Food improver for resisting starch ageing

A food improver and starch aging technology, applied in food science, dough processing, baking, etc., can solve the problems of less applied research and waste of resources, and achieve the effects of reducing aging speed, improving internal structure, and resisting starch aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of 100g heavy anti-starch aging food improver, its composition is as follows:

[0031] Calcium stearoyl lactylate 30g

[0032] Monoglyceride 30g

[0033] Potassium dihydrogen phosphate 15g

[0034] Fungal Xylanase 5g

[0035] Carrageenan 15g

[0036] Tricalcium Phosphate 5g

[0037] After the above-mentioned components are mixed in proportion to make the anti-starch anti-aging food improver of the present invention, add it to the flour according to the addition amount of 0.3% (weight), and produce bread according to the original production process. Under the production process conditions, no improver of the present invention is added to the flour to produce a control bread sample.

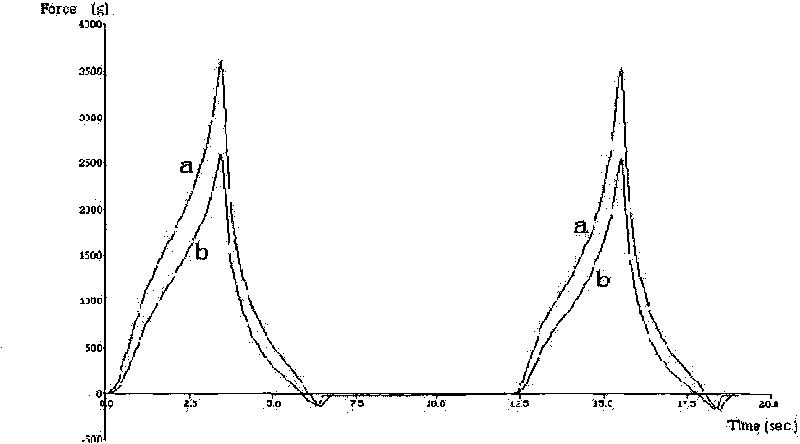

[0038] Using a physical property tester (Texture Analyzer XT2i), using SMSP / 35 probe, TPA program to measure the softness of fresh food with different storage time, and compare the results with the control food samples, where the vertical mark "gram" in the figure is the physical...

Embodiment 2

[0054] A kind of 100g heavy anti-starch aging improver, its composition is as follows:

[0055] Calcium stearoyl lactylate 38g

[0056] Monoglyceride 23g

[0057] Potassium dihydrogen phosphate 10g

[0058] Fungal Xylanase 6g

[0059] Carrageenan 20g

[0060] Tricalcium phosphate 1g

[0061] Silica 2g

[0062] After the above-mentioned components are mixed in proportion to make the anti-starch aging food improver of the present invention, add it to the flour according to the addition amount of 0.3% (weight), and produce the cake according to the original production process. Under the production process conditions, no improver of the present invention is added to the flour to produce a control cake sample.

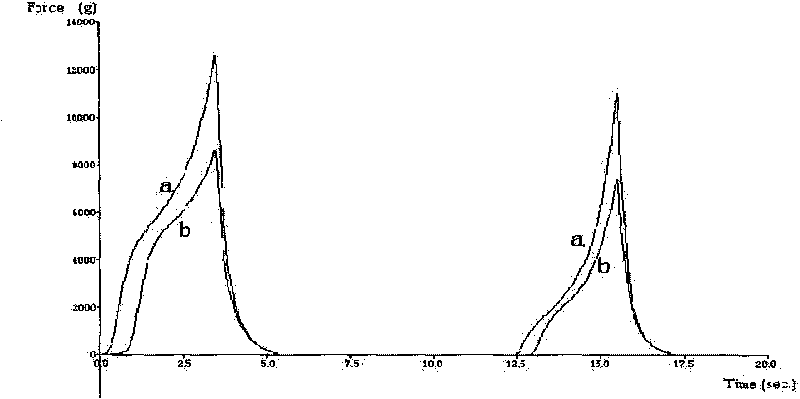

[0063] Physical property tester testing method is the same as embodiment 1, figure 2 The cake softness curve of this embodiment is tested by a physical property tester: a is a control cake sample, b is a fresh-keeping cake sample made after adding the anti-starch agin...

Embodiment 3

[0065] A kind of 100g heavy anti-starch aging improver, its composition is as follows:

[0066] Calcium stearoyl lactylate 40g

[0067] Monoglyceride 20g

[0068] Potassium dihydrogen phosphate 14g

[0069] Fungal Pentosanase 10g

[0070] Carrageenan 10g

[0071] Tricalcium Phosphate 4g

[0072] Silica 2g

[0073] After the above-mentioned components are mixed in proportion to make the anti-starch anti-aging food improver of the present invention, add it to the flour according to the addition amount of 0.3% (weight), and produce steamed buns according to the original production process. Under the production process conditions, no improver of the present invention was added to the flour to produce a control steamed bread sample.

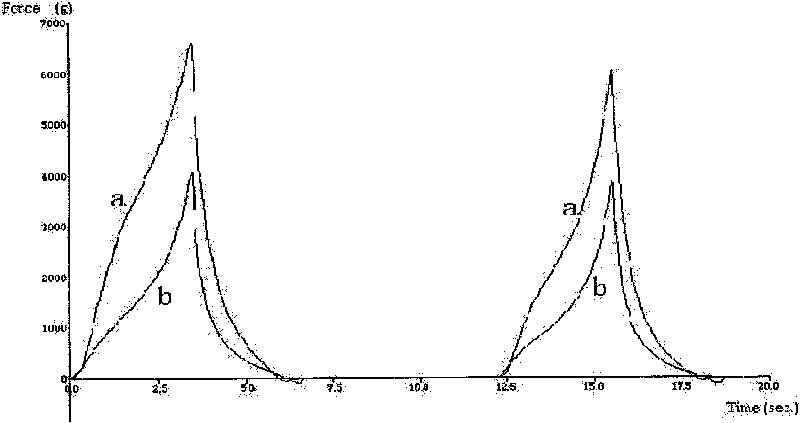

[0074] Physical property tester testing method is the same as embodiment 1, image 3 The steamed bread softness curve of this embodiment is tested by the physical property tester: a is the control steamed bread sample, b is the fresh-keeping st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com