Method for producing a three-dimensional object by means of laser sintering

A technology for three-dimensional objects and objects, which is applied in the direction of processing and manufacturing, solid material additive processing, additive processing, etc., can solve problems such as the inability to eliminate layer coating defects in a targeted manner, and the impossibility of accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

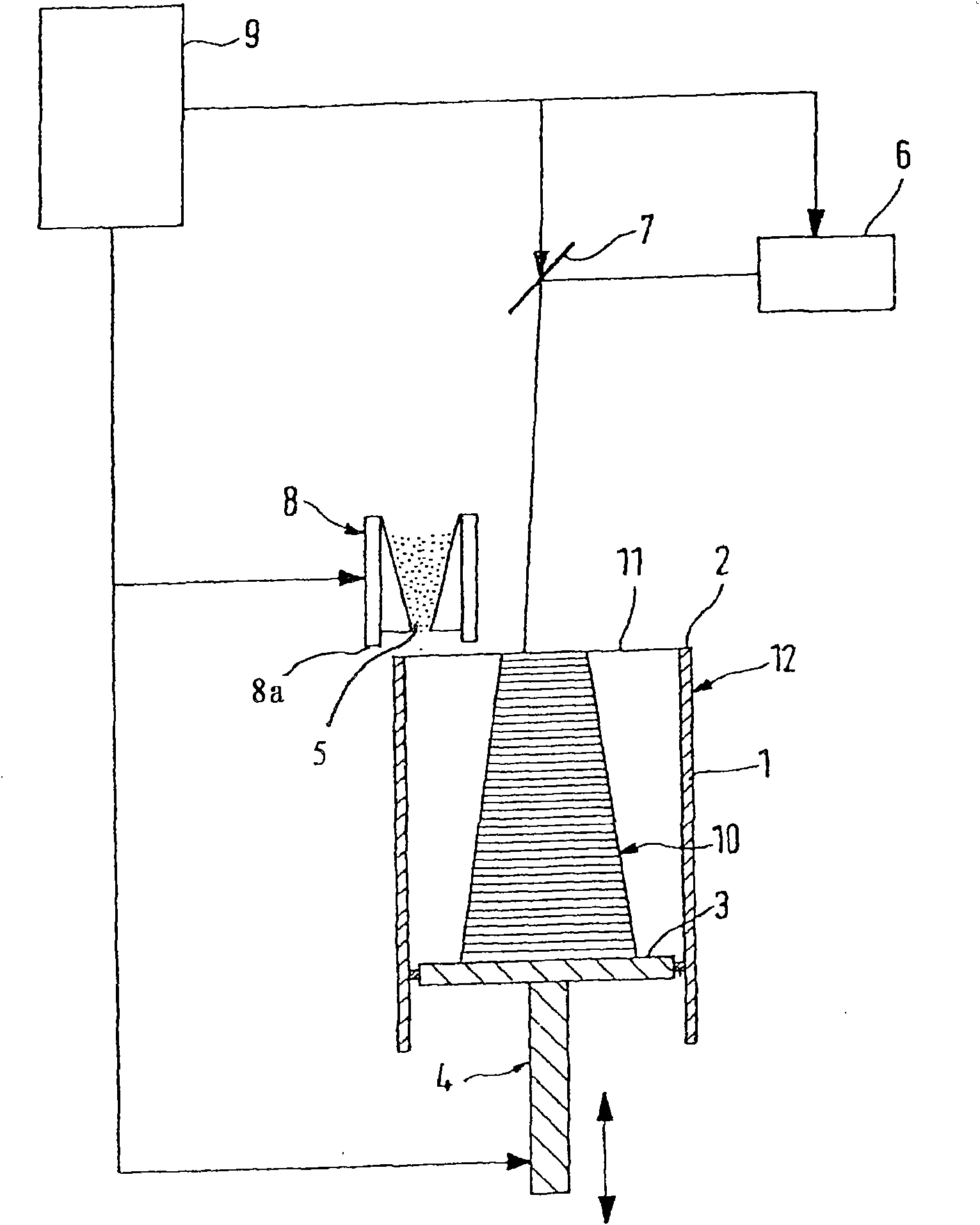

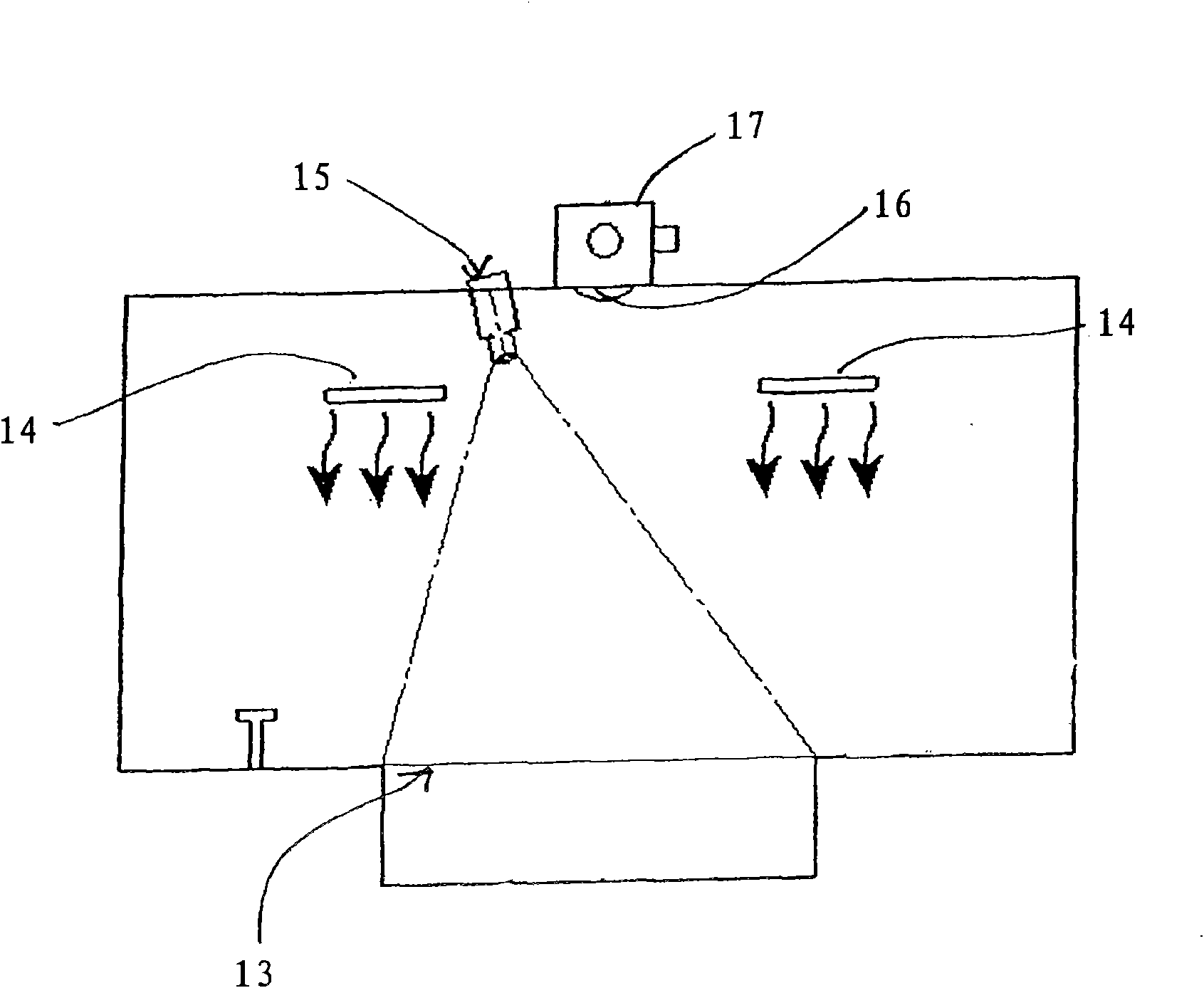

[0017] as from figure 1 As can be seen most clearly, the laser sintering device according to the invention has an upwardly and downwardly open structural frame 1 with an upper edge 2 . A structural platform 3 is arranged in the structural frame, and the structural platform is connected with a vertical transmission device 4, through which the structural platform can move up and down in the vertical direction. A hardening device in the form of a laser 6 and a beam deflection system 7 is arranged above the upper edge 2 . Furthermore, there is an applicator 8 for applying powdery material. The applicator comprises, for example, a container extending transversely over the processing area, which can be filled with a reserve powder and has a discharge opening 5 extending transversely over the processing area on its bottom face. Furthermore, the spreader usually has at least one blade 8 a for producing a powder layer with a predetermined thickness. The laser 6 , the beam deflectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com