Track for high-temperature super-conductivity magnetic levitation transport system

A transportation system and high-temperature superconducting technology, which is applied in transportation and packaging, electric traction, electric vehicles, etc., can solve the problems of inner magnetic field strength enhancement, waste, and cost increase, so as to achieve stable and reliable operation and avoid eccentricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

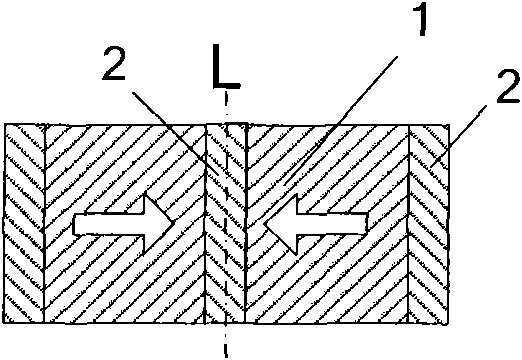

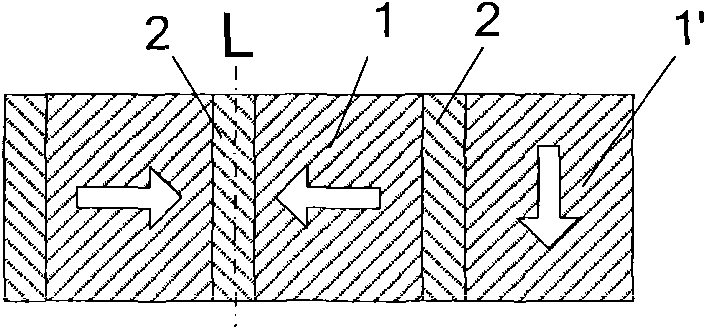

[0033] Figure 1a , 1b , 2a, 2b and Figure 7 It is shown that a specific embodiment of the present invention is: a high-temperature superconducting maglev transportation system track, the track is symmetrically distributed with permanent magnets 1 and magnetic poles 2 on both sides of the reference line L, and the curved part of the track is on the reference line L A row of auxiliary permanent magnets 1' is added laterally on the outside of the

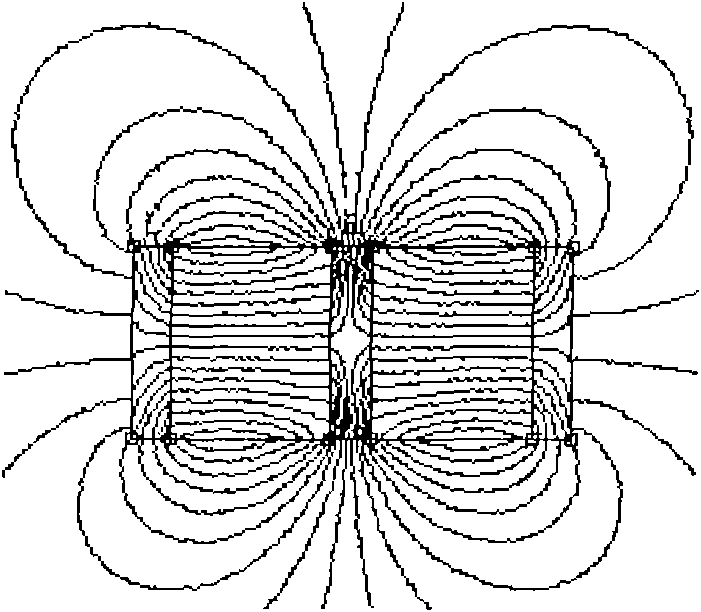

[0034] Figure 1a It can be seen that the straight part of this example has the same structure as a translational symmetric magnetic levitation track currently used, and its permanent magnets are symmetrically distributed on both sides of the reference line L of the track. Figure 1b It can be seen that the magnetic field distribution in the straight part of the track is symmetrically distributed on both sides of the reference line.

[0035] Figure 1a with Figure 2a It is also shown that the magnetization direction of each colum...

Embodiment 2

[0039] Figure 1a , 1b , 3a, 3b show that this embodiment is basically the same as Embodiment 1, the only difference is that two rows of auxiliary permanent magnets 1' are added laterally outside the reference line in the curved part of the track, and the added auxiliary permanent magnets 1' are In the third and fourth columns, the magnetization directions are downward and to the right in turn.

[0040] from Figure 3bIt can be seen that after adding two columns of auxiliary permanent magnets 1' in this example, the horizontal strong magnetic field area outside the reference line L is expanded, so that the magnetic field is asymmetrically distributed to the reference line L. Compared with the inner (left) side, the area outside the reference line L The magnetic field increases on the (right) side. and, from Figure 3b It can also be seen that a magnetic potential well composed of three magnetic force line convex peaks is formed above the track in this example, and the two s...

Embodiment 3

[0043] Figure 4a , 4b , 5a, and 5b show that the third specific embodiment of the present invention is: a high-temperature superconducting maglev transportation system track, and the track has permanent magnets 1 and magnetic gathering poles 2 symmetrically distributed on both sides of the reference line L. A row of auxiliary permanent magnets 1' is added laterally on the outside of the reference line in the curved part of the track.

[0044] In this example, the magnetization direction of each column of permanent magnets is: from the inner (left) side, the first column is right, the second column is upward, the third column is left, and the fourth column is the auxiliary permanent magnet 1 ' added at the bend. Its direction is downward.

[0045] Figure 4a It can be seen that the permanent magnets in the straight part of this example are symmetrically distributed on both sides of the reference line L of the track. Figure 4b It can be seen that the magnetic field distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com