Ring-shaped gasification liquid fuel high-heat energy saving burner

A liquid fuel and burner technology, applied in the directions of burners, combustion methods, combustion types, etc., can solve the problems of poor gasification effect of the gasification chamber of the burner, insufficient oxygen supply to the burner, unacceptable to users, etc. The effect of fully, eliminating the phenomenon of red fire and eliminating hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

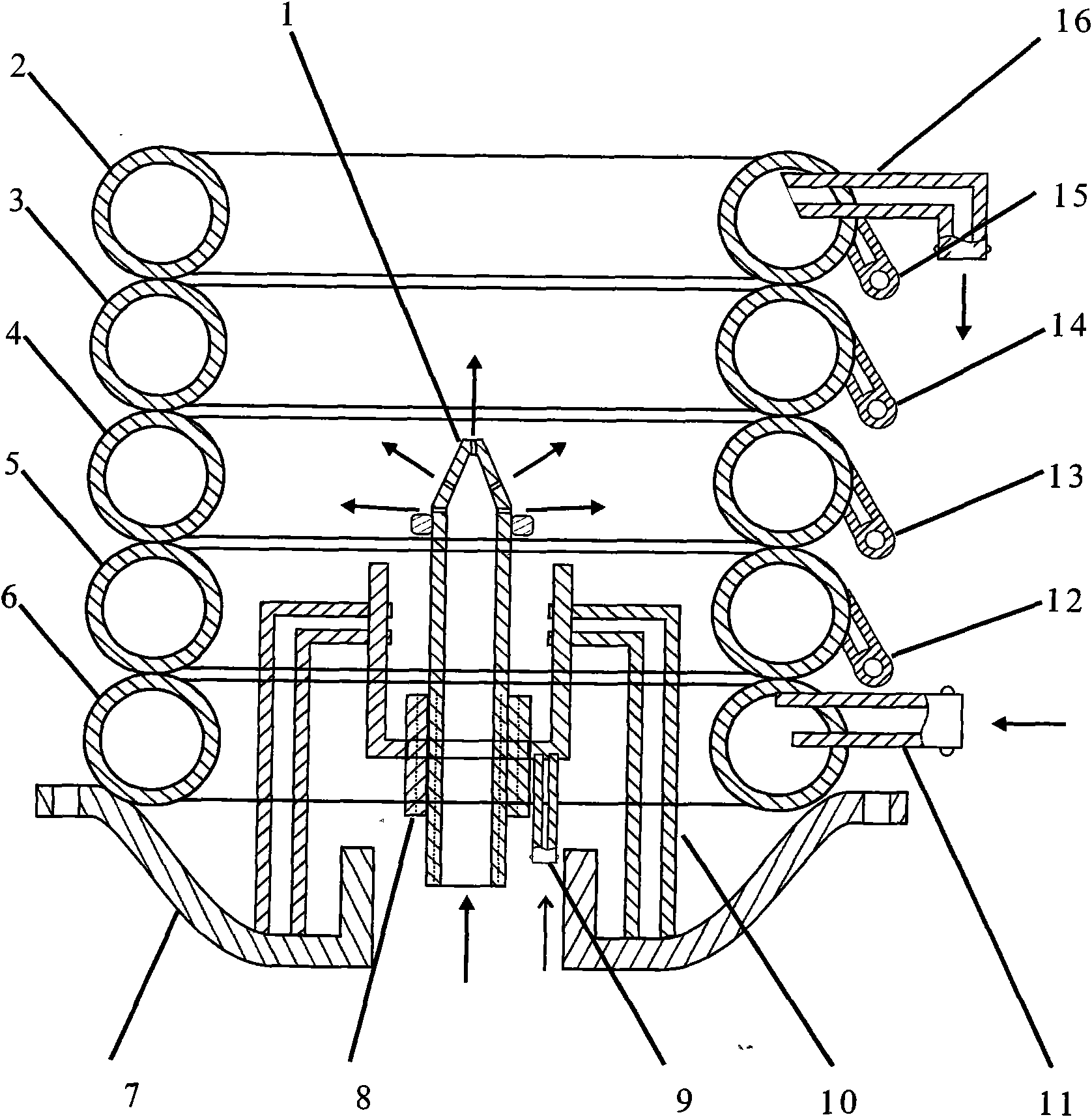

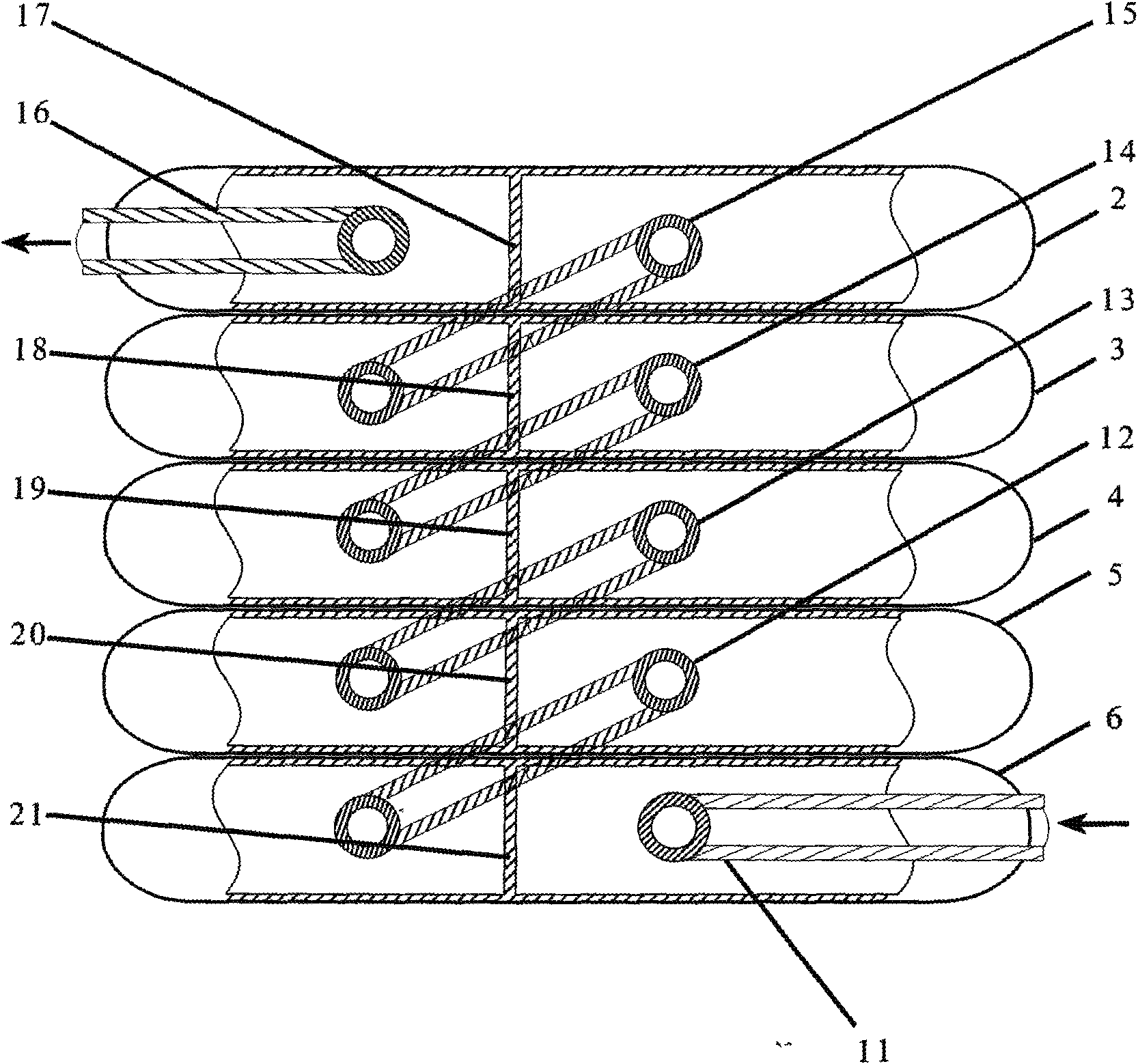

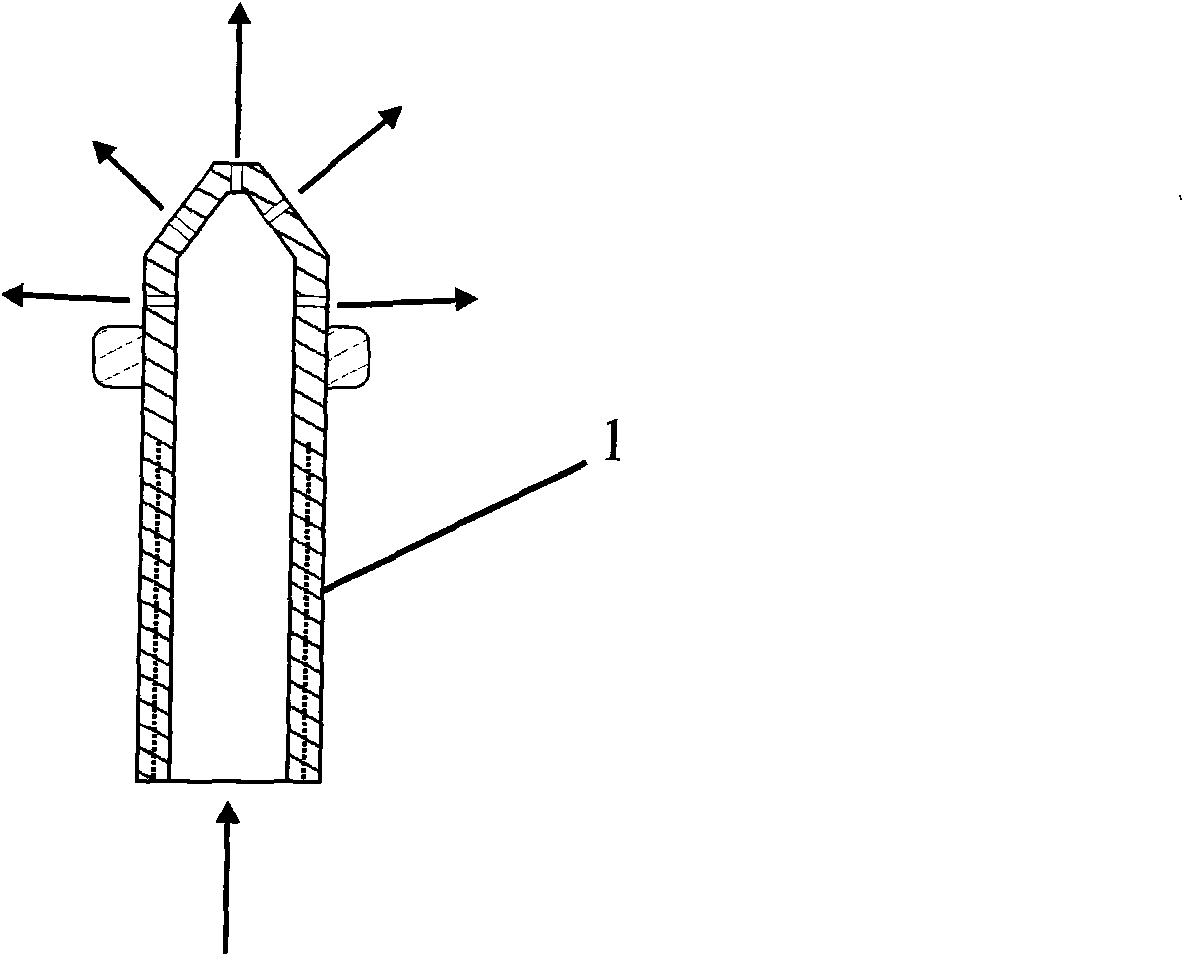

[0015] see Figure 1 to Figure 5 , an annular gasified liquid fuel high-fire energy-saving burner of the present invention, including a nozzle fire distributor 1, a gasification chamber 2, a gasification chamber 3, a gasification chamber 4, a gasification chamber 5, a gasification chamber 6, and a preheating plate 7. Central burner 8, central burner feed pipe 9, central burner distribution pipe 10, gasification chamber feed pipe 11, gasification chamber connecting pipe 12, gasification chamber connecting pipe 13, gasification chamber connecting pipe 14. Gasification chamber connection pipe 15, gasification chamber gas outlet pipe 16, the key point is that the gasification chamber connecting body 2-6 is an annular pipe, and a gasification chamber partition 17-21 is arranged inside the annular pipe. A gasification chamber feed pipe 11 has been stretched into one side of the partition plate 21 of the gasification chamber 6, and the length of its insertion is greater than or equal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap