Parallel stream heat exchanger integrated with microchannel and outer fin

A technology of parallel flow heat exchanger and microchannel, which is applied in the direction of heat exchange equipment, evaporator/condenser, lighting and heating equipment, etc., which can solve the complex processing of the shell connected to the heat sink, the increase of refrigerant flow resistance, The processing process is cumbersome and other problems, to achieve the effect of reducing material cost, increasing heat transfer, and eliminating contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be noted that the protection scope of the present invention is not limited to the scope described in the embodiments.

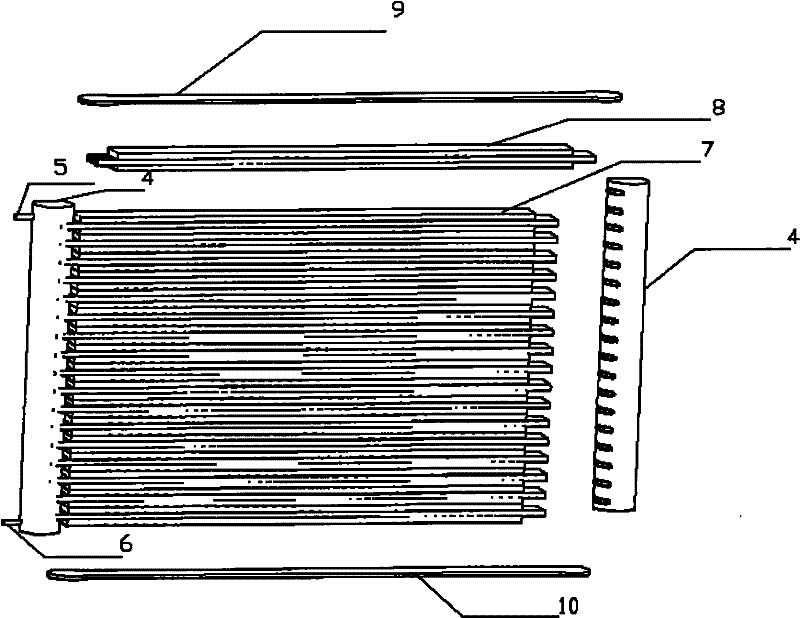

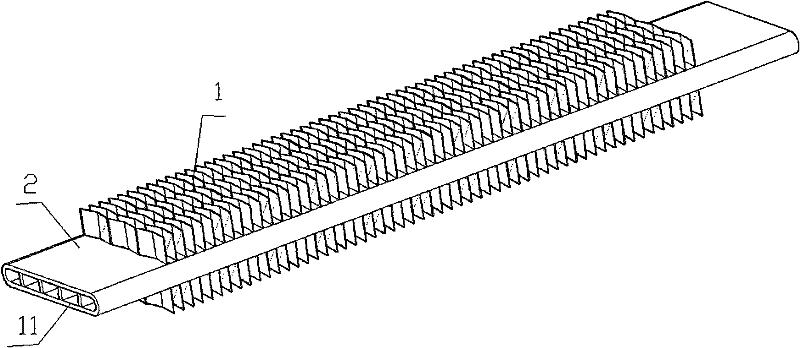

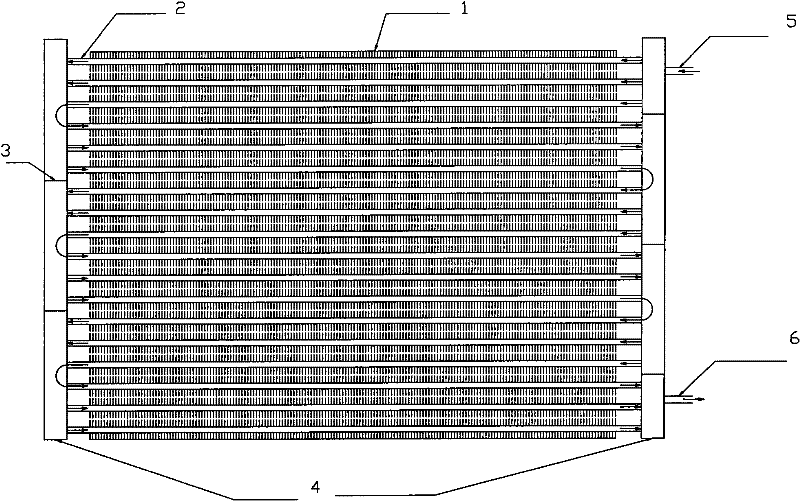

[0026] Such as Figure 1~3 As shown, a parallel flow heat exchanger in which microchannels and outer fins are integrally formed includes left and right liquid collecting pipes 4, an upper cover plate 9, a lower cover plate 10, a cooling fin group 7, an air inlet pipe 5 and a liquid outlet pipe 6; The heat sink group 7 is formed by connecting multiple heat sinks 8 side by side, and is located in the frame structure composed of the upper cover plate 9, the lower cover plate 10 and the left and right liquid collection pipes 4; the heat sink 8 is composed of fins 1 and aluminum profiles 2. Forming, there are micro-channels 11 on the aluminum profile, and the micro-channels 11 have several shapes of circle, rectangle and ellipse. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com