Spray gun for plasma physical vapor deposition and preparation method of thermal barrier coating

A physical vapor deposition and plasma technology, applied in coating, ion implantation plating, metal material coating process, etc., can solve problems such as anode burn-through, unstable arc ignition, and inability to gasify powder, so as to increase the negative and positive The effect of inter-electrode distance, reduction of production cost, and reduction of current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

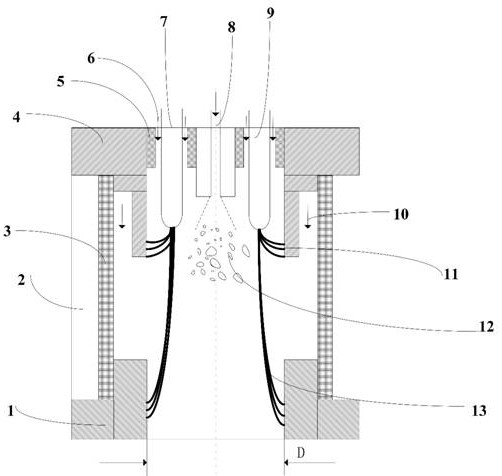

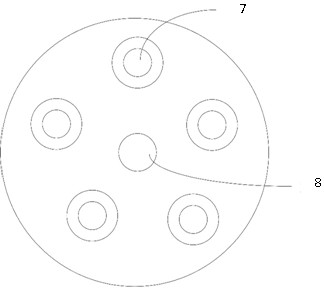

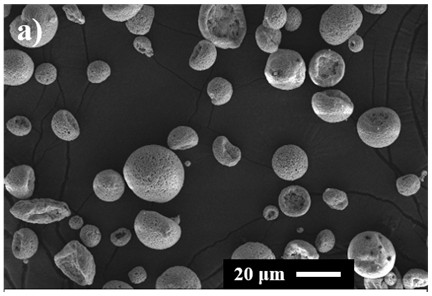

[0068] Using a five-cathode high-efficiency and low-cost plasma torch, the top view is as follows figure 2 As shown in the figure, the symmetrically distributed hollow water-cooled cathode and the powder feeding tube located on the central axis are selected as the working gas for arc ignition, and Ar and H are selected as the working gas when the arc is stable. 2 gas mixture. The spray gun was installed on the plasma physical vapor deposition equipment, and the YSZ powder was agglomerated and granulated. The powder D50 was 10-20 μm, and the powder morphology was spherical, such as Figure 3a shown,

[0069] The specific spraying steps are as follows:

[0070] Step 1: Close the vacuum chamber and evacuate so that the pressure of the vacuum chamber is lower than 0.08 mbar;

[0071] Step 2: Fill with Ar gas until the vacuum chamber pressure reaches 130 mbar;

[0072] Step 3: start the arc, start the arc between the hollow water-cooled cathode and the auxiliary anode at a low...

Embodiment 2

[0081] A three-cathode spray gun of the present invention is installed on the plasma physical vapor deposition equipment, and the columnar structure coating is prepared by using the ungranulated nano-powder, the nano-powder D50 is 0.5-1 μm, and the powder is irregular in shape, such as: Figure 4a shown. The specific spraying steps are as follows:

[0082] Step 1: Close the vacuum chamber and evacuate, so that the pressure of the vacuum chamber is lower than 0.08mbar;

[0083] Step 2: Fill with Ar gas until the vacuum chamber pressure reaches 130mbar;

[0084] Step 3: striking the arc, starting the arc between the hollow water-cooled cathode and the auxiliary anode at a low current of 30A and an Ar gas flow of 15L / min;

[0085] Step 4: Lengthen the plasma arc, after the plasma arc is stable, increase the current between the hollow water-cooled cathode and the water-cooled anode to 65A, adjust the Ar flow to 30L / min, H 2 The air flow is 30L / min, and the plasma arc is transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com