Face plate rock-fill dam structure of reasonably utilizing sand gravel material and construction method thereof

A face rockfill dam and rockfill dam technology, applied in dams, barrages, barrages, etc., can solve the problems of increasing dam filling volume and project investment, poor seepage stability of sand and gravel materials, construction progress, and difficulty effects, etc. , to achieve the effect of reducing dam settlement, avoiding cushion cracking, and reducing filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

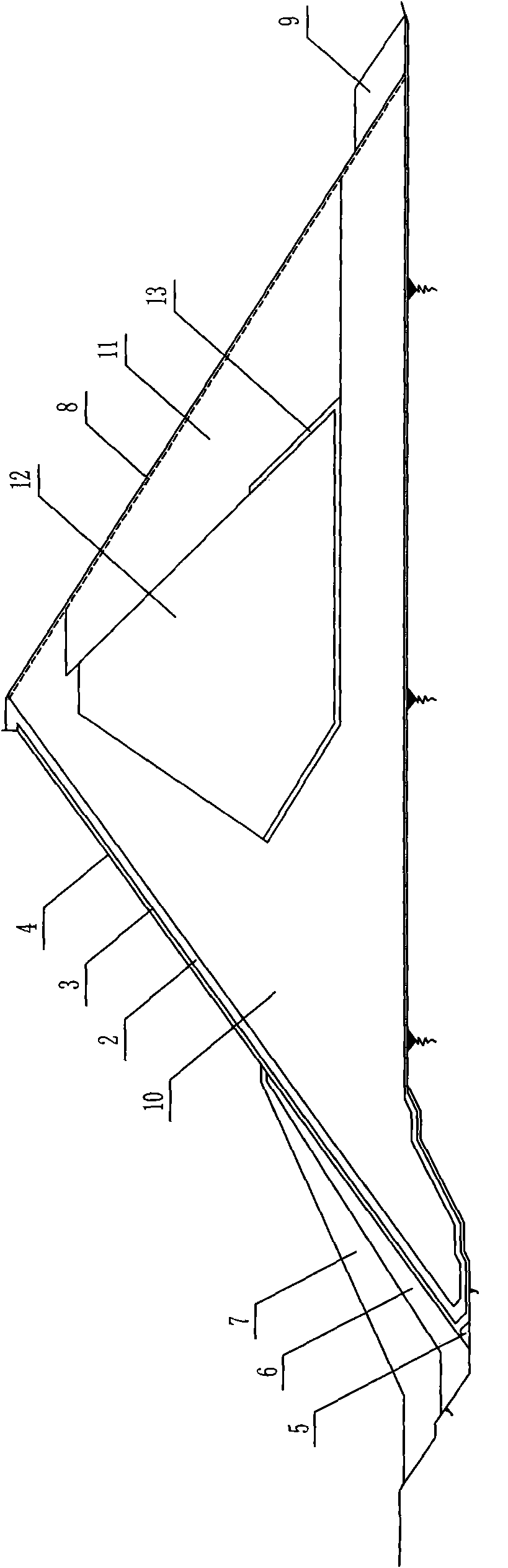

[0019] Such as figure 1 As shown, this embodiment has a rockfill dam main body, and its upstream side is laid with a transition layer, a cushion layer and a face plate 4 sequentially from the inside to the outside, wherein a special cushion layer 5 is set under the cushion layer 3, and gravel slag backfill is set at the dam foundation on the upstream side of the main body Area 6 and silt backfill area 7, dry masonry slope protection 8 is set on the downstream side of the main body, and an over-diameter stone pressure slope area 9 is set on the downstream dam foundation. The main body includes a main rockfill area 10 and a secondary rockfill area 11 on the downstream side , The gravel area 12 located above the dam soaking line is set in the cavity surrounded by the two to coordinate the balance of earthwork excavation and filling, thereby avoiding the need to open up a rockfill yard, effectively protecting the ecological environment and saving engineering investment. At the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com