Silicon-based vapor-liquid phase separating heat radiation chip and preparation method thereof

A phase separation, vapor-liquid technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of complex radiator structure, unfavorable miniaturization, unfavorable environmental protection, etc., and achieve simple structure, convenient manufacture, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

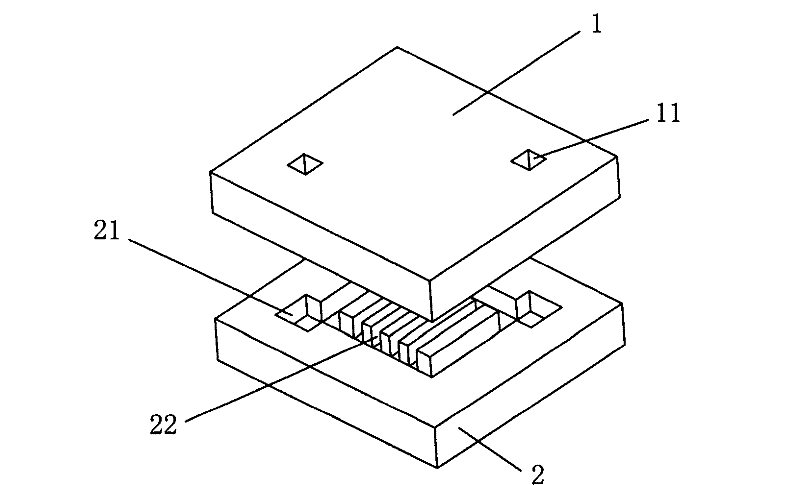

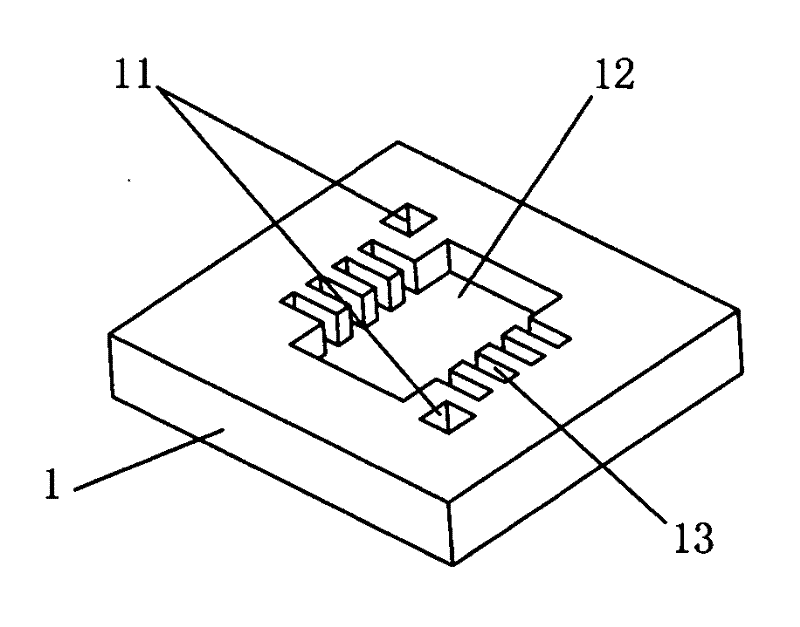

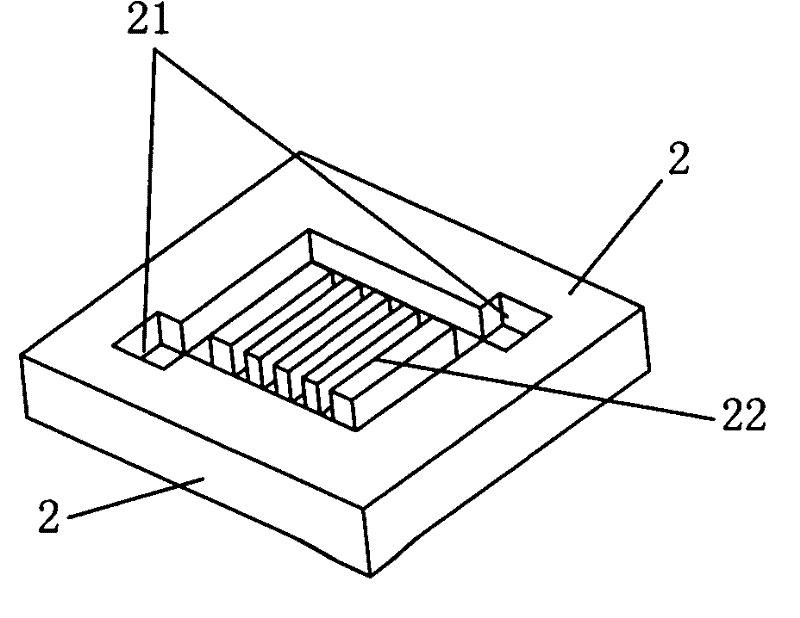

[0062] see Figure 1~3 , the silicon-based vapor-liquid phase separation heat dissipation chip of the present invention has an upper and lower two-layer structure, which are respectively an upper silicon chip and a lower silicon chip, and the upper silicon chip 1 is provided with a cooling liquid loading port 11, a liquid vaporization chamber 12 and a gas The microchannel 13, the liquid vaporization chamber 12 is arranged in the middle of the upper silicon chip 1, the gas microchannel 13 is arranged on the outside of the liquid vaporization chamber 12 and communicates with the gas microchannel 13, and the cooling liquid loading port 11 is arranged on both sides of the liquid vaporization chamber 12; The lower silicon chip 2 is provided with a cooling liquid storage tank 21 and a liquid microchannel 22, and the liquid microchannel 22 is arranged in the cooling liquid storage tank 21; the upper silicon chip and the lower silicon chip are formed by aligning and bonding silicon-sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com