Steel plate with high strength and low yield ratio

A low-yield ratio, high-strength technology, applied in the field of iron and steel materials, can solve the problems of complex chemical composition, low strength, and increased raw material costs, and achieve the effect of simple production process, low cost, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

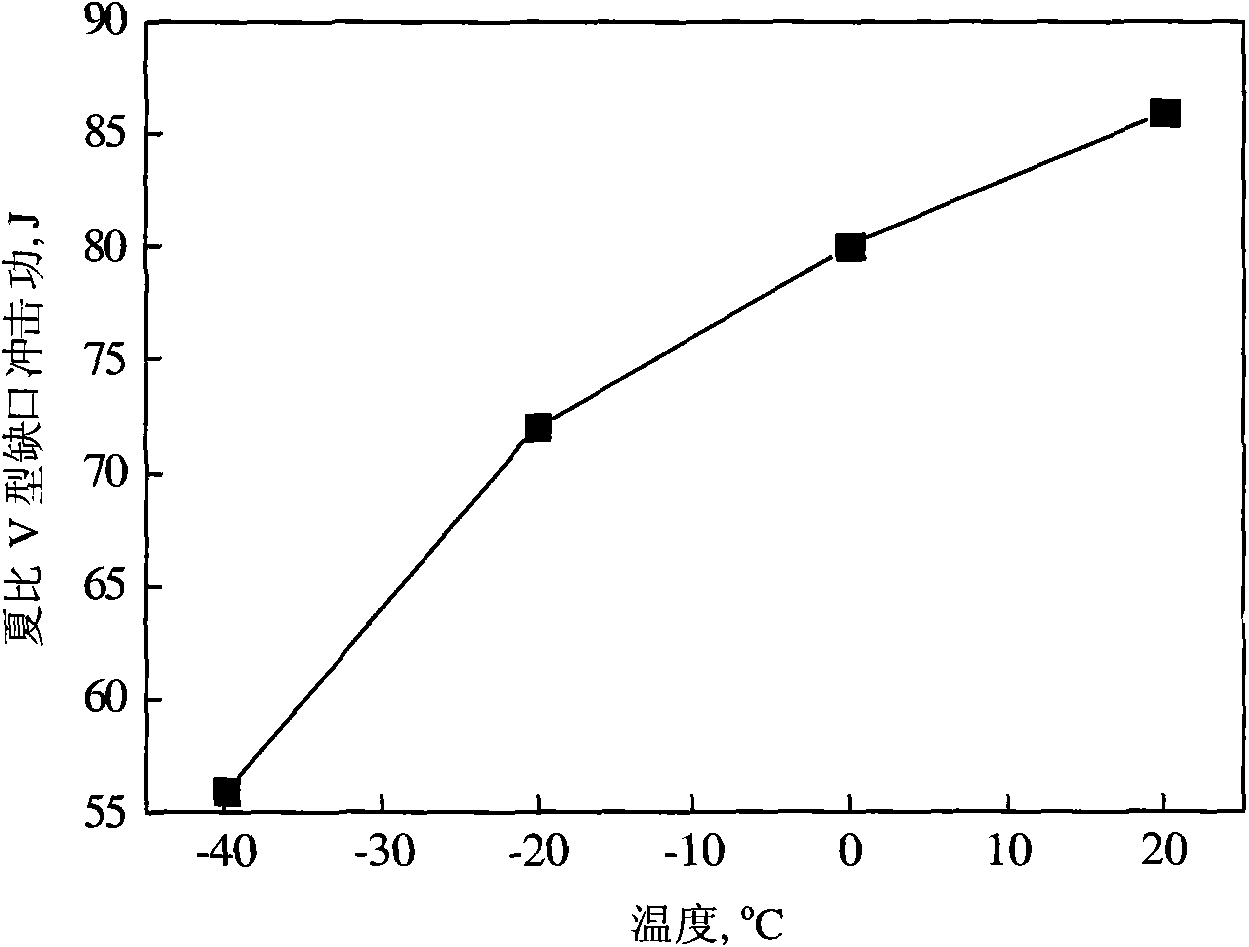

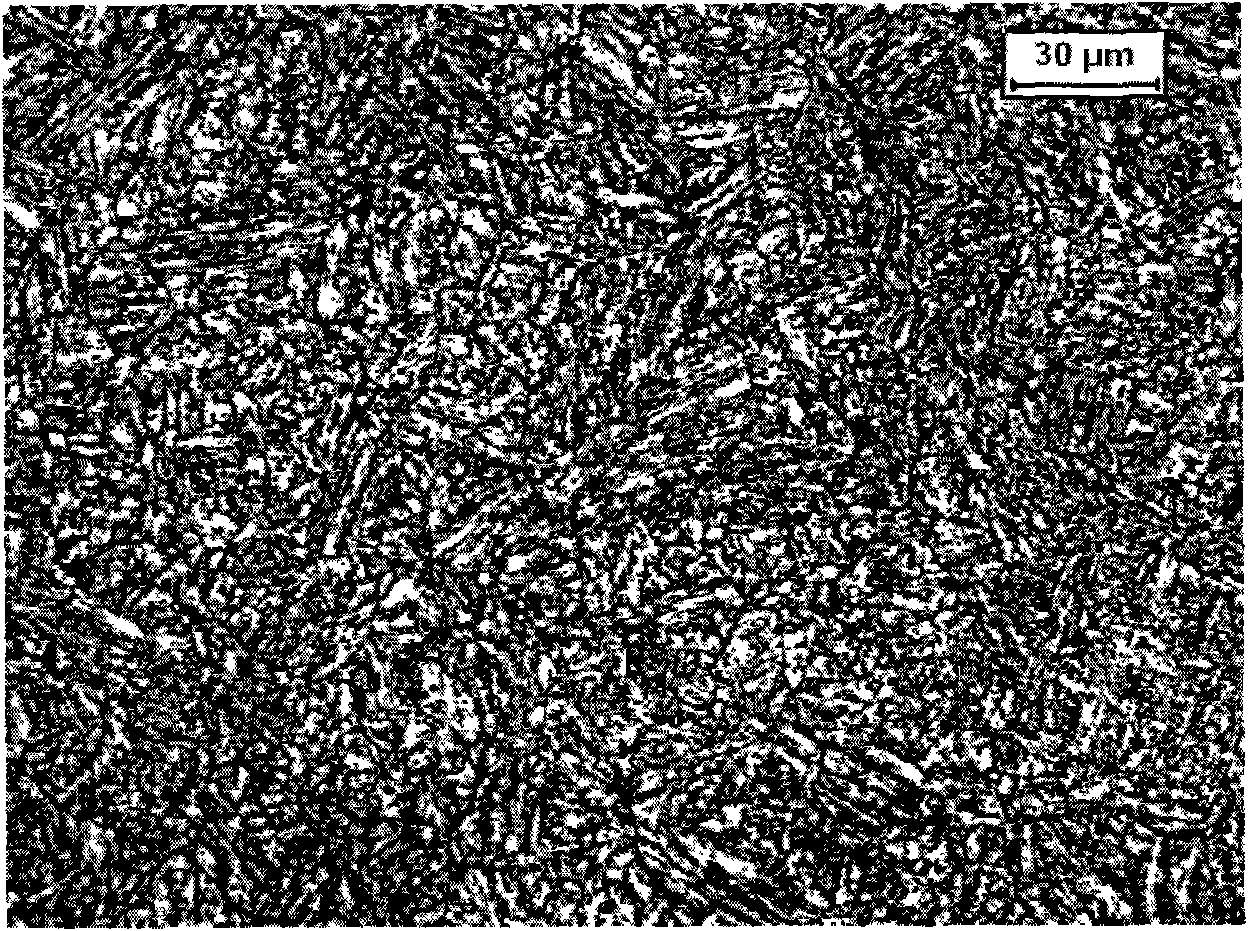

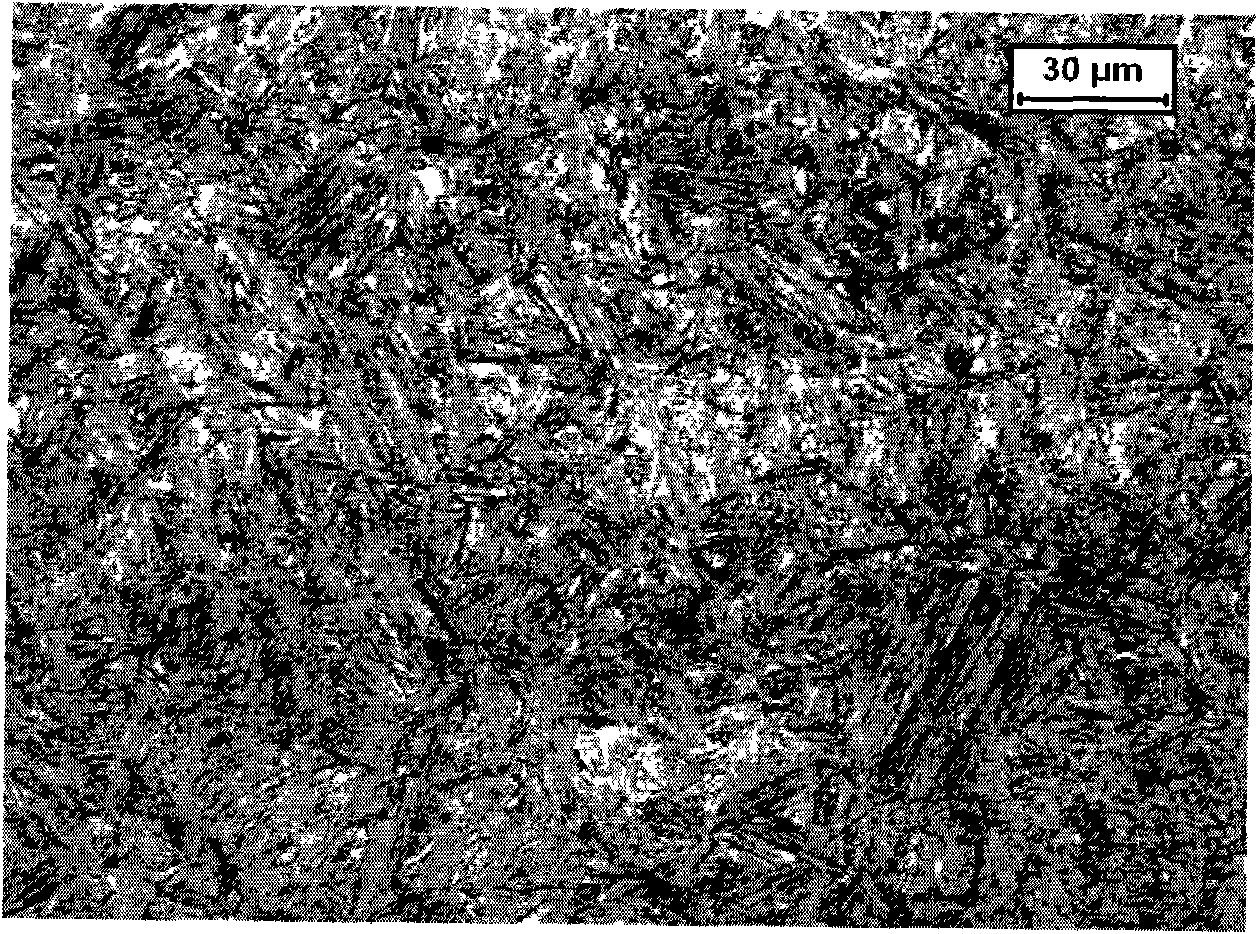

Examples

Embodiment 1

[0027] According to the chemical composition shown in Table 3, the molten steel is smelted in a converter or an electric furnace, and then secondarily refined in a vacuum furnace, and cast into a billet (ingot) with a thickness of 220 mm. The billet (ingot) is heated to 1200 ° C and kept for 1 to 2 hours. Then rolling, the starting rolling temperature is 1000-1070°C, the rolling thickness is 120-220mm, the cumulative deformation above 950°C is ≥50%, the intermediate billet is heated at about 1000°C to 900°C, and the final rolling temperature is 800- 850°C, the thickness of the steel plate is 100mm, water cooling is carried out at a speed of 8-10°C / s after rolling, and the final cooling temperature is 500-550°C.

Embodiment 2

[0029] Except that the billet (ingot) heating temperature is 1200° C. and the thickness of the steel plate is 40 mm, other implementations are the same as in Example 1.

Embodiment 3-5

[0031] Except that the billet (ingot) heating temperature is 1150° C. and the thickness of the steel plate is 80 mm, other implementations are the same as in Example 1.

[0032] Table 3 Chemical composition (wt %) of the steel plate of embodiment 1-5 of the present invention

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com