Device and method for measuring thickness of molten slag layer of mold flux of continuous casting crystallizer

A continuous casting crystallizer and measuring device technology, applied in the field of steelmaking, can solve the problems of inaccurate measurement and large error of single-wire method and double-wire method, so as to eliminate human interference factors, improve accuracy and efficiency, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

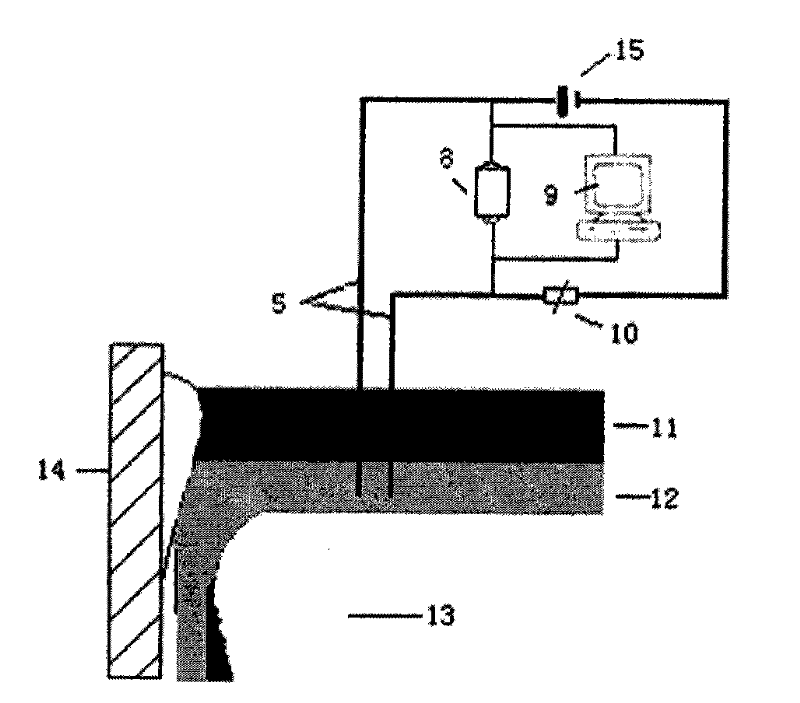

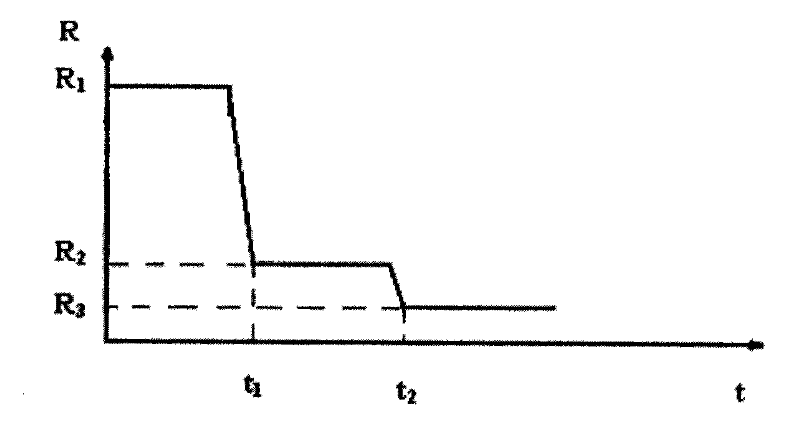

[0018] During the continuous casting production process, the mold slag closest to the molten steel 13 in the crystallizer 14 is melted into liquid slag, forming a molten liquid slag layer 12, and above the liquid slag layer 12 is an unmelted mold slag layer 11; studies have shown that the unmelted Mold slag layer 11 is incompletely melted, the number of ionized ions is small, and the resistance is large, usually reaching hundreds or even several megaohms. The liquid slag layer 12 is completely melted, almost completely ionized, and the resistance is very small, usually several ohms to tens of ohms. ohm, while molten steel 13 is generally regarded as a conductor, with a resistance of a few tenths of ohms; since the resistance between slag layers and between slag and molten steel is different, a conductivity electrode material with very small resistivity can be selected to measure the liquid slag layer. thickness.

[0019] Concrete implementation steps of the present invention a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com