Telescopic brush type gland ring

A brush-type steam seal, telescopic technology, applied in the direction of preventing leakage, engine components, machines/engines, etc., to achieve the effect of reducing leakage, simple and reasonable structure, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The accompanying drawings disclose several specific embodiments of the present invention without limitation, which are further described as follows in conjunction with the accompanying drawings.

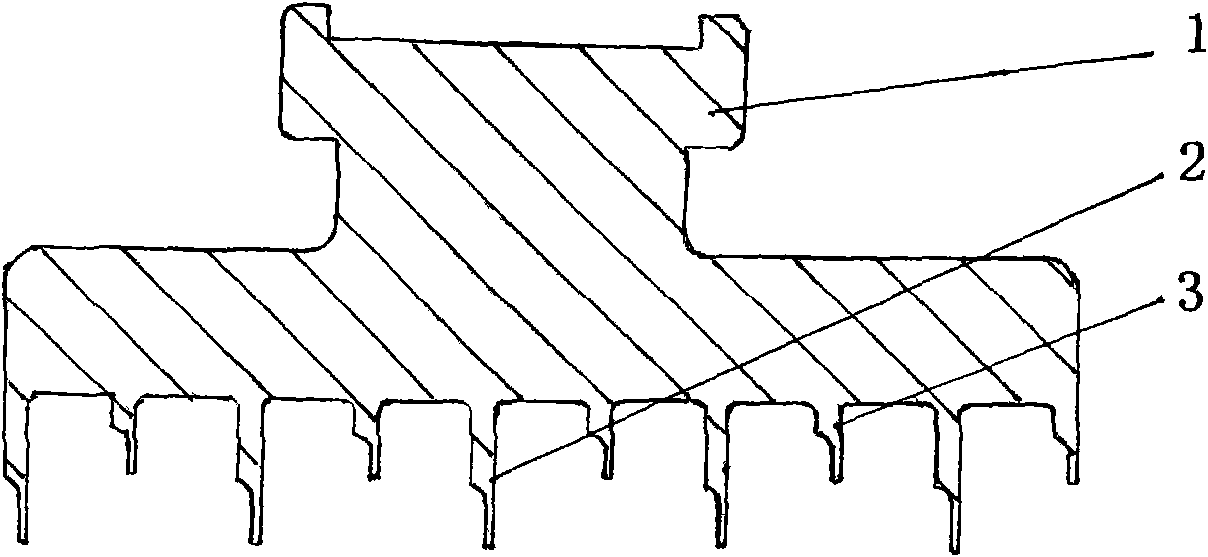

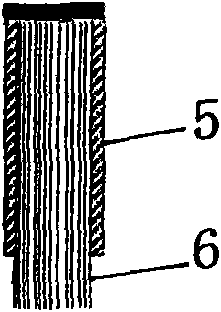

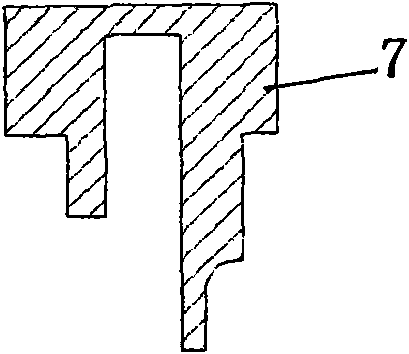

[0016] Referring to accompanying drawing, 1 among the figure is ring body, and 2 is high-tooth sealing strip, and 3 is low-tooth sealing strip, and 4 is sheet spring, and 5 is splint, and 6 is wire layer, and 7 is brush body.

[0017] The telescopic brush-type steam seal ring of the present invention is formed by connecting several sections of steam seal rings end to end, and each section of steam seal ring includes a ring body 1, a high-tooth seal strip 2, a low-tooth seal strip 3 and a telescopic seal brush, and A T-shaped groove is arranged on the ring body corresponding to the sealing brush, and the sealing brush includes a brush head (such as figure 2 shown) and T-shaped brush body 7 (as image 3 shown), the brush head is composed of closely arranged metal wire layers 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com