Acetic acid triethanolamine ester as well as preparation and application thereof

A technology of molar weight of triethanolamine ester and ethanolamine is applied in the preparation of organic compounds, the preparation of aminohydroxy compounds, organic chemistry, etc., and can solve the problems of high use cost, high price of triethanolamine, poor strength, etc., and achieves low cost and easy to use. Implementation, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation of embodiment 1 triethanolamine acetate

[0017] In a 500ml four-necked reaction flask, add 29.83g (0.20mol) of triethanolamine, 60.0ml (0.50mol) of xylene, 54.04g (0.90mol) of acetic acid, and 1.25g of sulfamic acid. After stirring evenly, heat the reaction flask and gradually Raise the temperature to 130°C-140°C, reflux and dehydrate until no more water comes out, change the reaction device to vacuum distillation, and distill out 57.5ml of xylene and 10.50g of unreacted acetic acid. After identification, the residue in the reaction bottle 62.30g is product of the present invention---triethanolamine acetate.

Embodiment 2

[0018] The preparation of embodiment 2 triethanolamine acetate

[0019] In a 1000ml four-necked reaction flask, add 82.93g (0.50mol, content 90.0%) of triethanolamine, 90.0ml (0.76mol) of xylene, heat to reflux, and remove 8.3g of water in triethanolamine; Add 90.1g (1.50mol) of acetic acid (1.50mol) and 5.0g of concentrated sulfuric acid to the medium, stir evenly, gradually raise the temperature to 120°C-130°C, reflux and dehydrate until no more water comes out, change the reaction device to vacuum distillation, and distill out Xylene 87.0ml, water and unreacted acetic acid 20.0g, after identification, residue 104.0g in the reaction bottle is the product of the present invention---triethanolamine acetate.

Embodiment 3

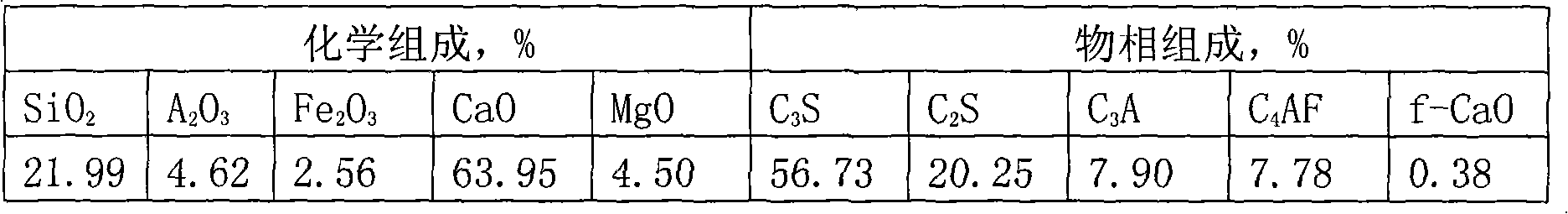

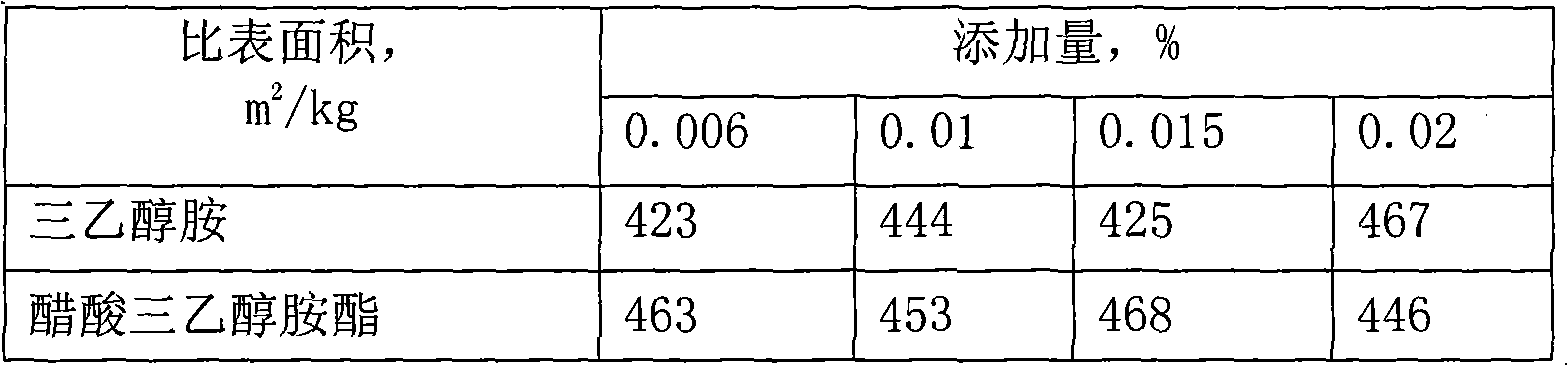

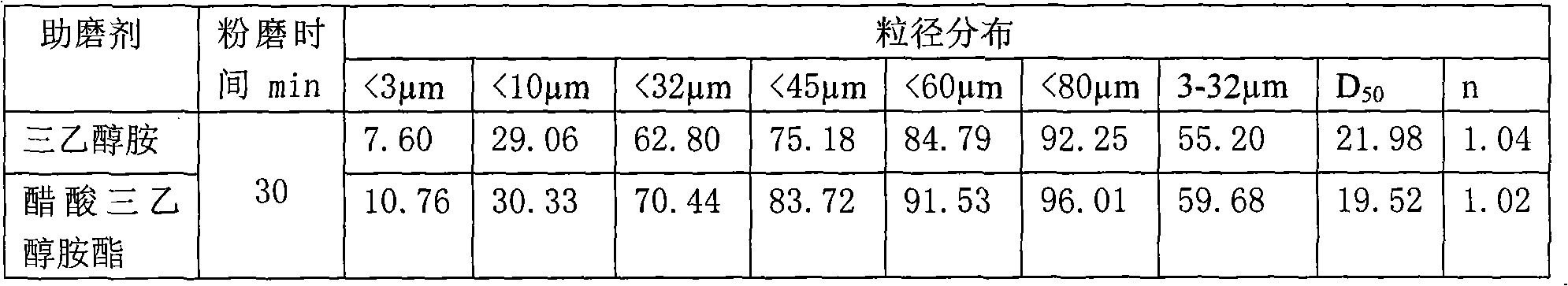

[0020] Example 3 Application of Triethanolamine Acetate in Cement Grinding Production as Cement Grinding Aid Strengthening Agent

[0021] The addition amount of triethanolamine acetate as a cement grinding aid is 0.01% of the total weight of cement, and the cement grinding production is carried out in a conventional manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com