Process for manufacturing monocrystalline silicon solar cell texture with low surface reflectivity

A solar cell and manufacturing process technology, applied in the field of solar energy applications, can solve the problems of restricting solar cell efficiency, large light reflection loss, weakened long-wave absorption, etc., and achieves the effects of simple manufacturing process, low surface reflectivity, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1) Put a silicon wafer with a thickness of 180±5μm and a size of 20mm×20mm into a 20mt% KOH solution, and react at 80°C for 2min to remove the surface damage of the silicon wafer;

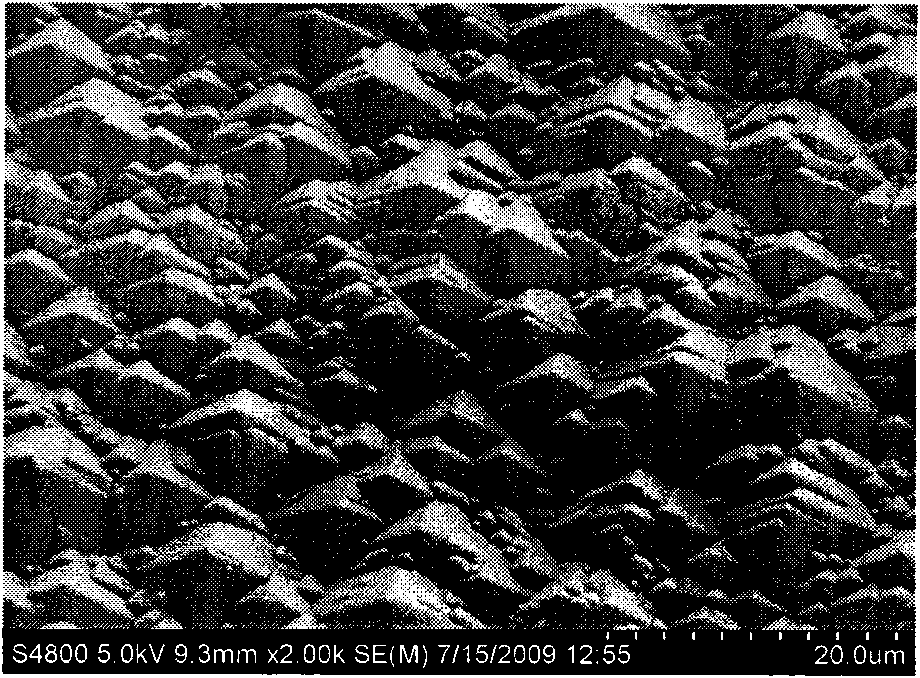

[0014] 2) Put the cleaned silicon chip into a mixed solution of KOH and isopropanol, wherein the concentration of KOH is 3mt%, and the concentration of isopropanol is 8vol%, react at 80°C for 60min, and form on the surface of the silicon chip Pyramid structures of uniform size (see figure 1 );

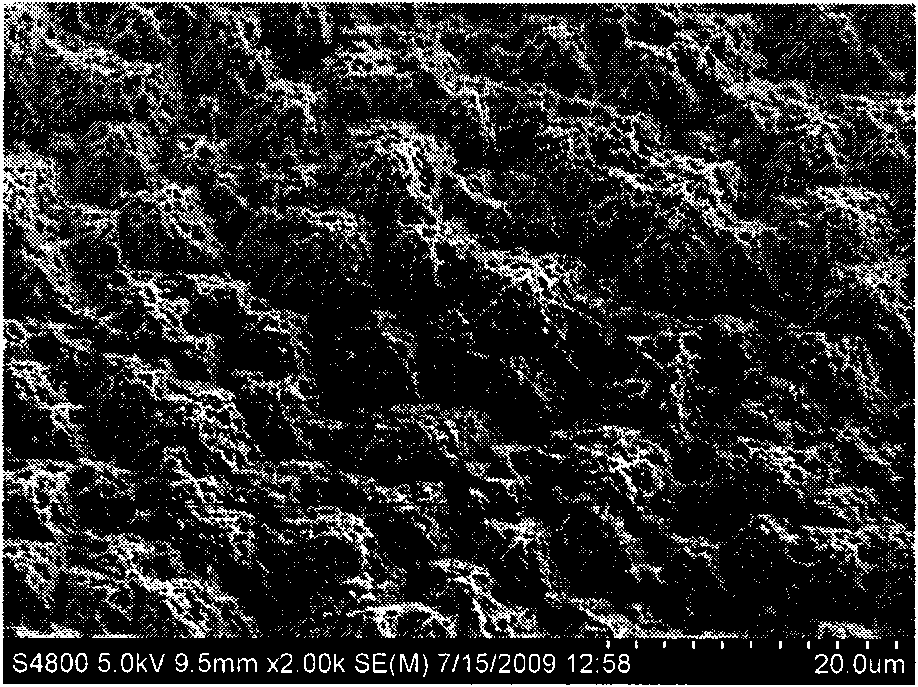

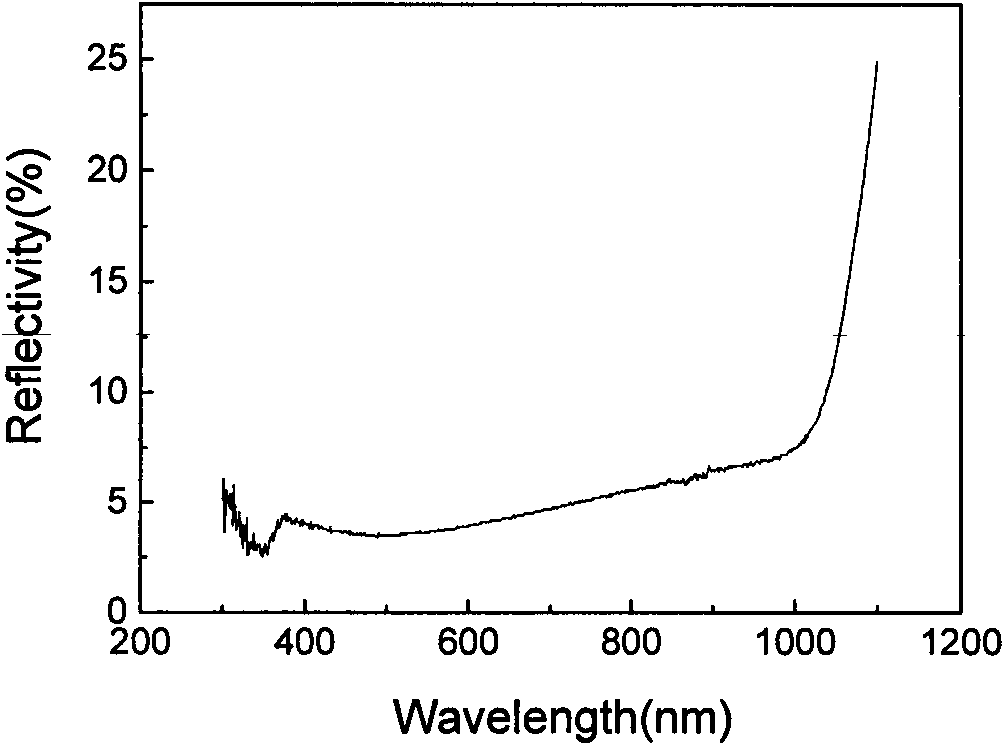

[0015] 3) Put the silicon chip with a pyramid structure in step 2) into a polytetrafluoroethylene kettle filled with corrosive liquid, seal it, and react at 50°C for 30 minutes, the corrosive liquid is 10mol / L HF+0.2mol / L Fe (NO 3 ) 3 The mixed solution forms porous silicon on the surface of the pyramid, see figure 2 , the porous structure on the surface of the pyramid structure is conducive to the further absorption of incident light. The low surface reflectance of the monocrystalline silicon s...

Embodiment 2

[0017] 1) Put a silicon wafer with a thickness of 180±5μm and a size of 20mm×20mm into a 20mt% KOH solution, and react at 80°C for 2min to remove the surface damage of the silicon wafer;

[0018] 2) Put the cleaned silicon chip into a mixed solution of KOH and isopropanol, wherein the concentration of KOH is 3mt%, and the concentration of isopropanol is 8vol%, react at 80°C for 60min, and form on the surface of the silicon chip Pyramid structure of uniform size;

[0019] 3) Put the silicon chip with a pyramid structure in step 2) into a polytetrafluoroethylene kettle filled with corrosive liquid, seal it, and react at 10°C for 60 minutes, the corrosive liquid is 5mol / L HF+0.4mol / L Fe (NO 3 ) 3 The mixed solution forms porous silicon on the surface of the pyramid to obtain the textured surface of the monocrystalline silicon solar cell with low surface reflectance, and the average reflectance is 8.2% in the visible light range of 400nm to 800nm.

Embodiment 3

[0021] The size of the original silicon wafer (180±5μm) used is 20mm×20mm. First, use 20mt% KOH solution to remove the surface damage of the silicon wafer, and react at 80°C for 2min; ℃ for 60min, then in 15mol / L HF+0.1mol / L Fe(NO 3 ) 3 When the reaction time in the solution is 10 minutes, the average reflectance obtained in the range of visible light (400nm-800nm) is 6.9%.

[0022] 1) Put a silicon wafer with a thickness of 180±5μm and a size of 20mm×20mm into a 20mt% KOH solution, and react at 80°C for 2min to remove the surface damage of the silicon wafer;

[0023] 2) Put the cleaned silicon chip into a mixed solution of KOH and isopropanol, wherein the concentration of KOH is 3mt%, and the concentration of isopropanol is 8vol%, react at 80°C for 60min, and form on the surface of the silicon chip Pyramid structure of uniform size;

[0024] 3) Put the silicon chip with a pyramid structure in step 2) into a polytetrafluoroethylene kettle filled with corrosive liquid, seal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com