Microcomputer based control device for constant-pressure atomization of pipeline

A technology of spray control and pipeline, which is applied in the direction of injection devices, etc., can solve the problems of different opening numbers of spray guns, reduce the effective adhesion of liquid medicine, and uneven atomization of droplets, so as to avoid the waste of liquid medicine, save labor, and reduce the pressure of liquid medicine. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

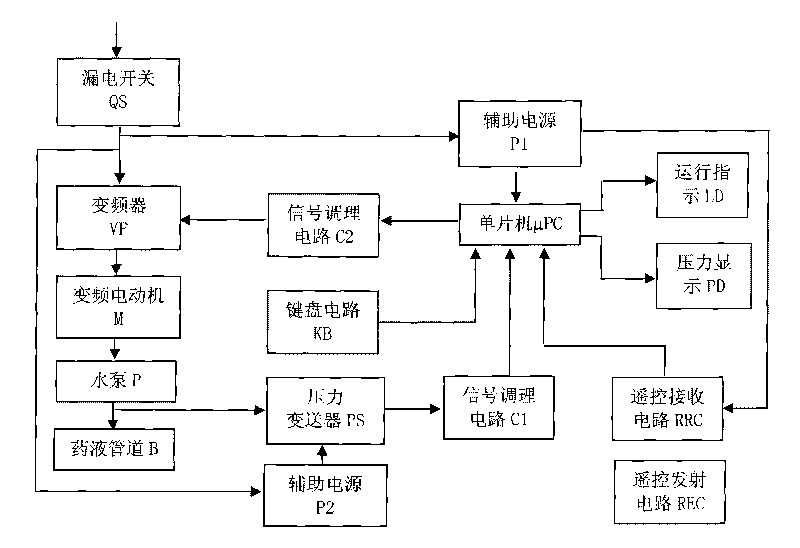

[0028] Such as figure 1 As shown, this microcomputer-based pipeline constant pressure spray control device includes leakage switch QS (that is, an automatic switch with leakage protection), frequency converter VF, single-chip microcomputer μPC, remote control transmitting circuit REC (that is, remote control), remote control receiving circuit RRC, pressure transmitter PS, signal conditioning circuit C1 and C2, pressure display gauge PD, operating status indicator LD, keyboard circuit KB, auxiliary power supply P1 and P2, the single-chip microcomputer and auxiliary power supply P1, remote control receiving circuit RRC, signal The conditioning circuit C1, the keyboard circuit KB, the pressure display gauge PD, the running status indicator light LD and the signal conditioning circuit C2 are respectively connected.

[0029] The three-phase power supply is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com