 28 and a cover plate 29; the lower end of the tank body 28 is connected to the cover plate 29, which is made of stainless steel or organic material, and water vapor is not easy to Corrosion, the tank body 28 is made of metal material, wood board or organic material board. Others are the same as the first or second embodiment.

[0011] Specific implementation manner 4: Combination figure 1 To illustrate this embodiment, the flexible sound-absorbing material 3 of this embodiment is a fiber yarn with a sound-absorbing function, a flexible benzene board or a sound-absorbing sponge. Others are the same as the first embodiment.

[0012] Specific implementation manner five: combination figure 1 To describe this embodiment, the sound insulation material 2 of this embodiment is a fiber yarn with a sound absorption funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com