Electronic product window and manufacturing method thereof and electronic product

A technology for electronic products and production methods, which is applied to electrical equipment casings/cabinets/drawers, electrical components, identification devices, etc., can solve the problems of fragility, single appearance effect, weak pressure resistance, etc., and achieves improved quality and novel appearance. unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

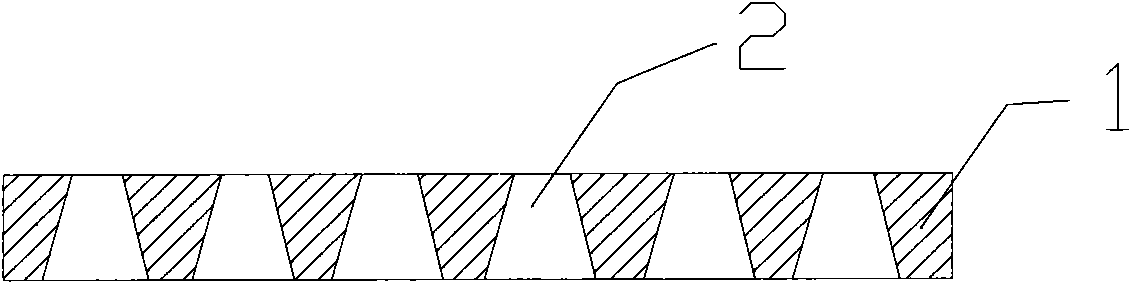

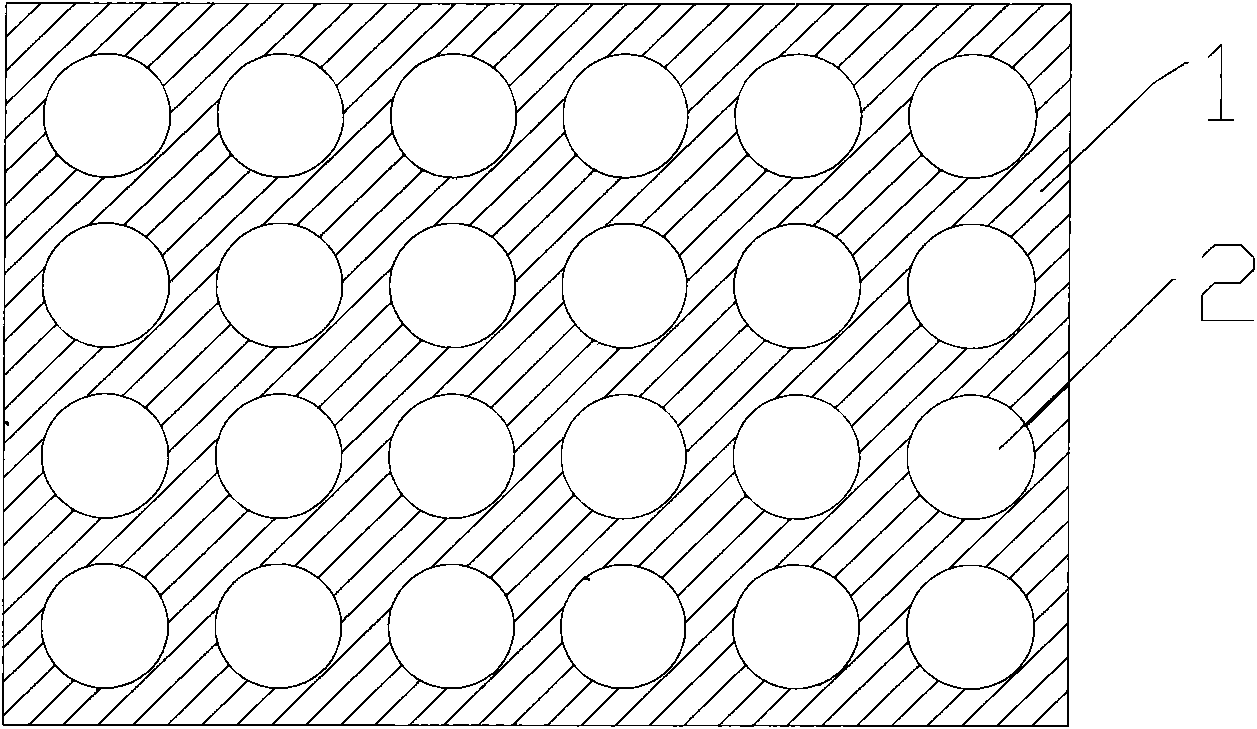

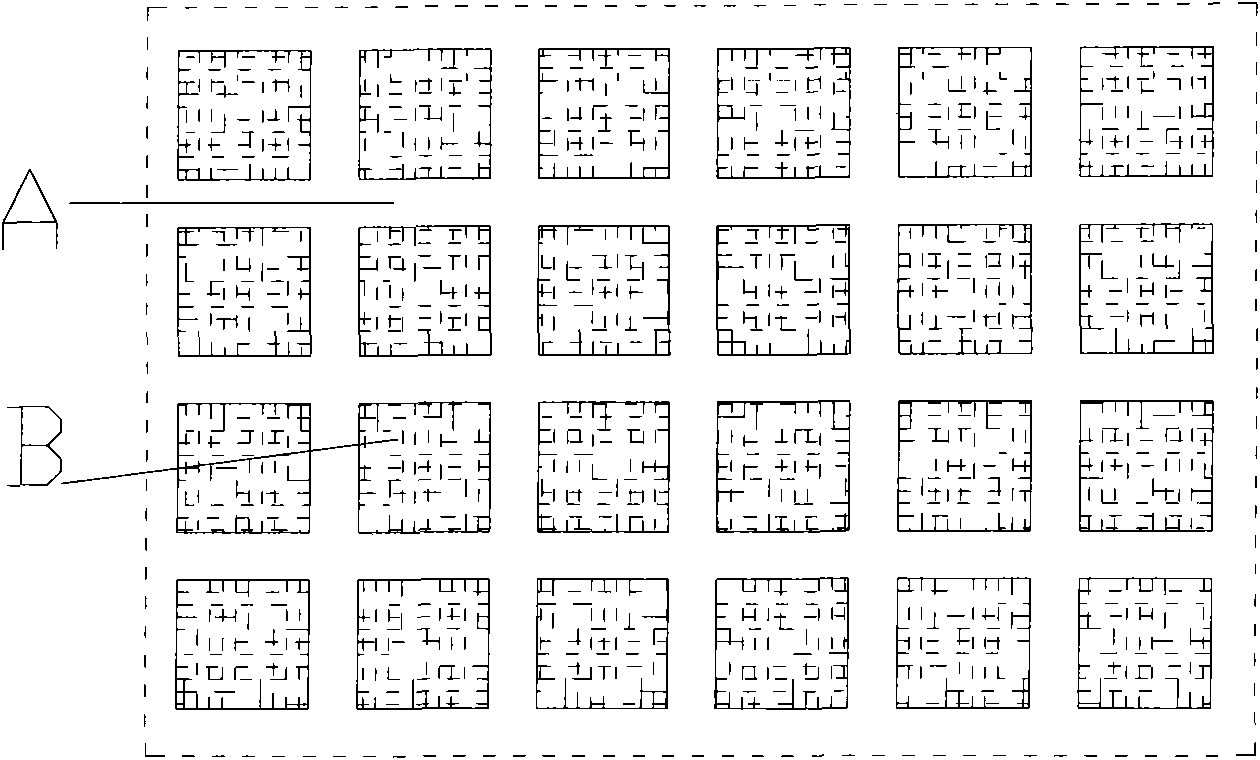

[0042] This example illustrates the preparation method of the electronic product window provided by the present invention.

[0043] An aluminum alloy plate with a thickness of 0.15 mm was selected and laser cutting was used to process the contour of the window substrate to obtain a window substrate with a size of 2.0 inches. Fiber laser drilling machine (YLP-20 laser drilling machine produced by Han’s Laser, the laser drilling power is 10 watts, the speed is 400 mm / s, the frequency is 20K Hz, and the focusing lens is 100 mm), Through-hole processing is performed on an aluminum alloy substrate (mobile phone window) with a thickness of 0.15 mm. Start blowing nitrogen or argon inert gas protection at the beginning of laser drilling, and stop blowing until the drilling is completed. A window having through-holes arranged in a matrix with an apparent face diameter of 0.05 mm and a hole pitch of 0.06 mm was obtained. Then the substrate was cleaned with dilute hydrochloric acid for...

Embodiment 2

[0046] This example illustrates the preparation method of the electronic product window provided by the present invention.

[0047] An aluminum alloy plate with a thickness of 0.25 mm is selected, and the contour of the window substrate is processed by laser cutting to obtain an aluminum alloy window substrate with a size of 2.0 inches. Then use a fiber laser drilling machine (the model YLP-20 laser drilling machine produced by Han’s Laser, the laser drilling power is 13 watts, the speed is 300 mm / s, the frequency is 20K Hz, and the focusing lens is 100 mm) , Through-hole processing is performed on an aluminum alloy substrate (mobile phone window) with a thickness of 0.25 mm. Start blowing nitrogen or argon inert gas protection at the beginning of laser drilling, and stop blowing until the drilling is completed. A window having through-holes arranged in a matrix with an apparent face diameter of 0.05 mm and a hole pitch of 0.06 mm was obtained. Then the substrate was cleaned...

Embodiment 3

[0050] This example illustrates the preparation method of the electronic product window provided by the present invention.

[0051] A stainless steel plate with a thickness of 0.15 mm was selected, and the contour of the window substrate was processed by laser cutting to obtain a stainless steel window substrate with a size of 2.0 inches. Fiber laser drilling machine (YLP-20 laser drilling machine produced by Han’s Laser, the laser drilling power is 13 watts, the speed is 300 mm / s, the frequency is 20K Hz, and the focusing lens is 100 mm), Through-hole processing is performed on a stainless steel substrate (mobile phone window) with a thickness of 0.15 mm. Start blowing nitrogen or argon inert gas protection at the beginning of laser drilling, and stop blowing until the drilling is completed. A window having through-holes arranged in a matrix with an apparent face diameter of 0.12 mm and a hole pitch of 0.13 mm was obtained. Then the substrate was cleaned with dilute hydroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com