Semiconductor integrated circuit

A technology of integrated circuits and semiconductors, applied in the field of semiconductor integrated circuits, can solve problems such as inability to change comb teeth, difficult-to-comb capacitors, and ensure capacitor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

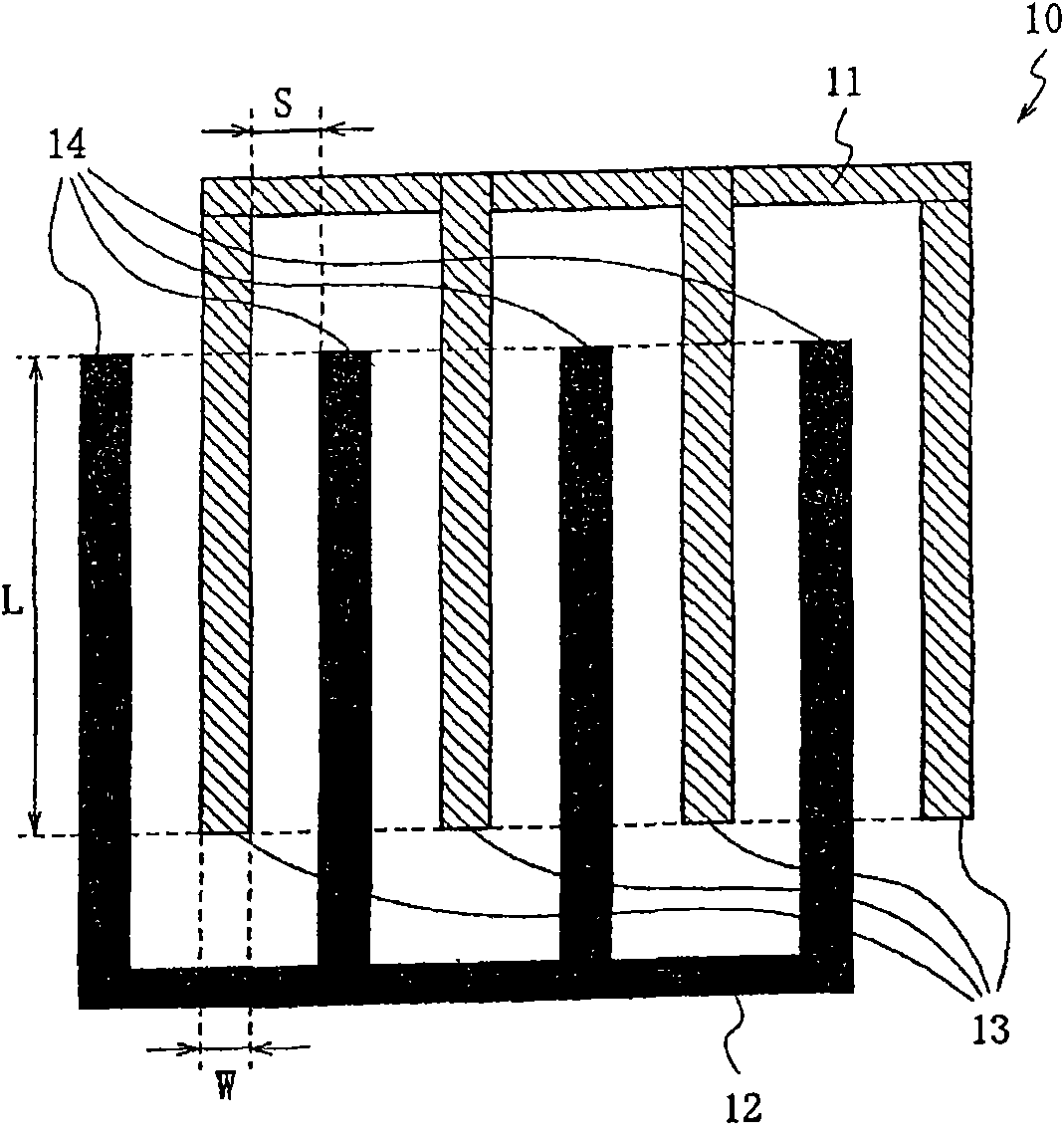

figure 1 The structure of the analog macro comb capacitor mounted on the semiconductor integrated circuit of the first embodiment is shown. Here, an analog macro refers to a circuit composed of a plurality of analog elements. figure 1 The comb-shaped capacitor 10 shown has a comb-shaped electrode 11 and an electrode 12, and the comb-tooth portion 13 of the electrode 11 and the comb-tooth portion 14 of the electrode 12 are engaged to form, so that the comb-tooth portion 13 of the electrode 11 and the comb of the electrode 12 The teeth 14 are alternately arranged in parallel. Here, the electrode 11 and the electrode 12 respectively have four comb-tooth portions, but the present invention is not limited thereto, and the number of comb-tooth portions of the electrode 11 and the electrode 12 of the comb capacitor can be arbitrary.

[0052]

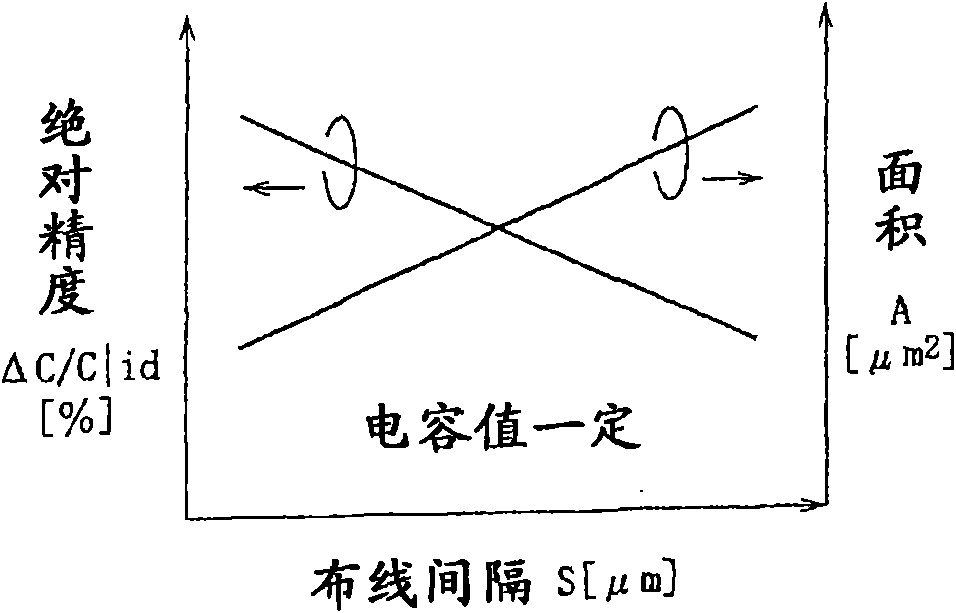

The first embodiment is characterized in that the comb-tooth interval S of the comb capacitor is set differently according to the absolute ...

Embodiment 2

The semiconductor integrated circuit of the second embodiment is characterized in that a plurality of analog macros having a plurality of comb capacitors are mounted, and the comb-tooth interval S of each comb capacitor of each analog macro is expressed as the distance between the adjacent comb capacitors. The relative accuracy of the difference between the capacitance values is set to be different.

[0118]

Such as figure 1 As shown, each comb-shaped capacitor has a comb-shaped electrode 11 and an electrode 12, and the comb-tooth portion 13 of the electrode 11 is formed by engaging with the comb-tooth portion 13 of the electrode 12. As a result, the comb-tooth portion 13 of the electrode 11 and the comb of the electrode 12 The teeth i4 are alternately arranged in parallel.

[0119]

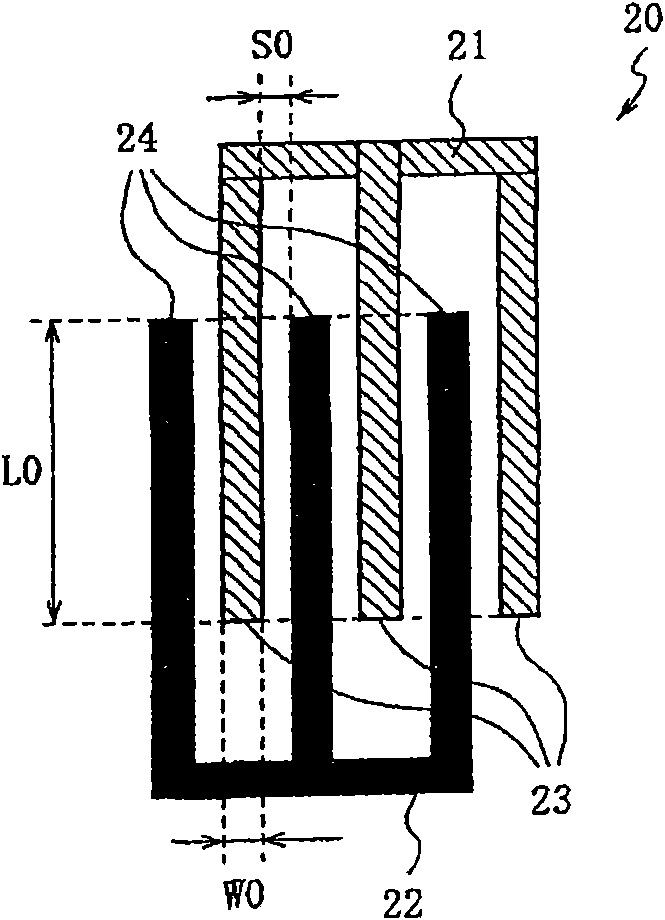

If the vacuum dielectric constant is ε0, the relative permittivity of the oxide film is εox, the ideal capacitance value is C, and the thickness of the comb tooth portion is h, the interlock...

Embodiment 3

The semiconductor integrated circuit of the third embodiment is characterized in that it is equipped with an analog macro having a plurality of analog circuit blocks including a plurality of comb-shaped capacitors, and the comb-tooth portion intervals of the comb-shaped capacitors are adjusted for each analog circuit block. vary.

[0151]

Figure 12 It is a block diagram showing a configuration example of an analog macro having a plurality of analog circuit blocks including comb capacitors. Figure 12 Among them, the analog macro 121 has five analog circuit blocks with different functions. Since the functions of the analog circuit blocks 1201, 1202, 1203, 1204, and 1205 are different, the required capacitance accuracy is also different. Therefore, each analog circuit block has a comb capacitance with a different comb-tooth interval S according to the required capacitance absolute accuracy or relative accuracy. Therefore, a high-density comb capacitor with a narrow comb-too...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com