Speed measurement system capable of improving speed control precision of incremental photoelectric encoder

A photoelectric encoder and speed control technology, which is applied in the field of speed measurement system, can solve the problems of speed measurement error and low speed control accuracy, and achieve the effects of reducing calculation error, improving absolute accuracy, improving machining accuracy and other control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

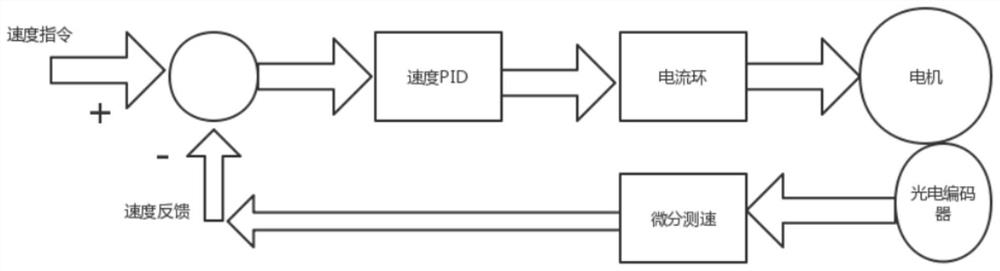

Image

Examples

Embodiment

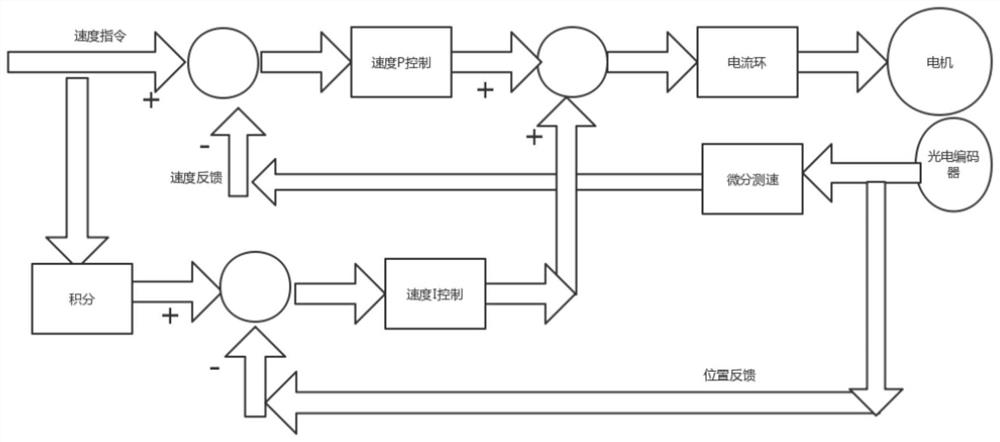

[0020] see figure 2 , the embodiment of the present invention provides a speed measurement system that can improve the speed control accuracy of an incremental photoelectric encoder, including an incremental photoelectric encoder, a differential speed measurement module, a speed command input terminal, a speed P control module, a current loop, a motor, Integral module and speed I control module. Wherein, one path of the incremental photoelectric encoder is sequentially connected to the input end of the motor through the differential speed measurement module, the speed P control module, and the current loop, and one path of the speed command input end is sequentially controlled by the speed P The module and the current loop are connected to the input end of the motor, and the speed P control module calculates the first torque command by using the speed feedback obtained by the differential speed measurement module and the speed command input by the speed command input end; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com