Reinforced cement mixing pile composite foundation treatment and construction method

A technology of cement mixing piles and composite foundations, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of low strength and long age of cement mixing piles, achieve shortened construction period, fast construction period, and improve foundation bearing capacity force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

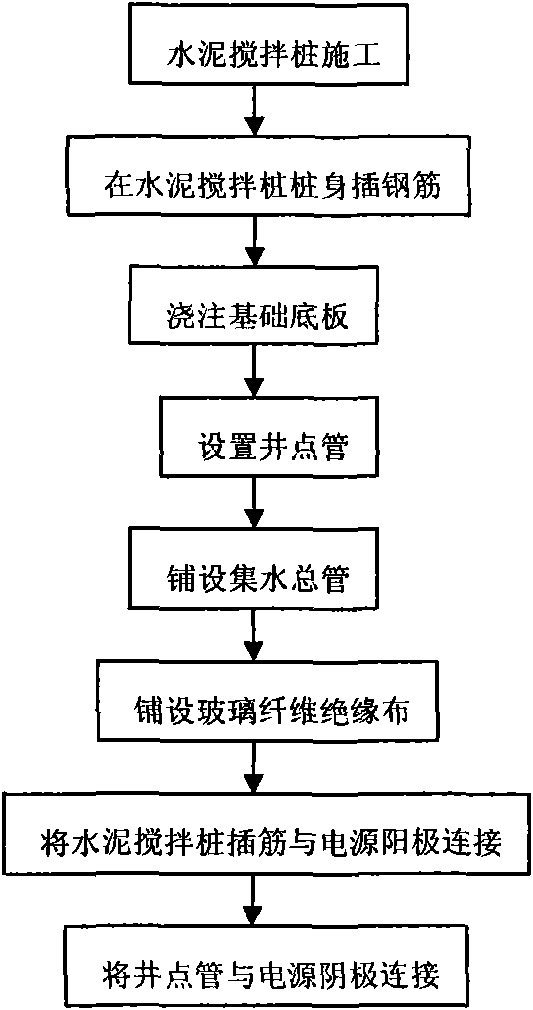

Image

Examples

Embodiment Construction

[0025] An office building is a 6-story frame structure with a building area of 5600m 2 , the thickness of highly compressible silt is 11m, and the water content is as high as 90%. The foundation uses reinforced cement mixing pile composite foundation for foundation treatment. The length of the cement mixing pile is 14m. After the construction of the foundation floor is completed, well point pipes are set on the periphery of the foundation floor for electroosmotic dewatering while the upper structure is being constructed. The cement mixing pile is used as the anode, and the well point tube is used as the cathode. Under the action of the electric field, the positively charged pore water flows to the cathode, and the cathode uses the well point tube, so the water in the muddy soil is forced to flow into the well point tube, and then pumped from the well point tube, causing the groundwater table to gradually drop. The negatively charged soil particles move towards the anode, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com