Method for modifying paper filler-calcium carbonate

A paper-making filler and calcium carbonate technology, which is applied in the direction of fibrous filler, inorganic compound addition, dyeing polymer organic compound treatment, etc., can solve problems such as price and technical problems, adverse effects of starch layer stability on paper making, and difficulty in application. Achieve the effects of increasing the dosage range, simple modification method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] PCC: Precipitated calcium carbonate, also known as light calcium carbonate, a product of Niangziguan Chemical Factory, Pingding County, Hebei Province, China.

[0029] Modifier: Microemulsion cationic styrene-acrylate emulsion made in the laboratory.

[0030] Quality index of styrene-acrylic ester: the appearance is milky white liquid; the solid content is 25%.

[0031] A modification method of paper-making filler calcium carbonate, described calcium carbonate is precipitated calcium carbonate (PCC), and its modification method comprises the following steps: one), the preparation of PCC dispersion liquid; Two), control PCC and cationic styrene -Acrylic acid ester emulsion reaction condition; 3), obtain modified PCC after cooling precipitation, concrete operation is as follows:

[0032] 1) Preparation of PCC dispersion: Add PCC to water, heat in a water bath at 80°C-90°C and fully stir with a multifunctional stirrer, so that the temperature of the PCC dispersion reaches...

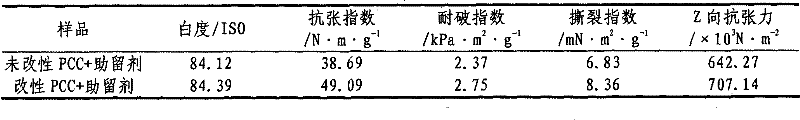

Embodiment 2

[0043] A modification method of paper-making filler PCC, the operation steps in the method, various parameters, the mass ratio of PCC to cationic styrene-acrylic acid ester, the embedding rate and binary retention aid cationic polyacrylamide, the amount of cationic starch added and The hand-sheet method is the same as in Example 1, and the amount of modified PCC added is increased to 35% (based on dry pulp). The detection method of the hand-sheet physical properties is the same as in Example 1, and the test results are shown in Table 2.

[0044] Table 2

[0045]

[0046] In quantitative 80g / m 2 In the paper, adding 35% unmodified PCC (based on dry pulp), the ash content of the paper is 17.88%, while adding the same amount of modified PCC, the ash content of the paper is 23.73%.

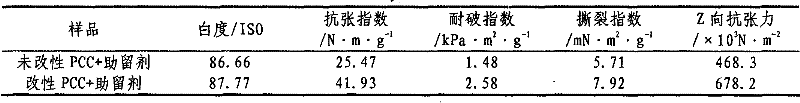

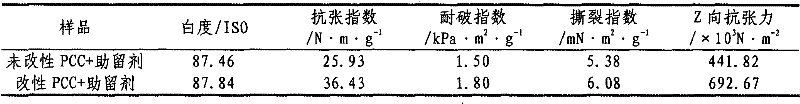

Embodiment 3

[0048] A modification method of paper-making filler PCC, the operation steps in the method, various parameters, the mass ratio of PCC to cationic styrene-acrylic acid ester, the embedding rate and binary retention aid cationic polyacrylamide, the amount of cationic starch added and The hand-sheet method is the same as in Example 1, and the amount of modified PCC is increased to 40% (based on dry pulp). The detection method of the physical properties of the hand-written sheet is the same as in Example 1, and the detection results are shown in Table 3.

[0049] table 3

[0050]

[0051] In quantitative 80g / m 2 In the paper, adding 40% unmodified PCC (based on dry pulp), the ash content of the paper is 20.52%, while adding the same amount of modified PCC, the ash content of the paper is 26.78%.

[0052] Through a series of studies, the inventors of the present invention found that modified PCC was prepared by embedding PCC with cationic styrene-acrylate. Modified PCC is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com