Steel plate exhibiting excellent bendability by line heating and process for production of the plate

A bending workability, linear heating technology, applied in the direction of manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., can solve problems such as cost increase, and achieve the effects of cost reduction, increase in bending deformation, and reduction in energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

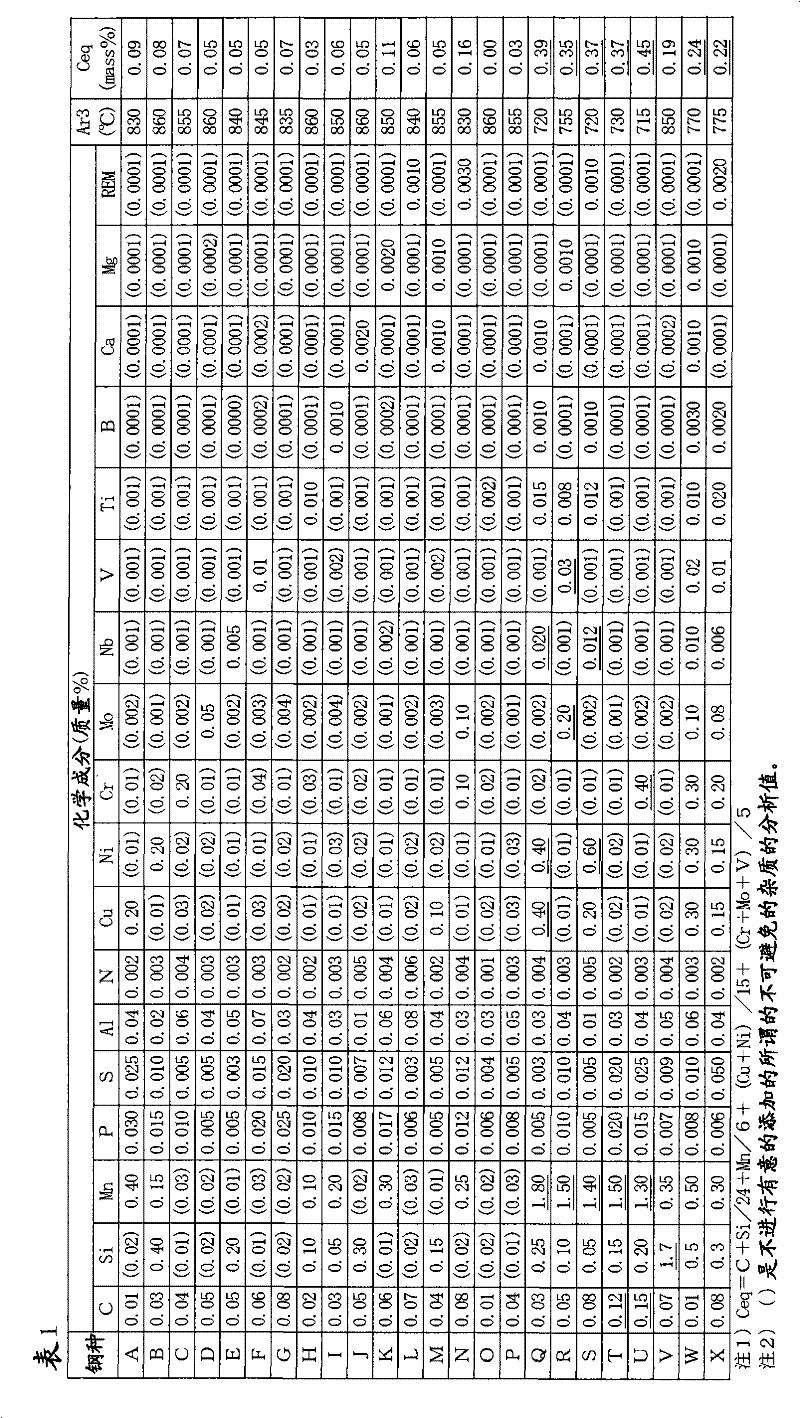

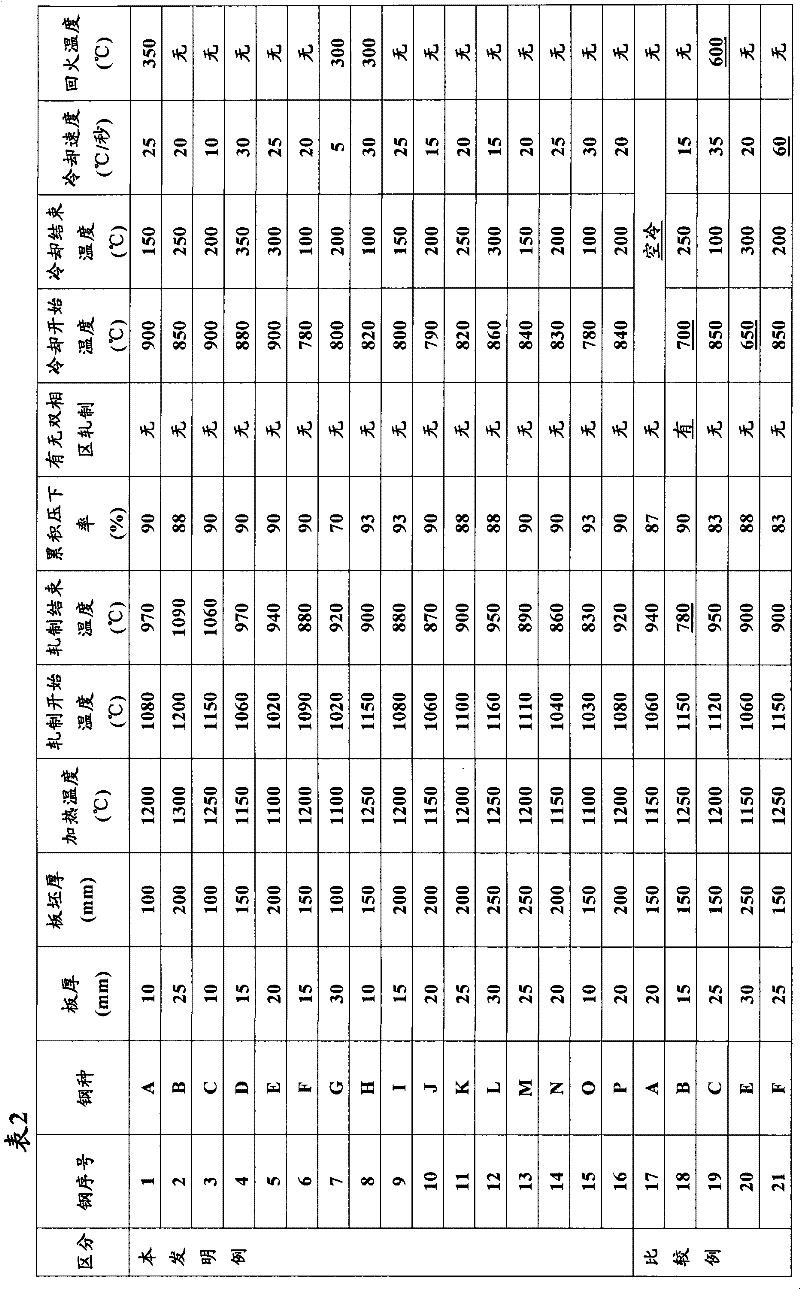

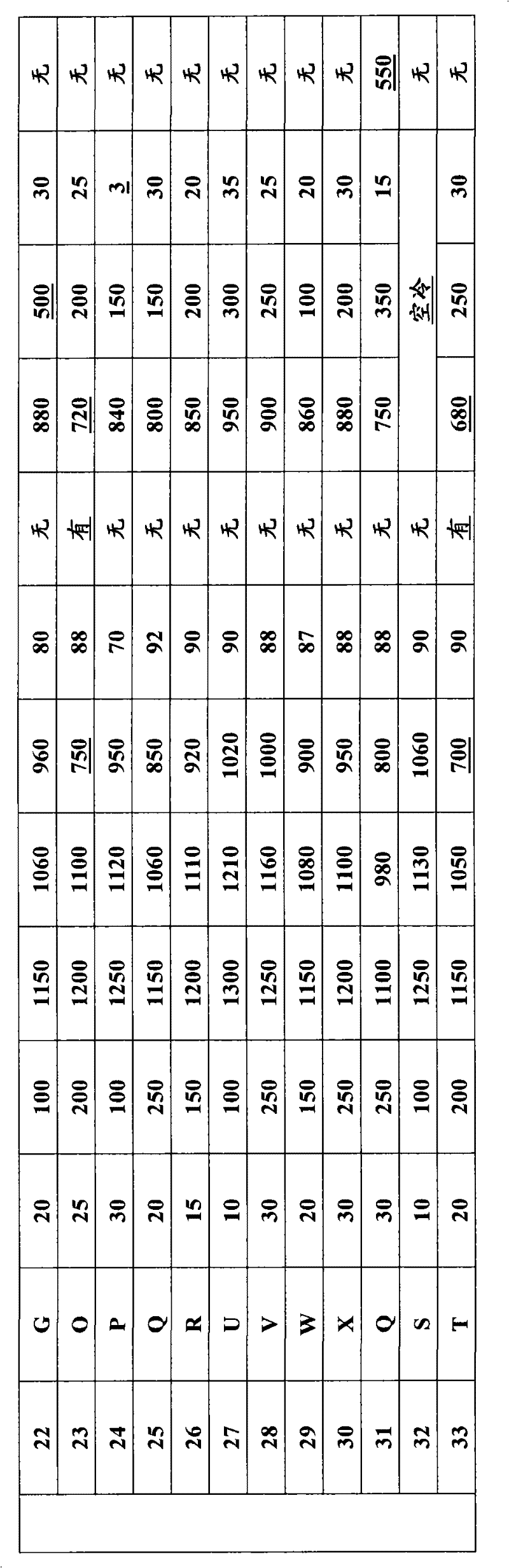

[0102] In the steelmaking process, the chemical composition of molten steel is adjusted, and then cast slabs are produced by continuous casting. Table 1 shows the chemical composition. Steel types A to P in the table are steel types satisfying the chemical composition requirements of the present invention, and steel types Q to X are steel types not satisfying the chemical composition requirements of the present invention. In addition, steel grades A to P satisfying the chemical composition requirements of the present invention contain Si≤0.02%, Mn≤0.03%, Cu≤0.03%, Ni≤0.03%, Cr≤0.04%, Mo≤0.004%, Nb≤0.002% %, V ≤ 0.002%, Ti ≤ 0.002%, B ≤ 0.0002%, Ca ≤ 0.0002%, Mg ≤ 0.0002%, REM ≤ 0.0001%. The quality is shown in Table 1. In addition, Ar in the table 3 The transformation point (°C) is obtained by applying heat to austenitizing treatment at 1200°C and then cooling at 0.5°C / sec using Fumasta test pieces prepared from these slabs. The value obtained from the thermal expansion cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com